Manufacturing method of material tensile sample

A technology of tensile test specimen and production method, which is applied in the field of thin material tensile test specimen production to achieve the effects of high precision, improved processing speed, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The process embodiment will be described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0024] A method for making a material tensile sample, the method comprising the following steps:

[0025] A. According to the size of the standard tensile sample, make the stamping die of the punching machine whose gauge section width is larger than the gauge section width of the standard tensile sample;

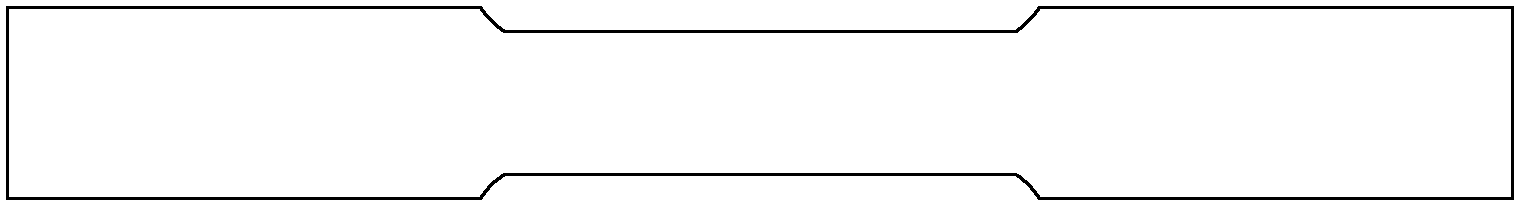

[0026] B. According to the properties and thickness of the material to be stamped, select a punching machine with the corresponding tonnage, and obtain a rough sample by punching the punching machine and stamping die, such as figure 1 As shown, the width of the gauge section of the rough sample is 15mm, and the width of the gauge section of the standard sample is 12.5mm;

[0027] C. Place the rough samples...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com