Distributed long gauge length optical fibre Bragg optical grating strain sensor and mfg. process thereof

A fiber Bragg and grating strain technology, applied in the coupling of optical waveguides, etc., can solve the problems of difficult structure detection, inability to effectively capture structures, failures, etc., to help durability and long-term stability, easy on-site installation, volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

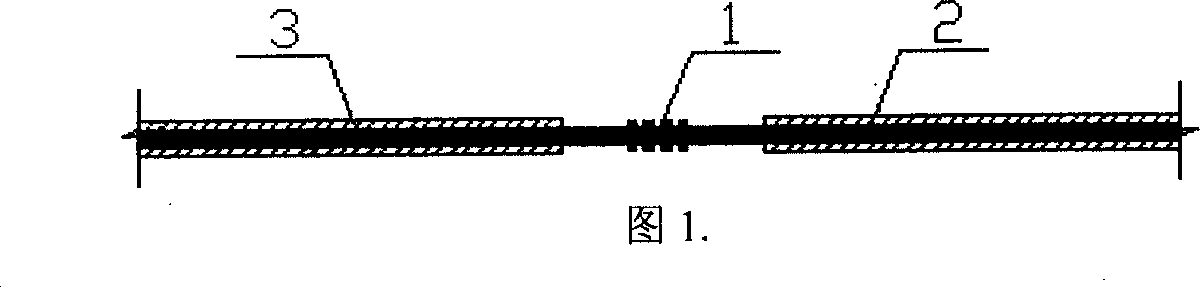

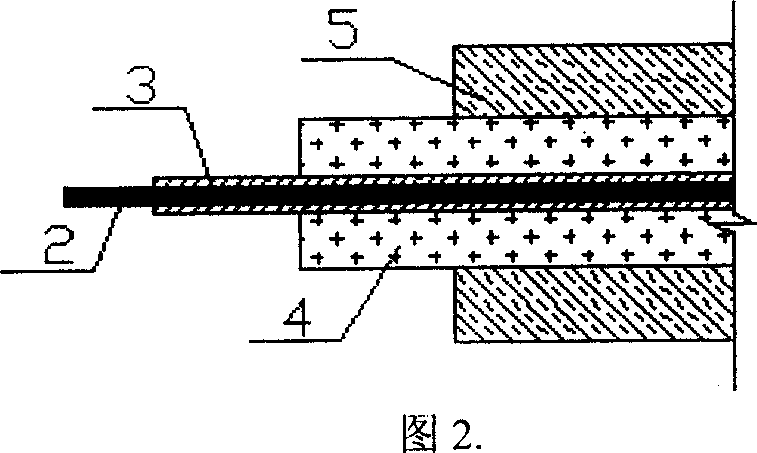

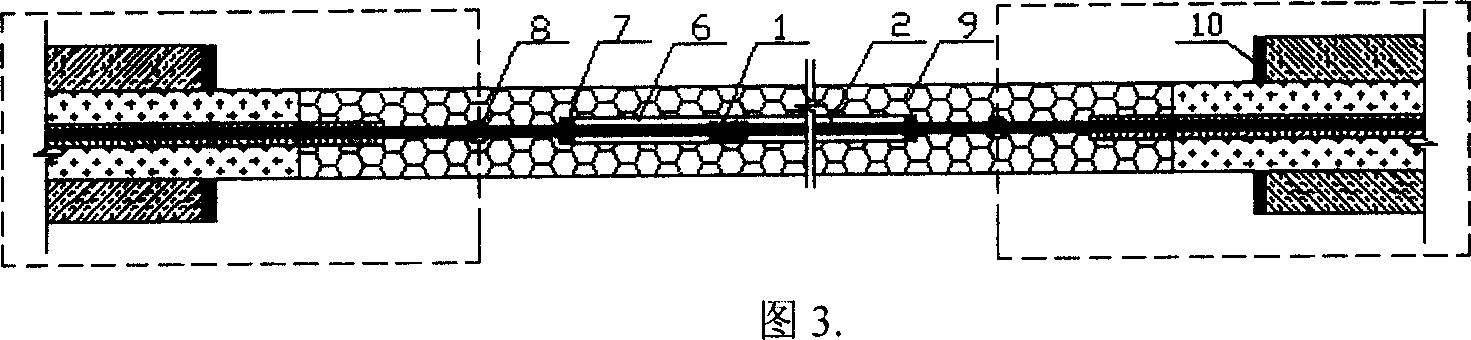

[0104] The strain sensor is composed of a plurality of long-gauge fiber Bragg grating 1 strain sensors in series; wherein a single long-gauge fiber Bragg grating 1 is connected to a single-mode optical fiber 2 with the coating removed at both ends of the fiber Bragg grating 1, and The outside of the fiber Bragg grating 1 and the single-mode optical fiber 2 with the coating removed is covered with a sleeve 6, and the two ends of the sleeve 6 are respectively fixed on the single-mode optical fiber 2 with the coating removed through the fixing points 7 between the optical fiber and the sleeve. The two ends of the single-mode optical fiber 2 from which the coating layer has been removed are respectively connected to the external single-mode optical fiber cable through fusion points 8, and the composite material encapsulation layer 9 is coated on the outside of the above structure. The surface of the fiber Bragg grating 1 is coated with a first heavy coating 11, the surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com