System and method for monitoring metal sample stress in high-temperature and high-pressure environment in real time

A metal sample, high temperature and high pressure technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to monitor strain and strain in real time, insufficient measurement accuracy, and achieve accurate real-time measurement of sample strain, wide application range, high The effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

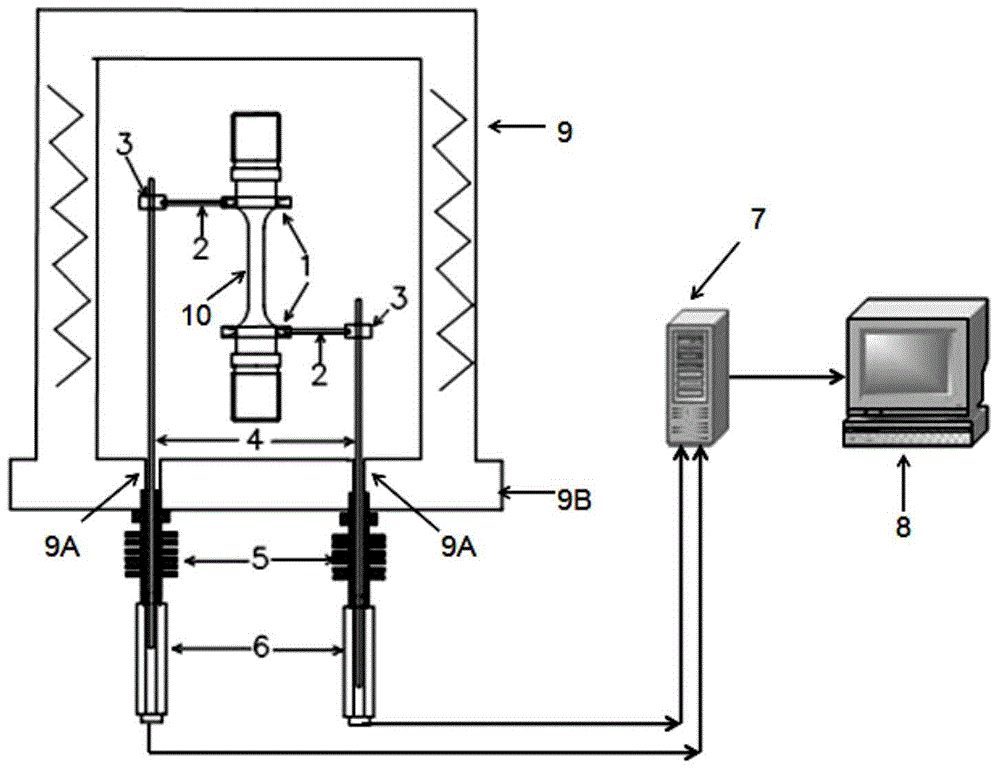

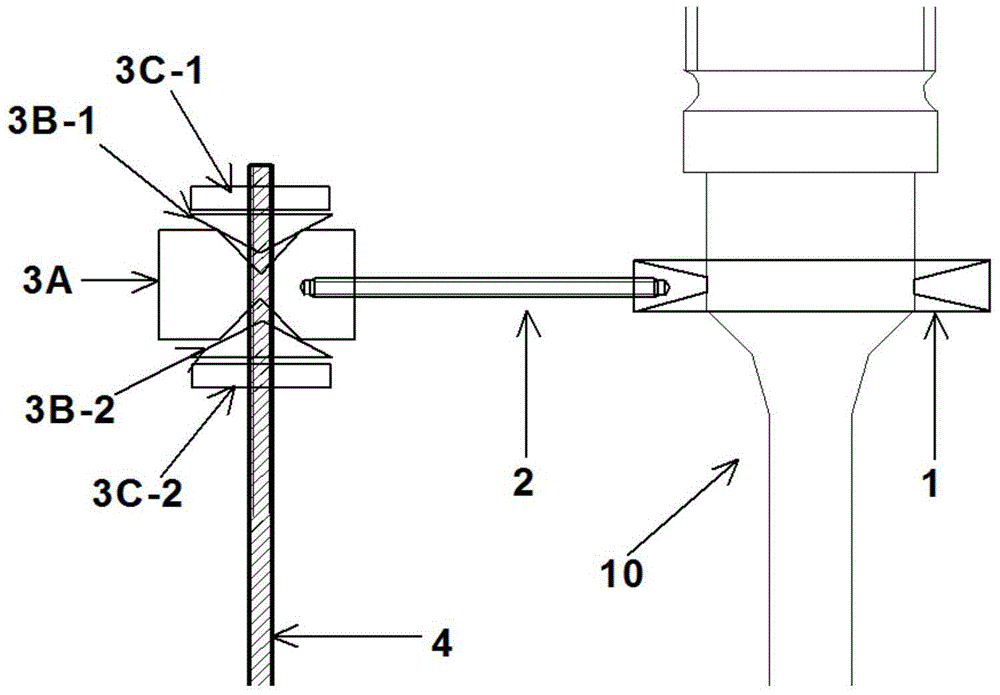

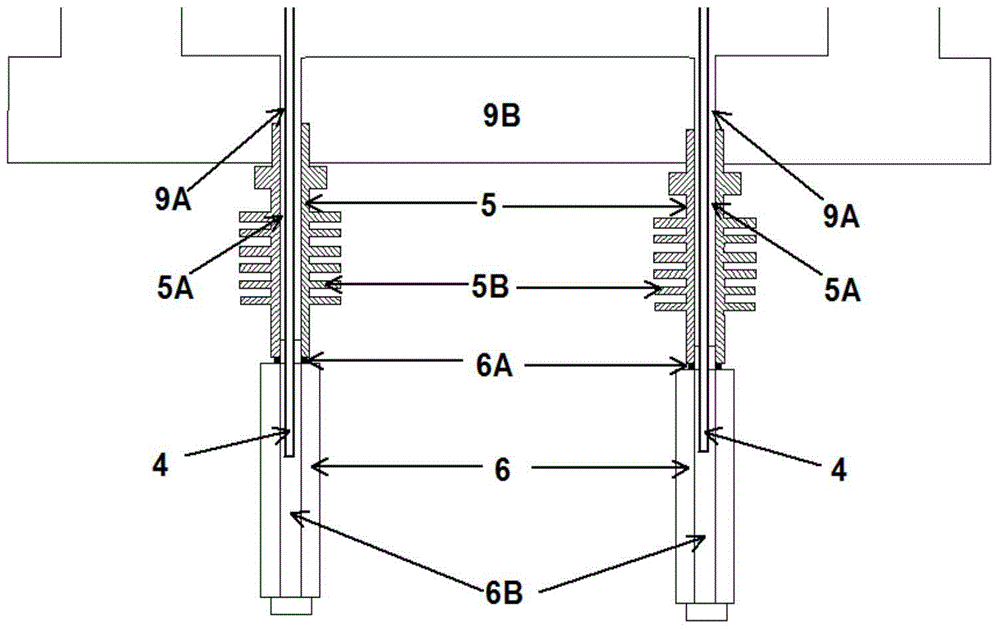

[0029] Such as figure 1 As shown, the present invention is a system for real-time monitoring of metal sample strain in high temperature and high pressure environment, including two sets of connecting component systems, two sets of displacement sensing systems and data acquisition systems, wherein each set of connecting component systems includes metal ohmic Clamp 1, connecting screw 2, fixed steering assembly 3 and induction core 4; each set of displacement sensing system includes: air cooling sleeve 5 and inductive extensometer 6; data acquisition system includes: signal amplifier 7 and signal collector 8 . The specific structure is as follows:

[0030] Both sets of connecting component systems are set in the high-temperature and high-pressure environment in the autoclave 9, wherein two metal ohmic clamps 1 are respectively clamped at the two ends of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com