A Method of Calibrating the Uniformity of Similar Materials Using Strain Bricks

A similar material and level technology, applied in the field of similar material simulation experiments, can solve the lack of uniformity in the density and porosity of similar material mechanical properties in the same layer, which affects the reliability and authenticity of similar material simulation tests, and cannot guarantee that each layer of similar materials In order to achieve the effect of low cost, easy data and low compaction degree, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

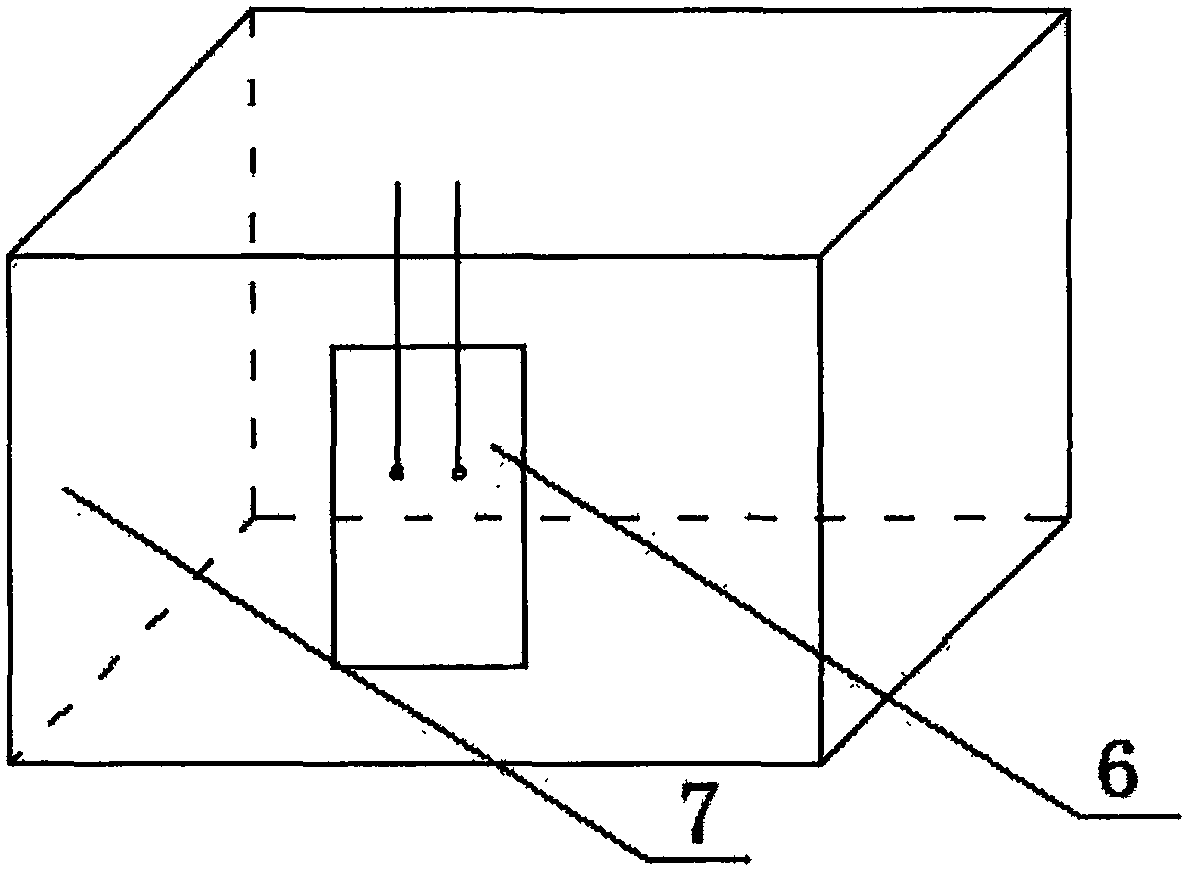

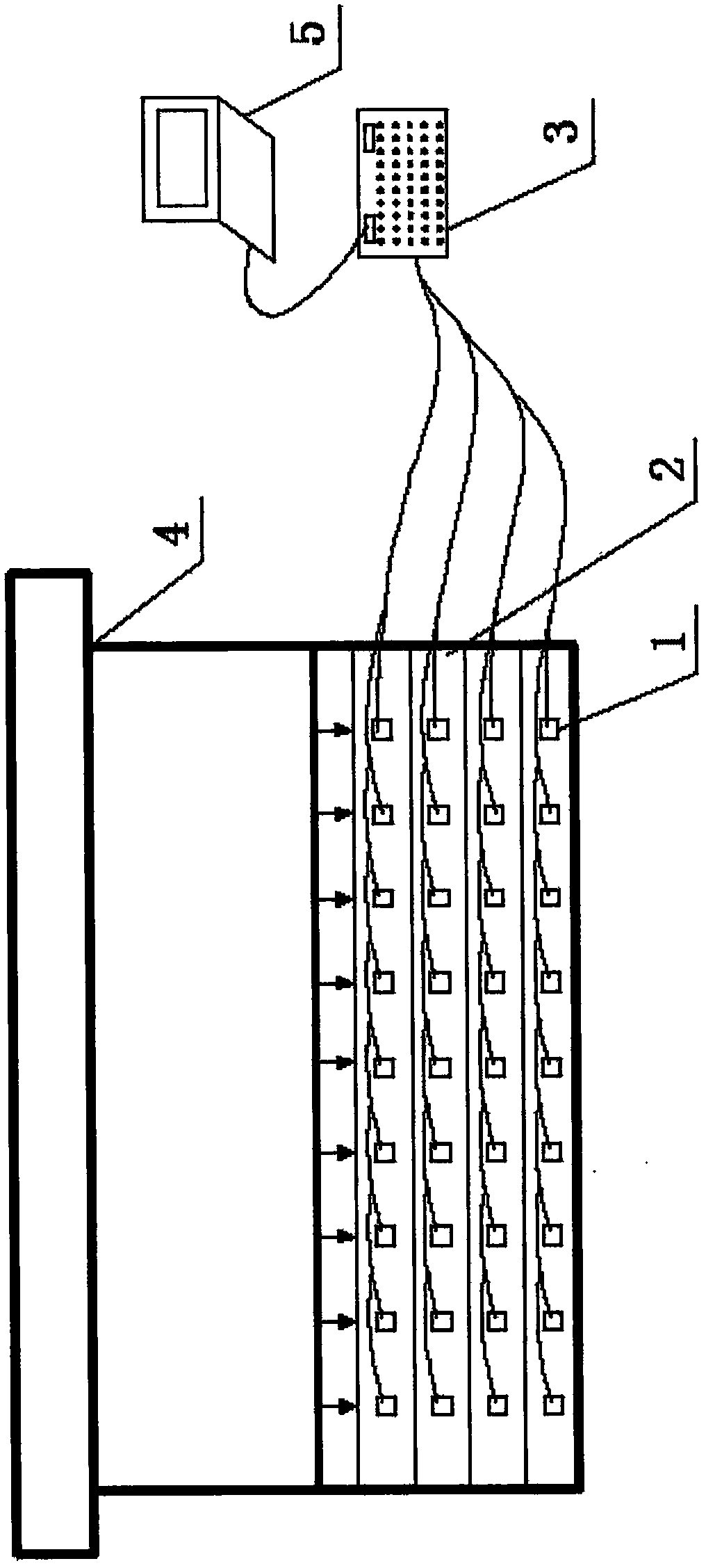

[0021] Such as figure 1 , 2 As shown, a method for calibrating the homogeneity of similar materials with strain bricks is characterized in that the equipment used includes several groups of strain bricks, plane stress test bench 4 and strain monitoring system, and each group of strain bricks consists of several strain bricks 1 composition;

[0022] The method for calibrating the homogeneity of similar materials includes the following steps:

[0023] Step 1: Layered laying: Layer similar materials and evenly lay them on the 4 plane stress test benches to construct a similar material body 2 with several layers, and in the process of laying similar materials, lay strained bricks During the laying process of similar materials in each layer, several strain bricks 1 are laid at equal intervals in the similar materials of the layer in turn for each layer;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com