Low-cost high-performance human motion sensor and preparation method thereof

A human motion, high-performance technology, applied in the field of sensors, can solve the problems of poor stretchability and low sensitivity, and achieve the effects of low cost, simple preparation process, and detection of large strains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a low-cost, high-performance human motion sensor and a preparation method thereof.

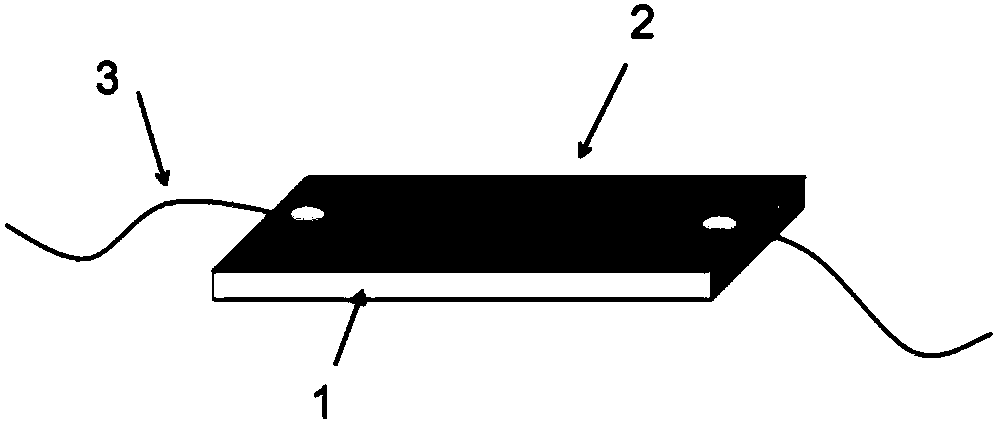

[0022] Such as figure 1 As shown, in the sensor, the strain-sensitive material 2 is uniformly covered on the stretchable flexible substrate 1 , and the wires 3 are connected to both ends of the strain-sensitive material 2 .

[0023] The stretchable flexible substrate 1 is obtained by solidifying liquid with a thickness of 1-3 mm, can be cut into any shape, and can be stretched to more than 3 times its own length. The strain-sensitive material 2 is a graphite particle film with a thickness of 50-200 μm, and the film is obtained from the film layer above the graphite particle suspension through a pulling method, which is repeated several times. The strain-sensitive material 2 of the low-cost, high-performance human body motion sensor has a wire 3 at both ends, and the wire 3 is fixed on the strain-sensitive material 2 through conductive silver glue. The strain sen...

Embodiment 1

[0030] Step 1: Curing the liquid flexible substrate Ecoflex 0030 from Smooth-On Company of the United States, the curing thickness is 2mm, and cutting the cured flexible substrate into a rectangular silicone substrate with a length of 30mm and a width of 10mm;

[0031] Step 2: Mix the graphite powder and deionized water at a ratio of 3g / 100ml to obtain a suspension, and then place the suspension in an ultrasonic cell pulverizer for ultrasonic treatment for 30 minutes, so that the graphite powder is evenly dispersed on the surface of the deionized water , forming a dense metallic graphite film with a thickness of about 10 μm;

[0032] Step 3: Put the flexible substrate described in step 1 under the graphite film on the surface of the graphite powder suspension described in step 2, and then pull it upwards, so that the graphite film, that is, the strain-sensitive material, is combined with the flexible substrate, and repeat this step 5 times to obtain a conductive film with a th...

Embodiment 2

[0037] Step 1: Curing the liquid flexible substrate Ecoflex 0050 from Smooth-On Company of the United States, the curing thickness is 3mm, and cutting the cured flexible substrate into a rectangular silicone substrate with a length of 50mm and a width of 20mm;

[0038] Step 2: Mix the graphite powder and deionized water at a ratio of 5g / 100ml to obtain a suspension, and then place the suspension in an ultrasonic cell pulverizer for ultrasonic treatment for 30 minutes, so that the graphite conductive powder is evenly dispersed in the deionized water On the surface, a dense graphite film with a thickness of about 20 μm is formed;

[0039] Step 3: Put the flexible substrate described in step 1 under the graphite film on the surface of the graphite powder suspension described in step 2, and then pull it upwards so that the graphite film is combined with the flexible substrate. Repeat this step 7 times to obtain the thickness A conductive film of about 110 μm, i.e. a strain-sensiti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com