Method of detecting asphalt pavement structure damage based on fiber grating sensors

A fiber grating and asphalt pavement technology, applied to instruments, roads, roads, etc., can solve the problems of high price, cost limitation, and inability to reuse, and achieve the effect of improving service life, high feasibility, and authentic and credible judgment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

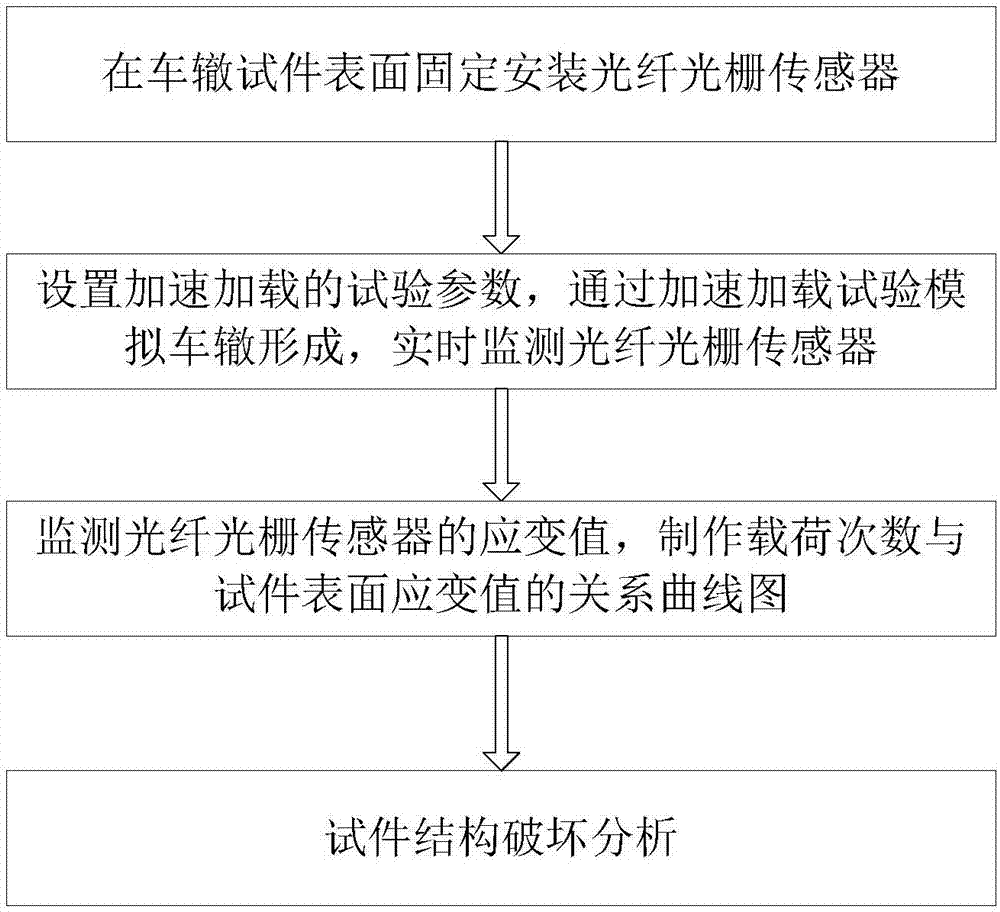

[0039] A damage monitoring method for asphalt pavement structure based on fiber Bragg grating strain sensor. The actual asphalt pavement structure is simulated according to the indoor rutting test, and the loading process of the pavement is simulated through the accelerated loading test. The pavement cracking caused by the rutting of the specimen is reflected by the surface strain, and the structural damage of the pavement is analyzed in combination with the rutting displacement.

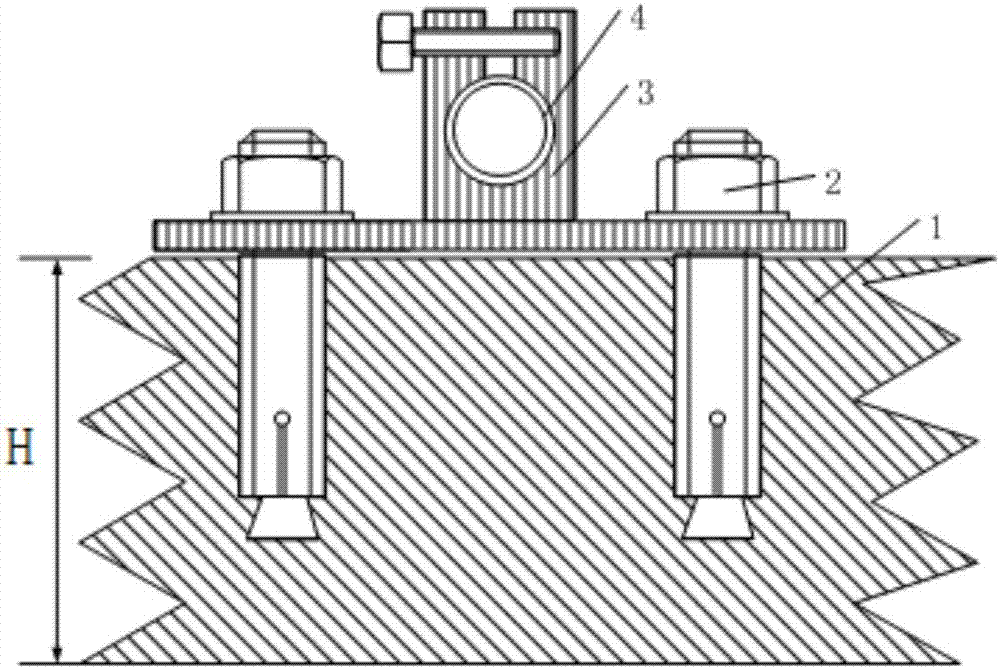

[0040] In order to test the feasibility of the fiber grating surface strain sensor and monitoring method, according to road construction experience, the rutting specimen gradation adopts AC-13, the asphalt is domestic No. 70 matrix, and the asphalt ratio is 4.8%, simulating the upper layer of asphalt expressway structure. The rutting specimens were formed by the T0702-2011 asphalt mixture specimen preparation method (wheel rolling method) in the "Test Regulations for Asphalt and Asphalt Mixtures in ...

Embodiment 2

[0057] A damage monitoring method for asphalt pavement structure based on fiber Bragg grating strain sensor. The actual asphalt pavement structure is simulated according to the indoor rutting test, and the loading process of the pavement is simulated through the accelerated loading test. At the same time, the surface strain of the rutting specimen is detected in real time by the fiber grating surface strain sensor. , the pavement cracking caused by the rutting of the specimen is reflected by the surface strain, and the pavement rutting failure is analyzed in combination with the rut depth.

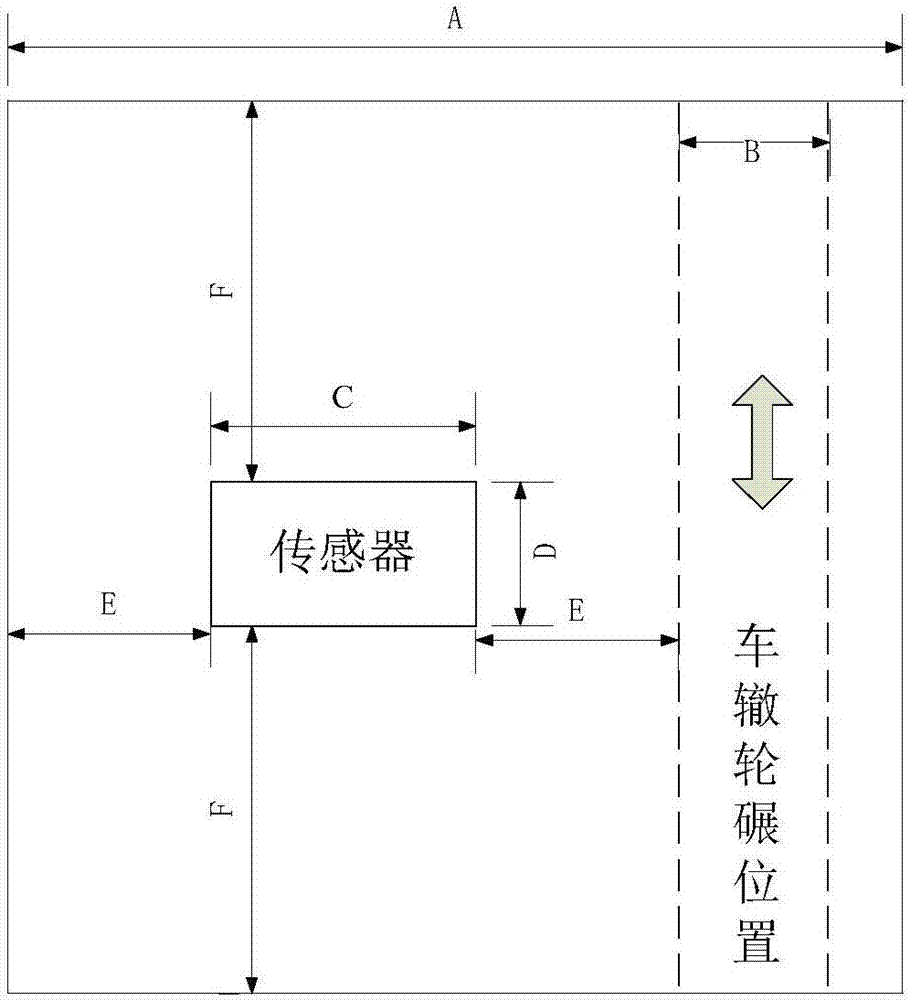

[0058] In order to better simulate the actual pavement structure, the combined rutting test piece is divided into upper, middle and lower surface layers, and the size of the test mold is 1m×0.5m; the bottom of the lower layer uses epoxy resin to paste limestone gravel to simulate the base structure. The thickness is not more than 1cm. The gradation of each layer from bottom to top is AC-25...

Embodiment 3

[0074] A method for monitoring the damage of asphalt pavement structure based on fiber grating strain sensor, which is characterized in that the actual asphalt pavement structure is simulated according to the indoor rutting test, the loading process of the pavement is simulated through the accelerated loading test, and the rutting test is monitored in real time by the fiber grating surface strain sensor The surface strain of the specimen is used to reflect the pavement cracking caused by rutting of the specimen through the surface strain, and the rutting damage of the pavement is analyzed in combination with the rut depth.

[0075] In order to better simulate the actual pavement structure, the combined rutting test piece is divided into upper, middle and lower surface layers, and the size of the test mold is 1m×0.5m; the bottom of the lower layer uses epoxy resin to paste limestone gravel to simulate the base structure. The thickness is not more than 1cm. The gradation of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com