Automobile headlamp structure fatigue life analysis method

A fatigue life analysis, automotive headlight technology, used in the testing of machine/structural components, measuring devices, instruments, etc., can solve the problem of load accuracy, low fatigue life accuracy of headlights, and cannot consider temperature changes. The impact of structure and other issues can save costs and shorten the development cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

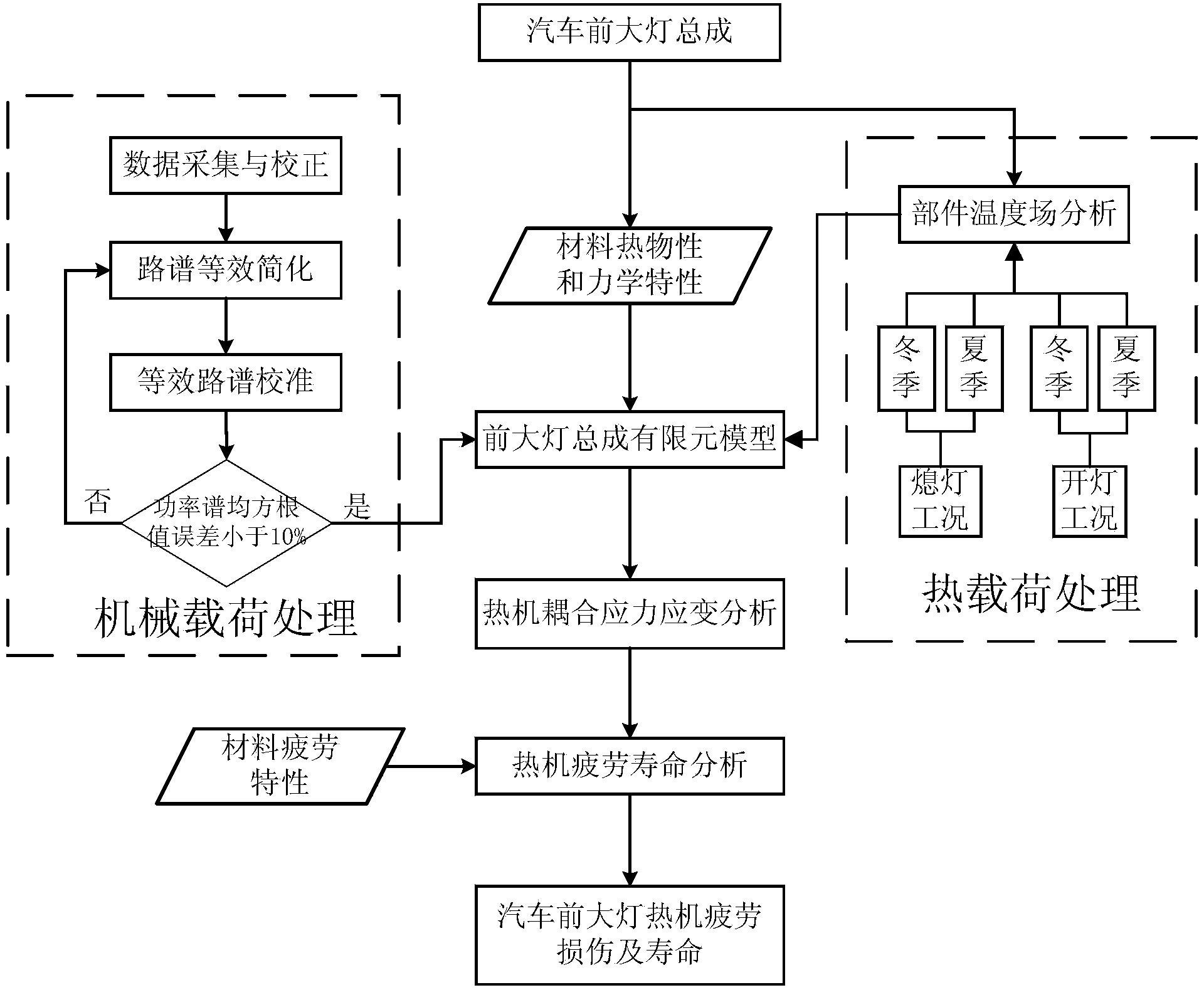

[0021] like figure 1 The fatigue life analysis method for the automobile headlight structure includes the following steps:

[0022] Step 1. Headlight mechanical load processing

[0023] 1a. Acquisition and correction of road spectrum data: install a three-way vibration acceleration sensor at the connection between the headlights and the body, according to the road section requirements of the vehicle road reliability test at the proving ground (this road section consists of pothole roads, pebble roads, washboard roads and Road spectrums of roads of different grades such as Belgian roads combined in proportion), collect combined road spectra of different grades of roads, use high-pass filtering method, balanced skew method and least squares method to correct the collected road spectrum data, and eliminate Singularities and trend terms due to systematic disturbances. The sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com