Energy-saving slag thermal insulator

A technology of heat preservation agent and slag, which is applied in the field of energy-saving heat preservation agent, and can solve the problem of no recycling and utilization of heat energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

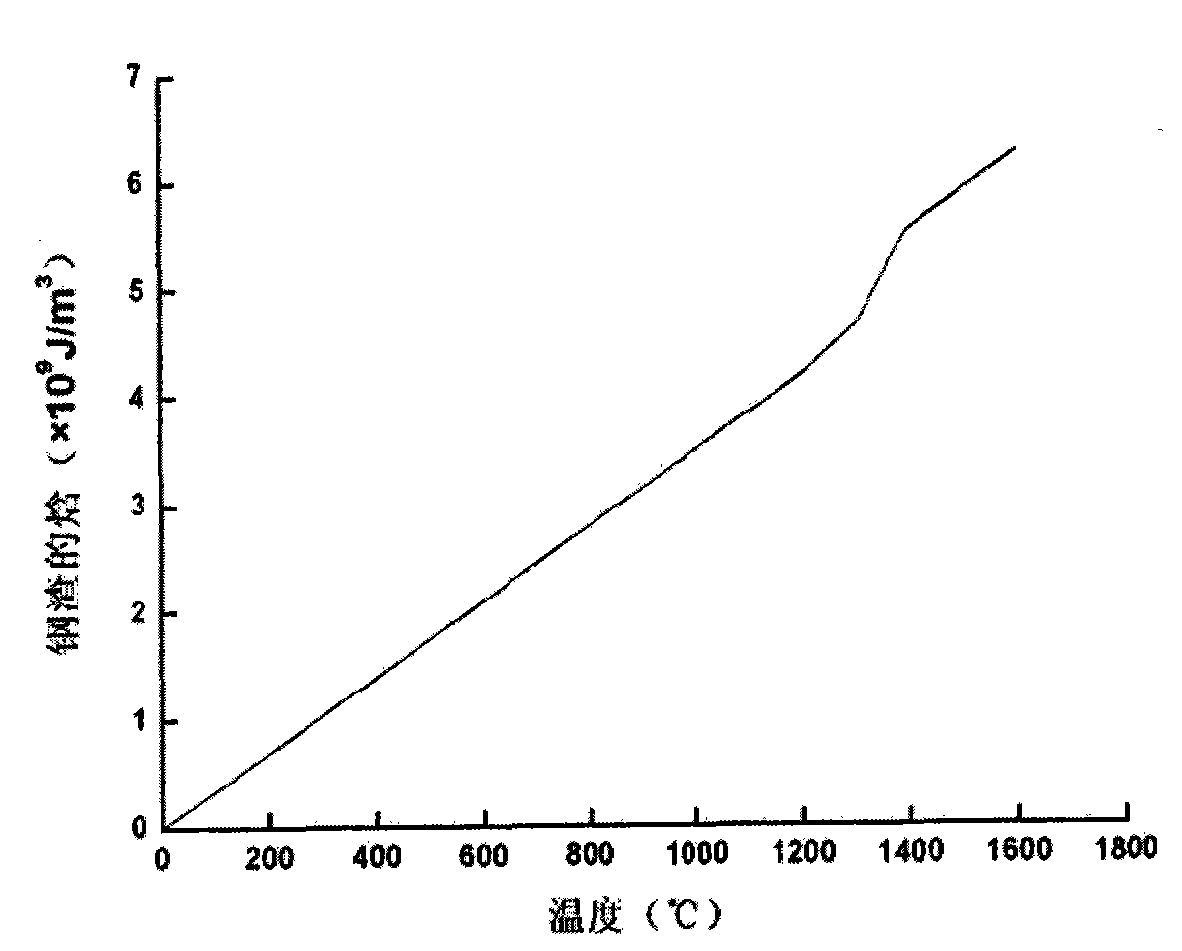

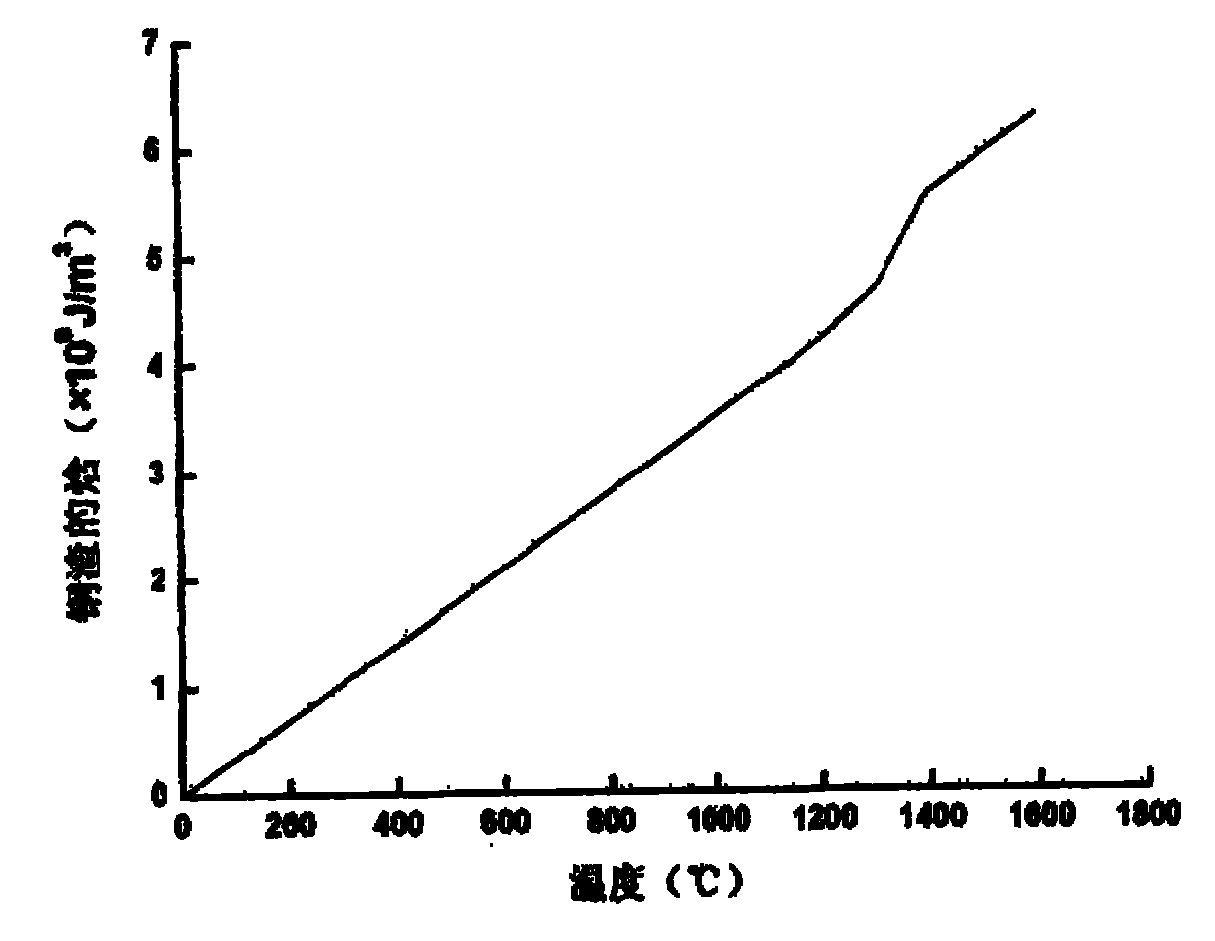

Image

Examples

Embodiment 1

[0014] Embodiment one: carbonized rice husk is used as energy-saving heat preservation agent, and its composition is 39.8% SiO 2 , 3.9% Al 2 o 3 , 2.5% CaO, 2.2% MgO, 9.2% Fe 2 o 3 , 1.6% R 2 O (R is a monovalent metal ion), 40.0% fixed carbon, 0.7% other components. When the energy-saving thermal insulation agent is applied to molten blast furnace slag, crusting on the surface of the molten blast furnace slag is reduced and fluidity is improved.

Embodiment 2

[0015] Example 2: Coke powder, carbonized rice husk and fluorite are prepared as an energy-saving and thermal insulation agent, which consists of 21.69% SiO 2 , 4.0% Al 2 o 3 , 5.7% CaO, 1.2% MgO, 2.6% F-, 5.2% Fe 2 o 3 , 0.8% R 2 O (R is a monovalent metal ion), 58.3% of fixed carbon, 0.2% of other components. When the energy-saving thermal insulation agent is applied to molten blast furnace slag, the crusting phenomenon on the surface of molten slag is reduced and the fluidity is improved.

Embodiment 3

[0016] Embodiment 3: Perlite, coke powder, fly ash and fluorite are prepared as energy-saving thermal insulation agent, and its composition is 36.3% SiO 2 , 18.0% Al 2 o 3 , 7.2% CaO, 0.7% MgO, 3.6% F - , 4.5% Fe 2 o 3 , 1.7% R 2 O (R is a monovalent metal ion), 11.6% of fixed carbon, 1.7% of other components. The energy-saving thermal insulation agent was added to the surface of high-temperature molten steel slag, and the results showed that the temperature of the molten slag added with thermal insulation agent was 1604°C during slag discharge, and the slag temperature was 1550°C during slag pouring, and the molten slag had good fluidity.

[0017] Under the same conditions, the temperature of the slag without heat preservation agent was 1623°C when it was discharged, and the temperature of the slag was 1480°C when it was poured, and the fluidity of the slag was poor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com