Low cost active powder concrete and preparation thereof

A technology of active powder and concrete, which is applied in the direction of clay preparation equipment, mixing operation control, chemical instruments and methods, etc., can solve the problems of insufficient resource distribution and total number, lack of theoretical research and theoretical innovation, low reactivity of quartz powder, etc., to achieve Reduce the cost of raw materials and maintenance costs, facilitate the promotion and application, and reduce the effect of molding maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

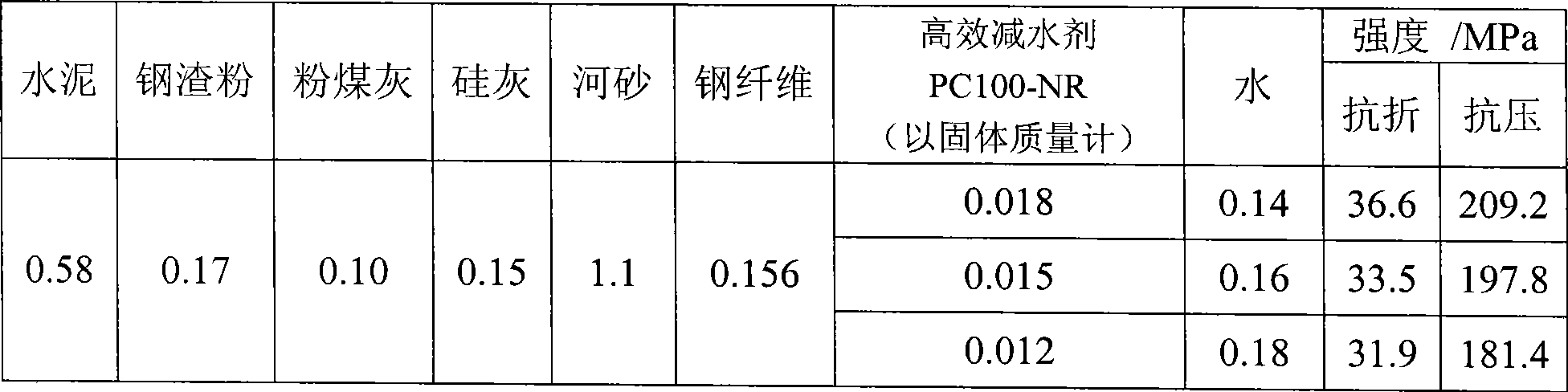

example 1

[0019] Low-cost active powder concrete, which is prepared from cement, steel slag powder, fly ash, silica fume, superplasticizer, river sand, mixing water and steel fiber by the following methods:

[0020] 1) Select cement, steel slag powder, fly ash, silica fume, polycarboxylate superplasticizer, river sand, mixing water and steel fiber. Among them, the cement is P.I42.5 produced by Gezhouba Co., Ltd., the 28d compressive strength is 57.3MPa, and the flexural strength is 6.5MPa; the steel slag powder is produced by Wuhan Iron and Steel Green Metallurgical Slag Co., Ltd., and the alkalinity coefficient is K a (CaO / (SiO 2 +P 2 o 5 )) is 3.2, and the specific surface area is 541m 2 / kg; Fly ash is Class I fly ash of Wuhan Qingshan Power Plant and is ground by a ball mill to a specific surface area of 659m 2 / kg, the water demand ratio is 90%; silica fume is provided by Wuhan Haoyuan Chemical Building Materials Co., Ltd., with a specific surface area of 20,000m 2 / kg, aver...

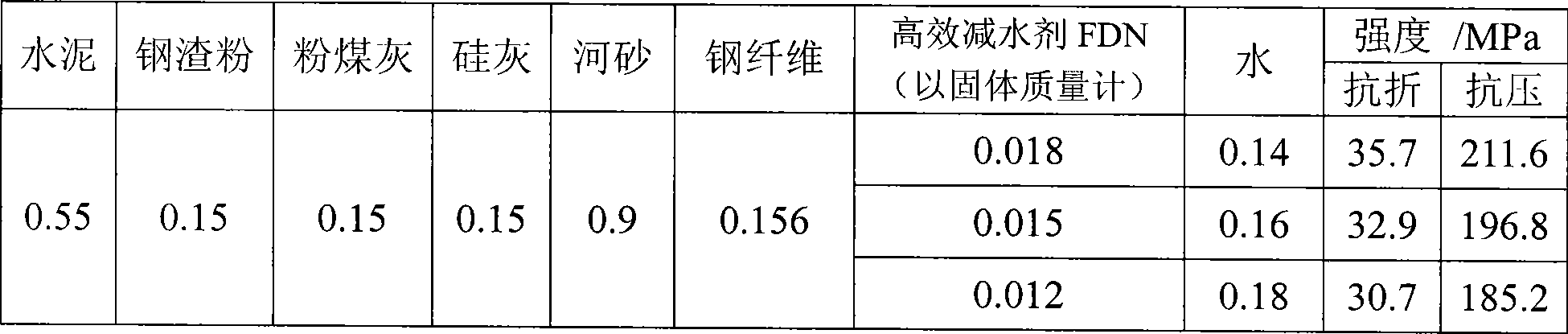

example 2

[0026] Low-cost active powder concrete, which is prepared from cement, steel slag powder, fly ash, silica fume, superplasticizer, river sand, mixing water and steel fiber by the following methods:

[0027] 1) Select cement, steel slag powder, fly ash, silica fume, high-concentration naphthalene-based superplasticizer, river sand, mixing water and steel fiber. Among them, the cement is P.O52.5 produced by Gezhouba Co., Ltd., the 3d compressive strength is 29.6MPa, and the 28d compressive strength is 61.5MPa; the steel slag powder is produced by Wuhan Iron and Steel Green Metallurgical Slag Co., Ltd., and the alkalinity coefficient is K a (CaO / (SiO 2 +P 2 o 5 )) is 3.4, and the specific surface area is 514m 2 / kg; Fly ash is Class I fly ash of Wuhan Yangluo Power Plant, and it is ground by a ball mill to a specific surface area of 694m 2 / kg, the water demand ratio is 90%; silica fume is provided by Wuhan Haoyuan Chemical Building Materials Co., Ltd., with a specific surfa...

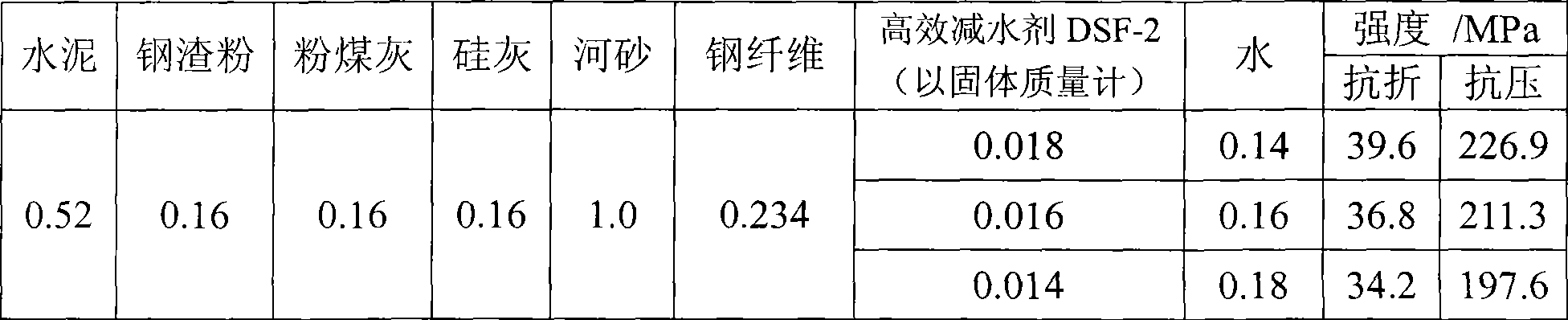

example 3

[0033] Low-cost active powder concrete, which is prepared from cement, steel slag powder, fly ash, silica fume, superplasticizer, river sand, mixing water and steel fiber by the following methods:

[0034] 1) Select cement, steel slag powder, fly ash, silica fume, soluble resin type superplasticizer, river sand, mixing water and steel fiber. Among them, the cement is P.O52.5 cement produced by Gezhouba Co., Ltd., the 3d compressive strength is 31.6MPa, and the 28d compressive strength is 67.5MPa; the steel slag powder is produced by Wuhan Iron and Steel Green Metallurgical Slag Co., Ltd., and the alkalinity coefficient is K a (CaO / (SiO 2 +P 2 o 5 )) is 3.2, and the specific surface area is 541m 2 / kg; Fly ash is Class I fly ash of Wuhan Qingshan Power Plant and is ground by a ball mill to a specific surface area of 659m 2 / kg, the water demand ratio is 90%; silica fume is provided by Wuhan Haoyuan Chemical Building Materials Co., Ltd., with a specific surface area of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com