Control method for coast atmospheric corrosion resistant scale on surface of boat deck

A technology of iron oxide scale and atmospheric corrosion, applied in the direction of temperature control, heat treatment process control, workpiece surface treatment equipment, etc., can solve the problems of unqualified surface state, unqualified size, economic loss, etc., to inhibit pitting corrosion, improve plasticity, The effect of extending the storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

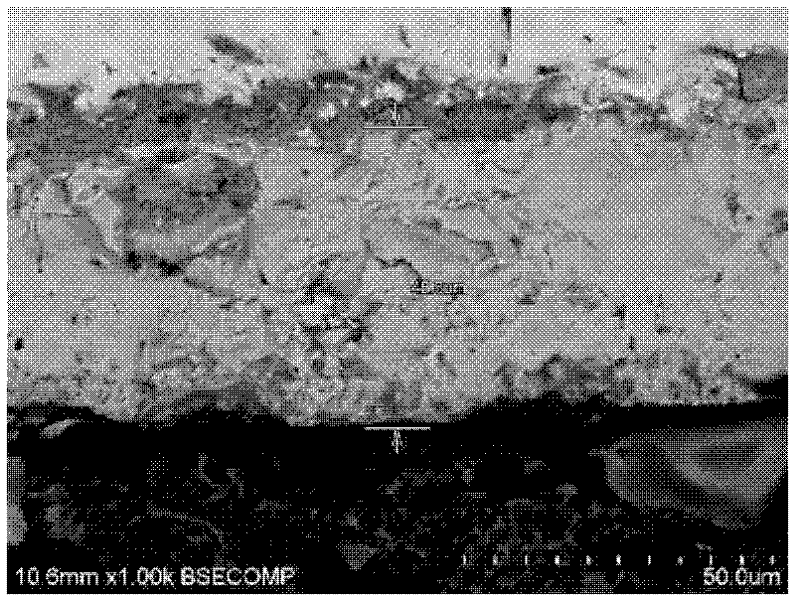

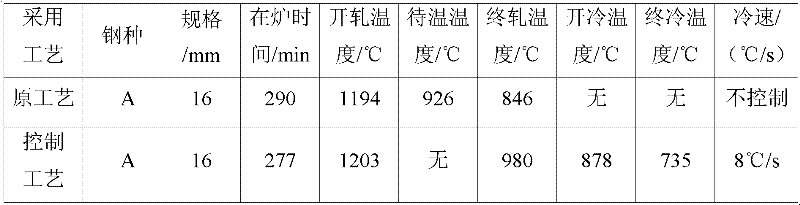

[0030]As shown in Table 1, the scale control process parameters in Example 1 are shown. Compared with the original process, the time of slab in the furnace is shortened, the thickness and structure of primary oxide scale are improved, and the effect of primary descaling is enhanced. Increase the finish rolling temperature, enhance the descaling effect in the finish rolling process, avoid scale intrusion, and further improve the surface quality of ship plates. Use the weak water cooling system to increase the adhesion between the oxide scale and the substrate, and reduce the Fe during the cooling process. 3 o 4 Excessive conversion to Fe 2 o 3 , to increase Fe in oxide scale 3 o 4 content. Table 2 is the structure (wt%) of the iron oxide scale under different processes, the thickness of the iron oxide scale in the control process is about 40μ, and the iron oxide scale in the iron oxide scale is 3 o 4 The content reaches 55%, obviously higher than the original process. ...

Embodiment 2

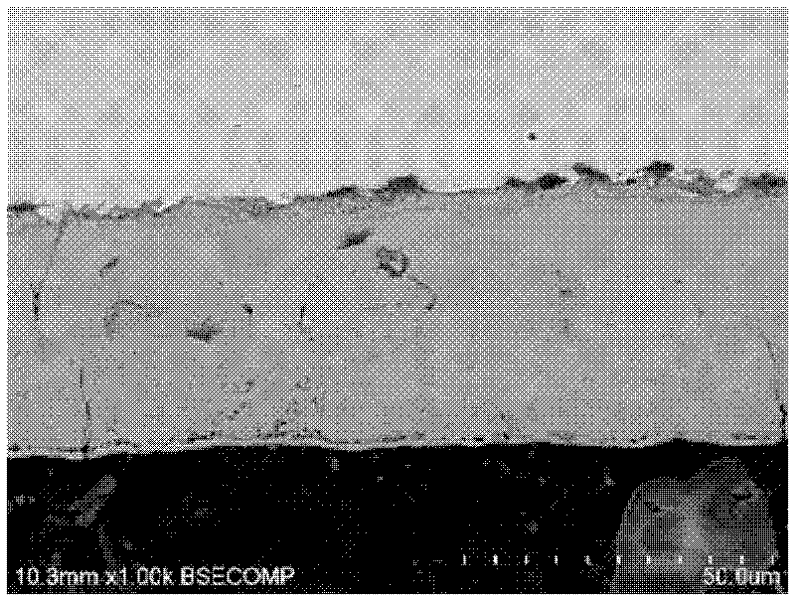

[0038] Table 4 is the scale control process parameters in Example 2. Compared with the original process, the time of slab in the furnace is shortened, the thickness and structure of primary oxide scale are improved, and the effect of primary descaling is enhanced. Increase the finish rolling temperature, enhance the descaling effect in the finish rolling process, avoid scale intrusion, and further improve the surface quality of ship plates. Increase the cooling temperature, use the weak water cooling system to increase the adhesion between the oxide scale and the substrate, and reduce the Fe during the cooling process. 3 o 4 Excessive conversion to Fe 2 o 3 , to increase Fe in oxide scale 3 o 4 content. Table 5 is the structure (wt%) of the iron oxide scale under different processes, the thickness of the iron oxide scale in the control process is about 40 μ, and the Fe in the iron oxide scale under the control process 3 o 4 The content reaches 50%, obviously higher tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com