Water surface floating oil recovery ship

A technology for oil slicks on the water surface and recovery ships, which is applied to special-purpose ships, ships, motor vehicles, etc. It can solve the problems of oil slick viscosity requirements, easy to cause blockage, and poor effect, so as to improve the oil sweeping surface and reduce emulsification High efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

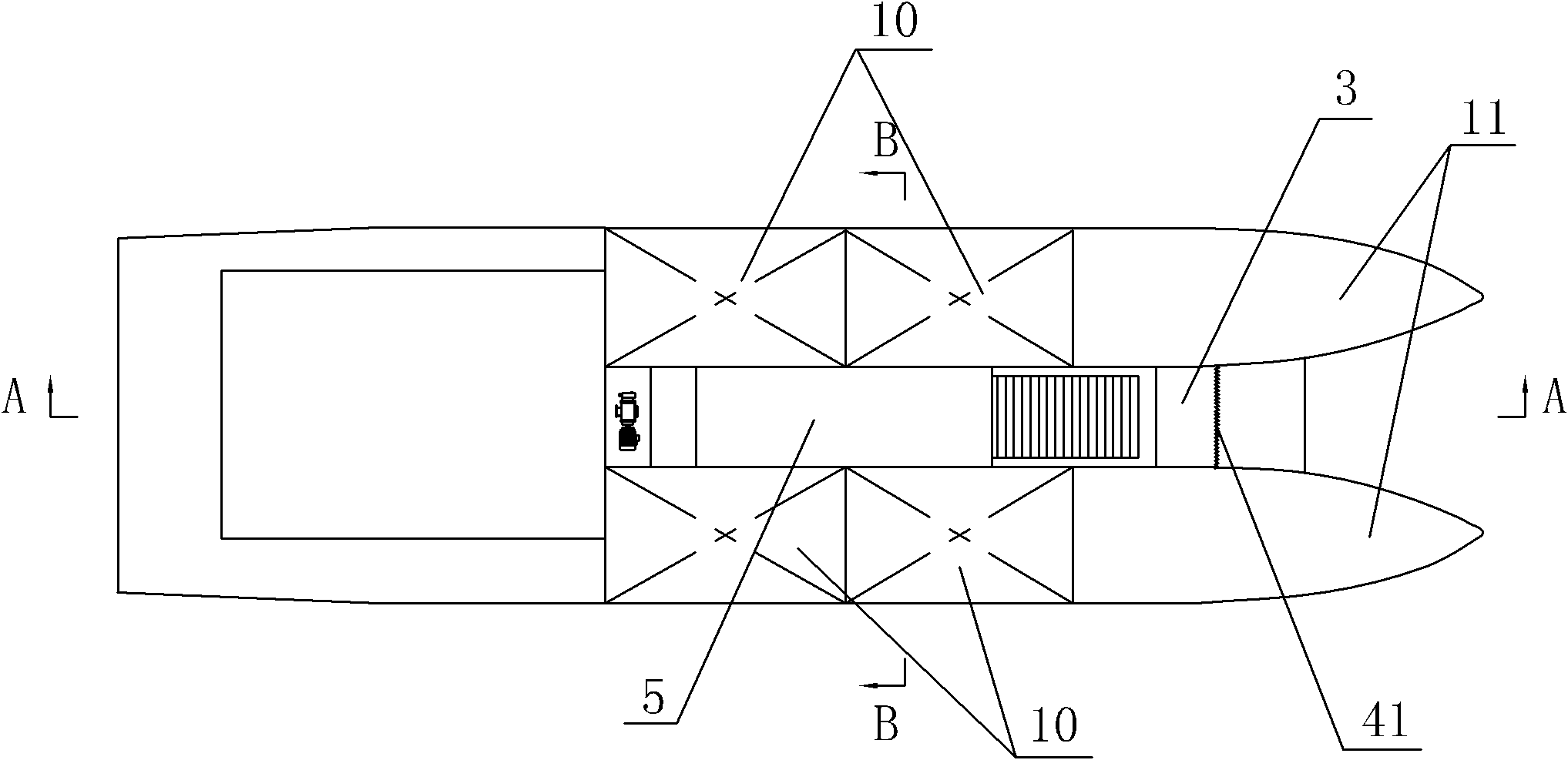

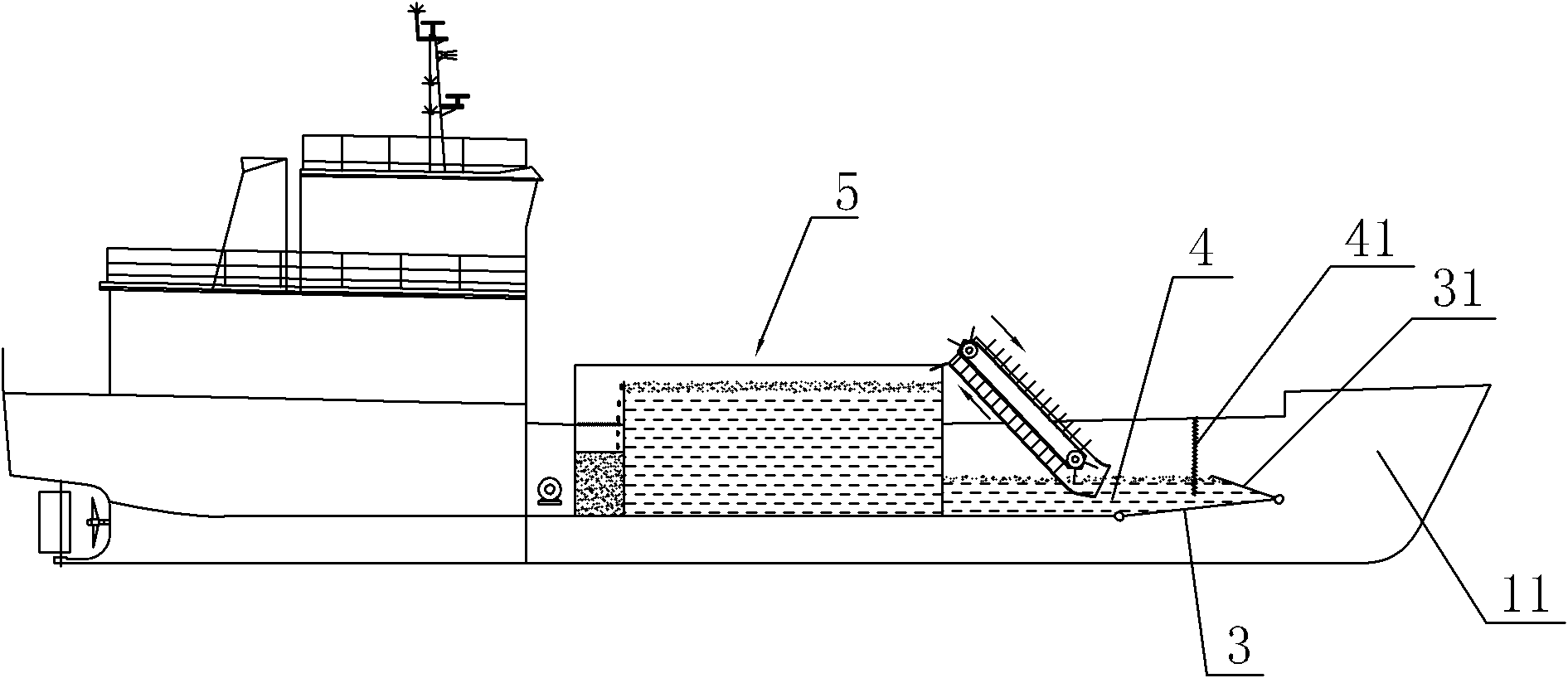

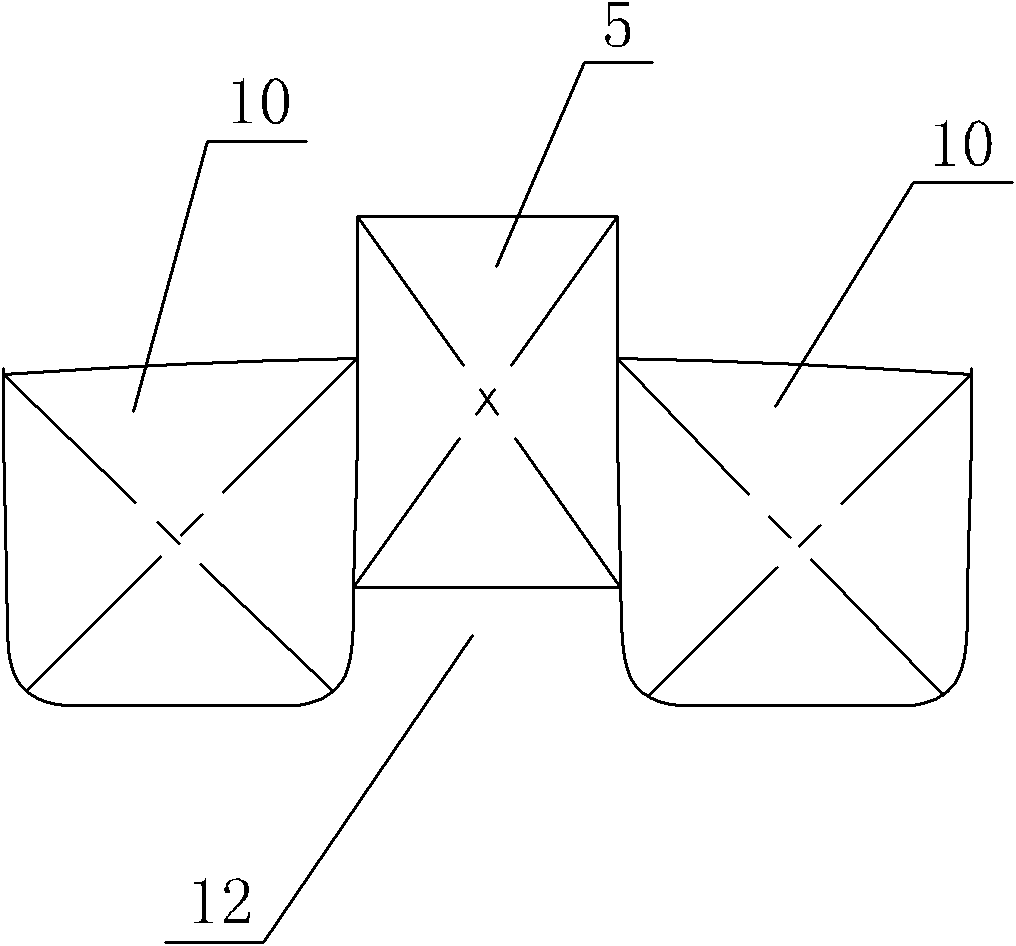

[0020] As shown in the figure, a surface oil slick recovery ship includes a hull, an oil slick collection device, and an oil-water separation device 5. The oil-water separation device 5 includes an oil-water separation bin 51 and an oil collection bin 52. The bow 11 of the hull is a catamaran structure, the bow 11 is in the shape of a sharp cone, the middle part of the hull to the stern is a monohull structure, and the bottom of the monohull structure part is provided with an inwardly concave longitudinal diversion channel 12, and the floating oil collection device includes a chain type The oil slick lifting device and the oil water pool 4 arranged in the middle of the hull, the water inlet of the oil water pool 4 is hinged with a water inlet baffle 3, the water inlet baffle 3 is located in the middle of the catamaran structural part, the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com