An eccentric oil well pump

An oil well pump and eccentric technology, which is applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of long oil inlet channel and large oil inlet resistance, and achieve the effect of reducing oil inlet resistance and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

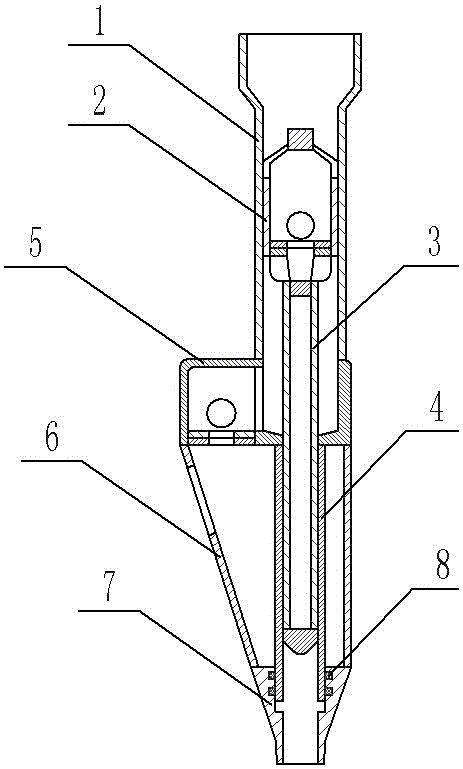

[0015] The embodiment of eccentric oil well pump among the present invention: as figure 1 As shown, the eccentric oil well pump is an eccentric bridge oil well pump used in thermal recovery of heavy oil wells in oil fields, including an upper pump barrel 1, an eccentric joint 5, a lower pump barrel 4, and a conversion joint 7 sequentially connected from top to bottom. , the upper pump barrel 1 and the lower pump barrel 4 are slidingly assembled with the upper plunger 2 and the lower plunger 3 along the up and down direction, the upper plunger 2 and the lower plunger 3 are connected to each other, and the upper and lower ends of the lower plunger 3 Both are closed; the eccentric joint 5 has a central part connected between the upper pump cylinder 1 and the lower pump cylinder 4 and an eccentric part offset to one side of the central part, and the eccentric part is equipped with a device for controlling the one-way flow of oil from bottom to top. The fixed valve is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com