A kind of parallel double-chamber oil well pump

A parallel type, oil well pump technology, applied in the direction of variable displacement pump components, pumps, pump components, etc., can solve the problems of high energy consumption, the inability of rod pumps to achieve large displacement lifting, and the high cost of electric pump lifting. Achieve the effect of improving pump efficiency, increasing downward power and reducing oil inlet resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

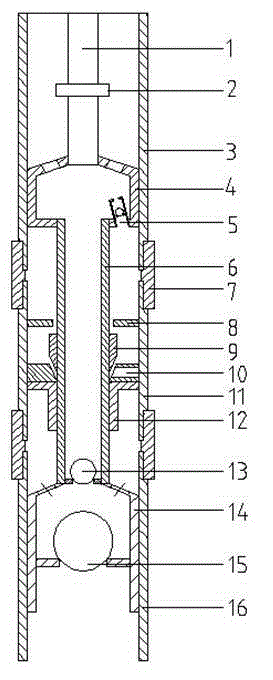

[0014] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0015] according to figure 1 As shown, a parallel double-chamber oil well pump, the upper part of the disconnector 2 is connected with the sucker rod 1, the upper part of the small plunger 6 is connected with the upper plunger 4, the lower part is connected with the lower plunger 14, and the outer pipe 11 is respectively connected with the upper pump The barrel 3 and the lower pump barrel 16 are connected by a collar 7, the upper plunger 4 and the upper liquid outlet 5 are in the upper pump barrel 3, the small plunger 6, the small pump barrel 12, the retaining ring 8, the slide valve 9 and the upper liquid inlet The port 10 is in the outer tube 11 , the upper traveling valve 13 , the lower plunger 14 and the lower tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com