Automatic online detection method for defects on upper and lower surfaces during steel plate pretreatment process

An automatic detection and preprocessing technology, applied in image data processing, optical testing flaws/defects, measuring devices, etc., can solve problems such as unavoidable missed detection, low efficiency, and insecurity, and achieve work safety, improve production efficiency, Detect accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

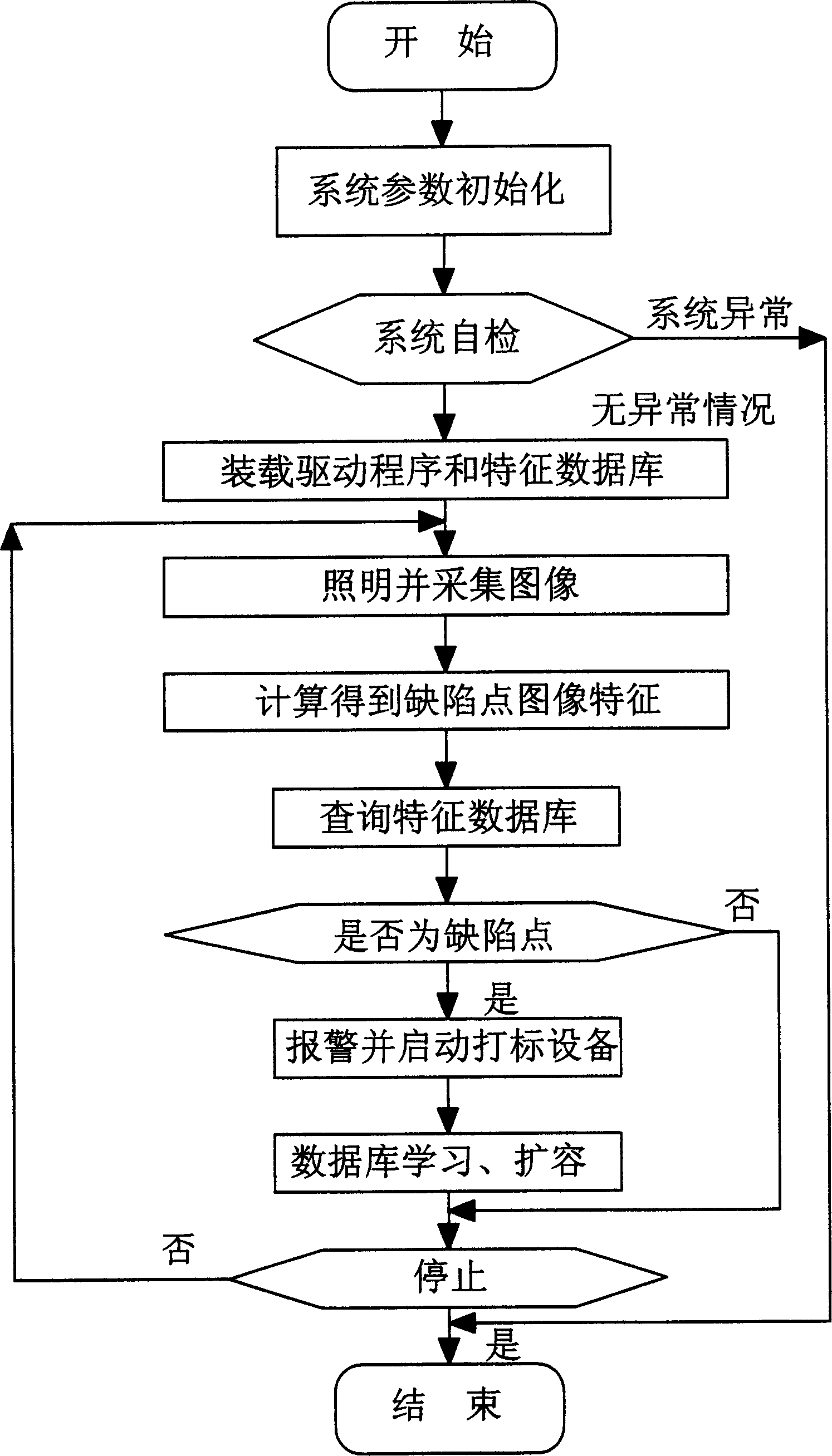

[0020] An online automatic detection method for upper and lower surface defects in the steel plate pretreatment process. This method uses high-speed imaging technology. According to the characteristics of the imaging color and gray level of defect points that are different from other normal points, the image chromaticity and gray level features are used. The identification technology identifies and classifies the defect points, and then inputs the images into the microcomputer for processing.

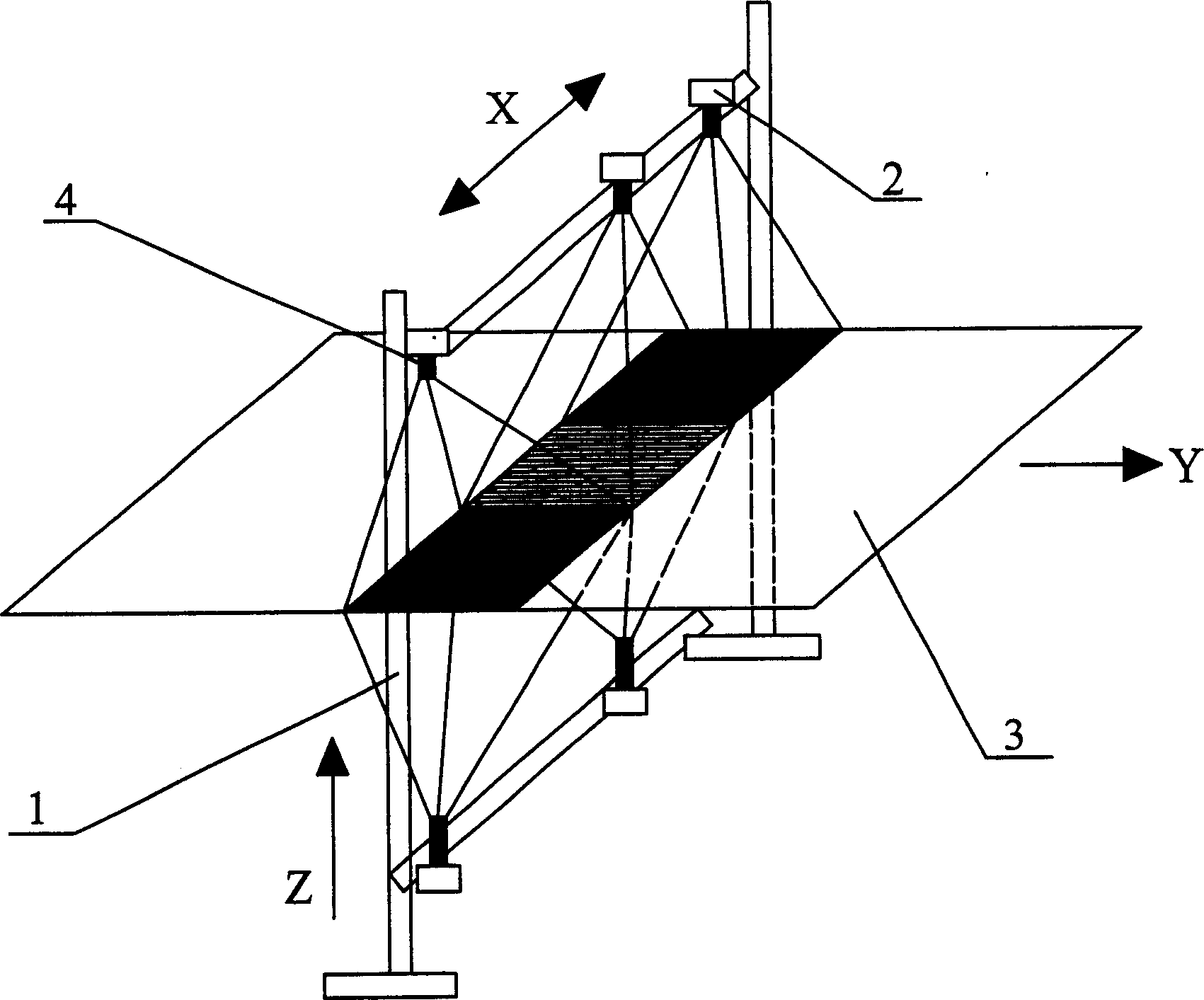

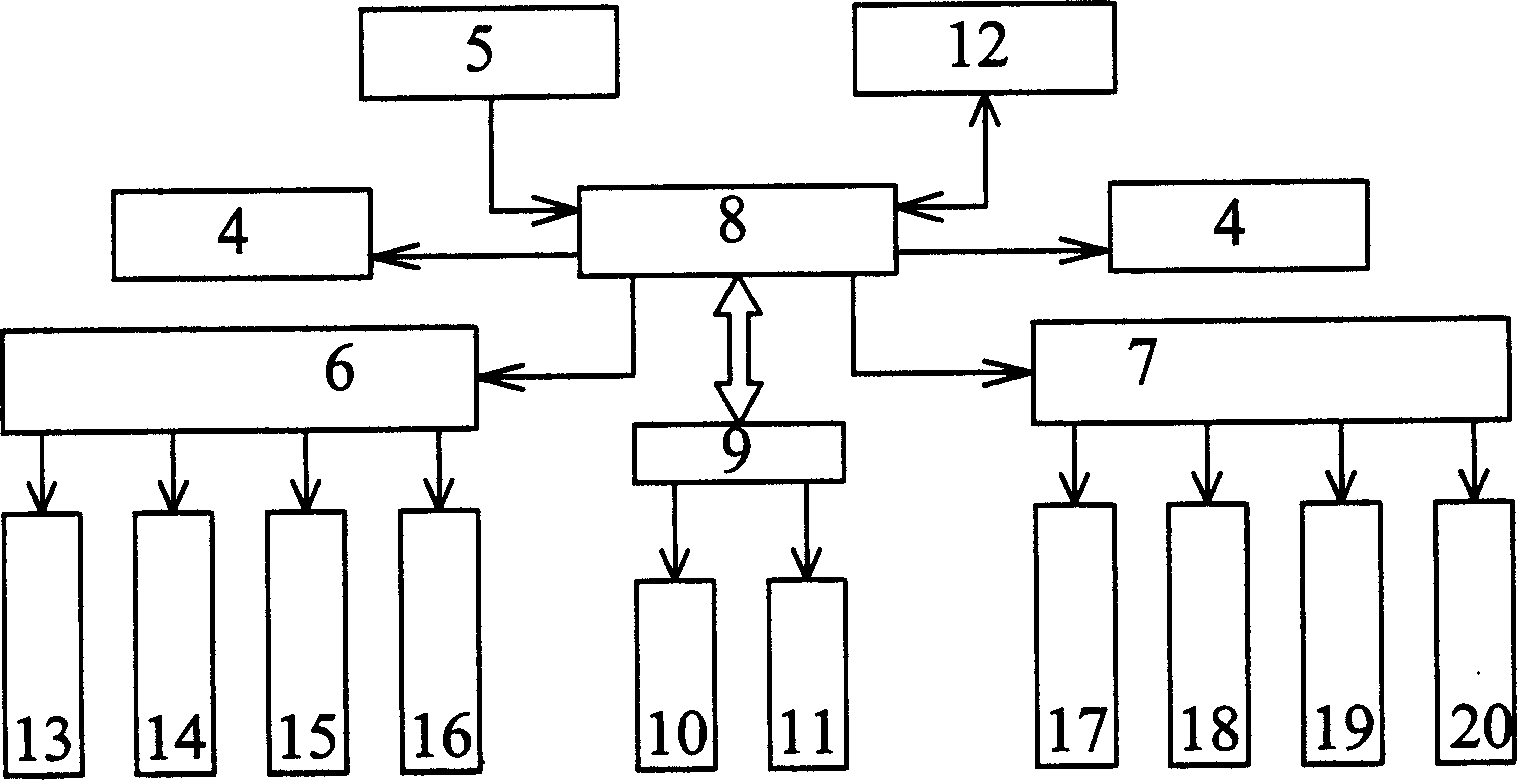

[0021] On-line automatic detection method for surface defects in steel plate pretreatment process, such as figure 1 , figure 2 shown. The detection system adopts a gantry structure. The gantry 1 is erected on the steel plate pretreatment line, and the steel plate 3 moves through the gantry 1 at a certain speed along the Y axis. The upper and lower beams of the gantry 1 are equipped with lighting facilities 4. The lighting facilities 4 mainly include a high-speed stroboscopic special ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com