Device for floating production of lng and method for converting a lng-carrier to such a device

A technology for transport ships and production systems, applied in the direction of transportation and packaging, installation devices for container construction, ship construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

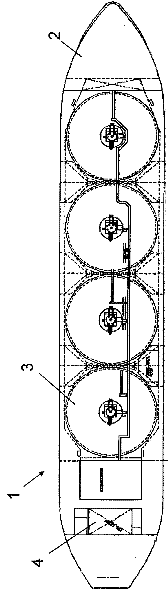

[0034] FIG. 1 illustrates the general arrangement of a typical Moss-type LNG carrier 1 . The LNG carrier 1 is used to store LNG. The LNG carrier 1 basically includes a hull 2 in which a spherical LNG storage tank 3 is arranged. The LNG carrier 1 is well known to those skilled in the art and will not be described in detail here. In the specific embodiment shown in FIG. 1 , the LNG carrier 1 includes four spherical LNG storage tanks 3 .

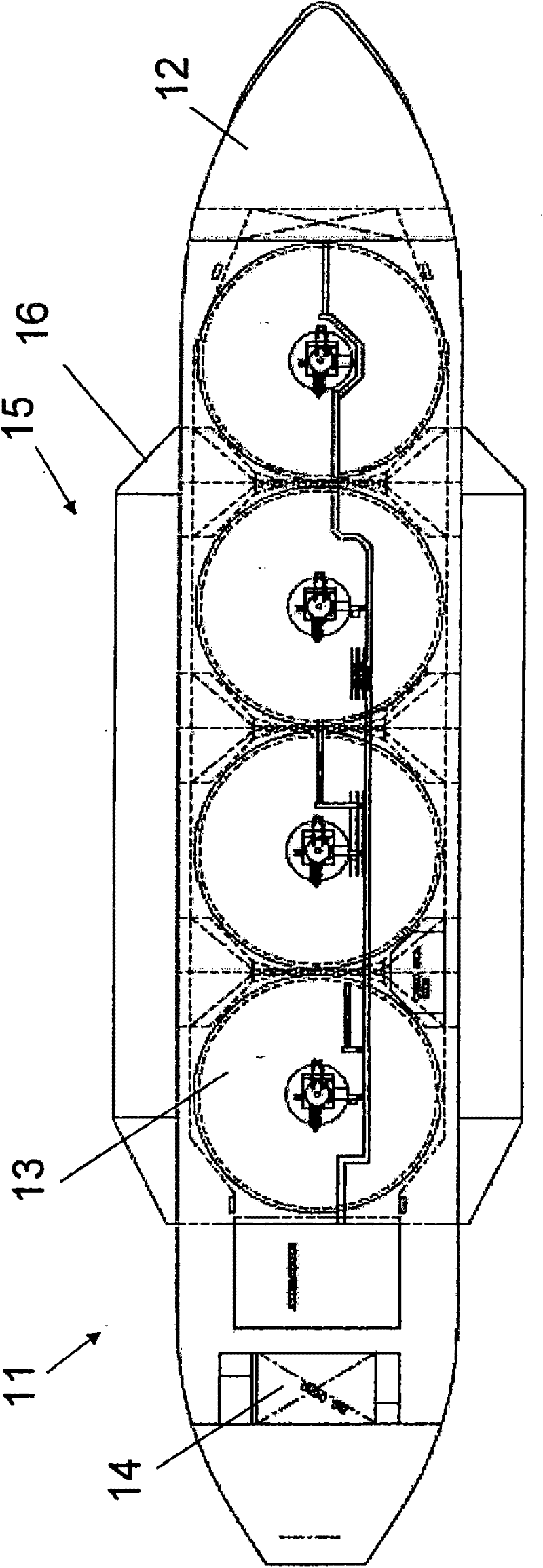

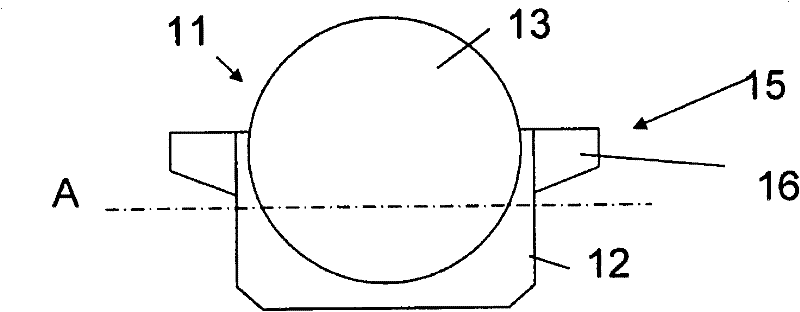

[0035] reference now figure 2 , figure 2 The present invention is illustrated as an apparatus 11 for suspension production of LNG (ie FLNG). As shown in FIG. 1 , the apparatus includes an LNG carrier 1 including a hull 12 and at least one spherical LNG storage tank 13 for storing LNG.

[0036] The device 11 can be utilized as a substantially stationary suspension unit anchored to the seabed or secured by the DP; natural gas is converted to LNG on the device 11 and the tank 13 is used for interim storage. In this way, LNG is delivered to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com