Refuse on water surface and cleaning ship for phytoplankton

A technology for phytoplankton and water surface garbage, which is used in the cleaning of open water surfaces, water conservancy projects, special-purpose ships, etc., which can solve the problems of water plants being easily entangled with knives, high cost, and difficult synchronization of actions, and achieve the effect of avoiding aquatic plants entangling knives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

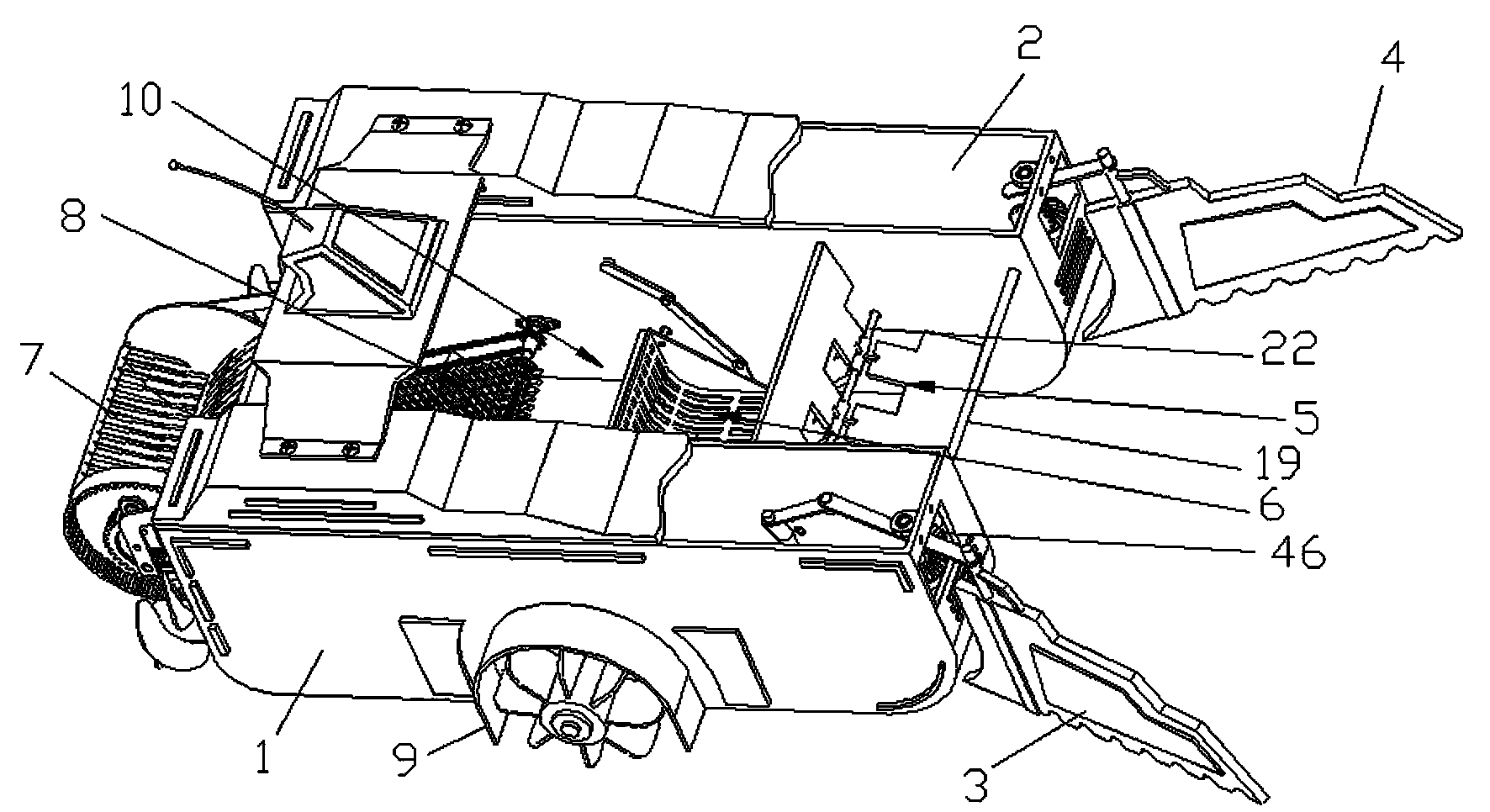

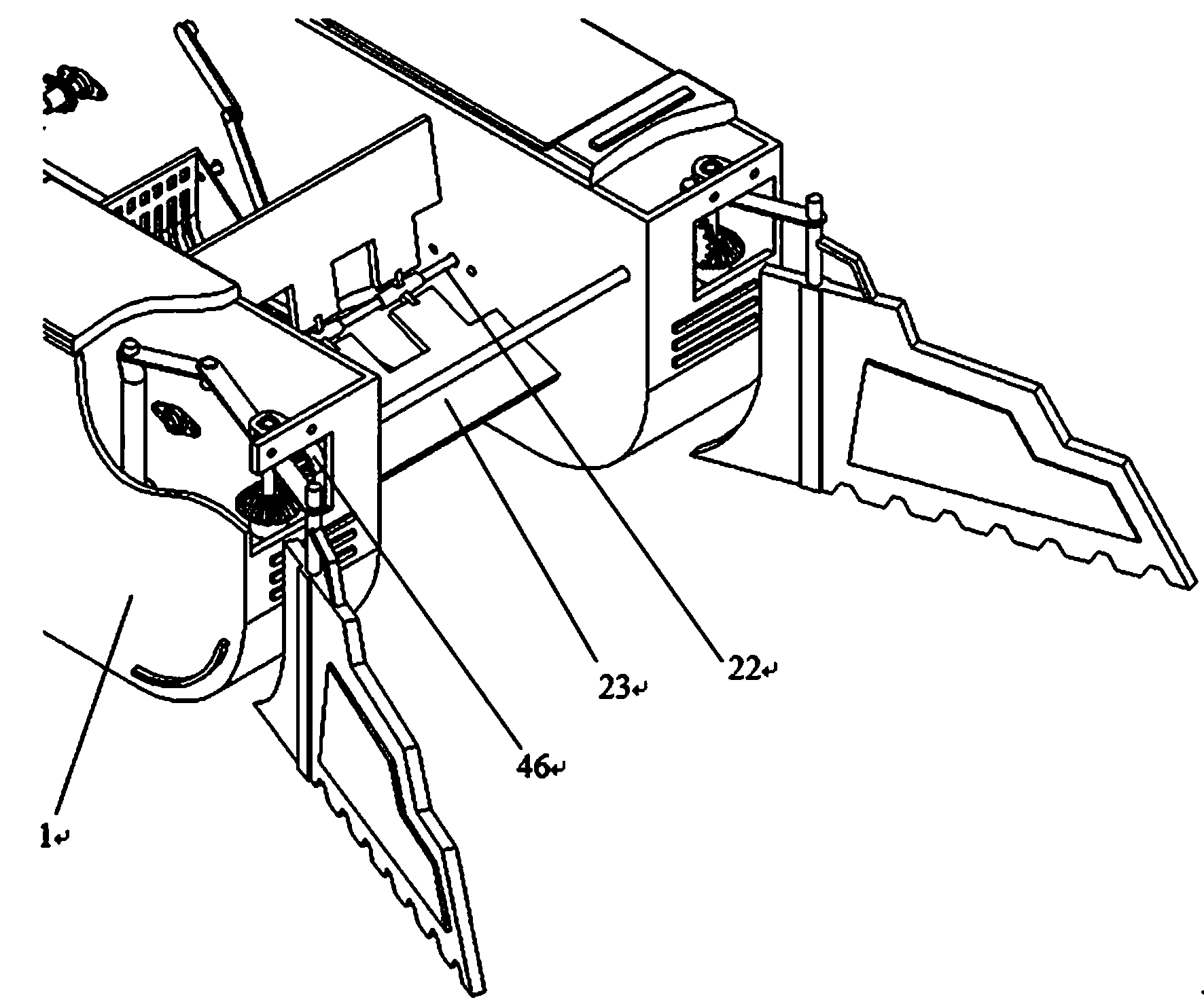

[0027] A water surface garbage and phytoplankton cleaning ship, comprising a left hull 1, a right hull 2, a left garbage guiding mechanism 3, a right garbage guiding mechanism 4, an impeller water guiding mechanism 5, a garbage tipping mechanism 6, and an aquatic plant cutting mechanism 7 , aquatic weed collection mechanism 8, two driving wheels 9 and garbage bin 10. The left hull 1 and the right hull 2 are connected as a whole.

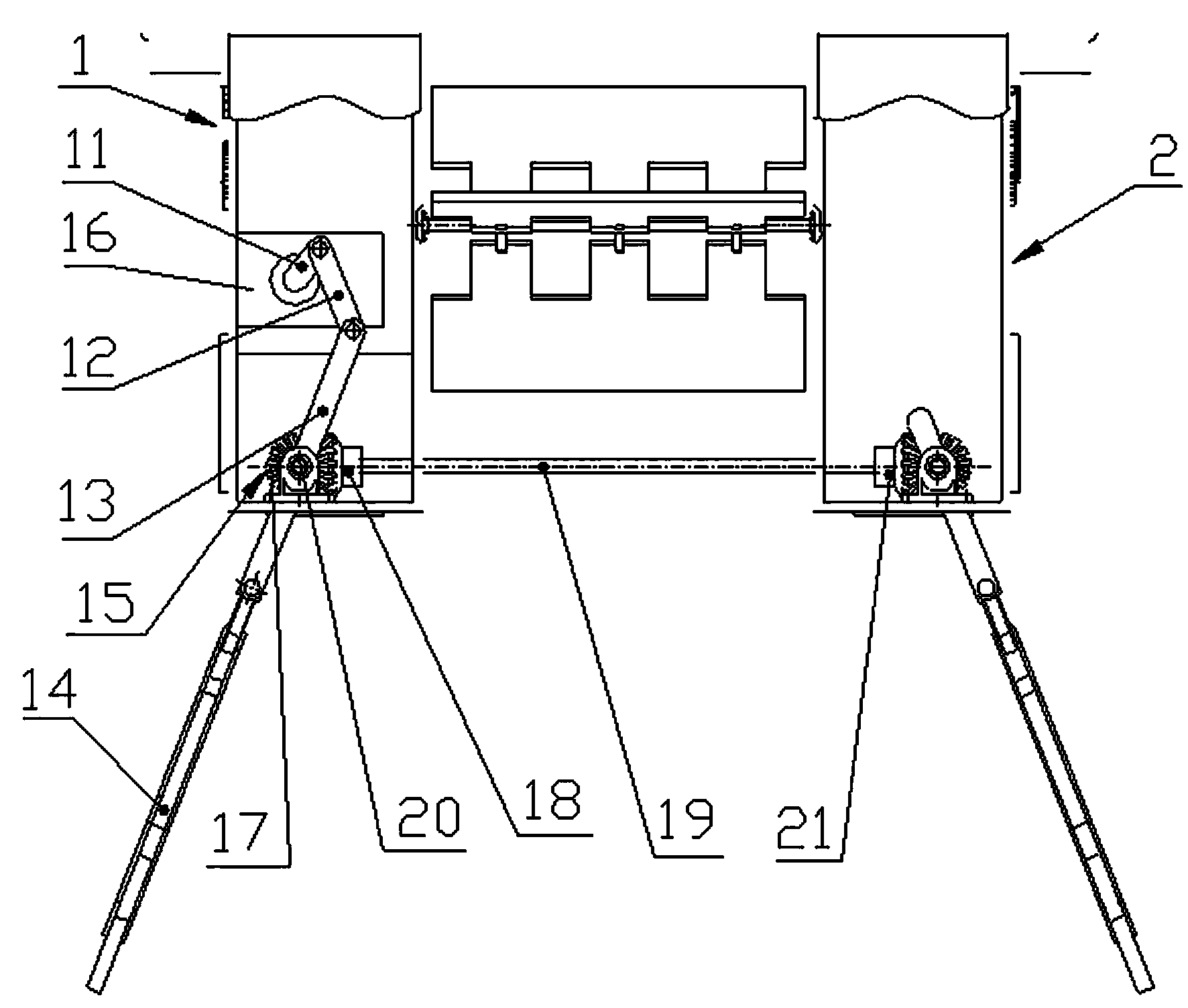

[0028] Left side garbage guiding mechanism 3 is installed in the bow position of left side hull 1, and left side garbage guiding mechanism 3 comprises crank 11, connecting rod 12, rocking bar 13, left side guide plate 14 and left side bevel gear transmission mechanism 15. The crank 11 is installed in the shaft hole on the ship plate 16 of the left side hull 1, the lower end of the crank 11 is connected with the output shaft of the motor installed in the left side hull 1, and the upper end of the crank 11 is hinged with one end of the connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com