Drilling integrated tool of double-tapered angle laminated structure with variable spiral groove

A stacked structure and variable helix technology, which is applied in the direction of manufacturing tools, other manufacturing equipment/tools, drilling accessories, etc., can solve the problems of poor chip removal, easy tool breakage, and difficult processing, etc., to ensure accuracy and Coaxiality, avoiding the phenomenon of knife wrapping, and improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

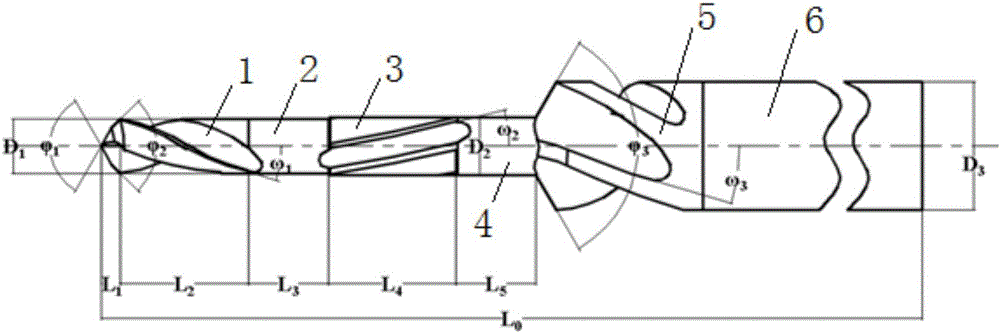

[0024] The integrated tool for making holes with variable spiral groove and double cone angle laminated structure is made of cemented carbide, and its structure is as figure 1 As shown, it includes a drilling portion 1, a first transition portion 2, a reaming portion 3, a second transition portion 4, a countersink portion 5, and a tool holder 6 connected in sequence. A first transition portion 2 is provided between the drilling portion 1 and the reaming portion 3, and a second transition portion 4 is provided between the reaming portion 3 and the countersink portion 5. The length L3 of the first transition portion 2 and the length L5 of the second transition portion 4 are 4 mm to 6 mm, which not only ensures the rigidity of the tool, but also leaves a sufficient retraction margin for tool manufacturing. The diameter of the handle 6 is D3.

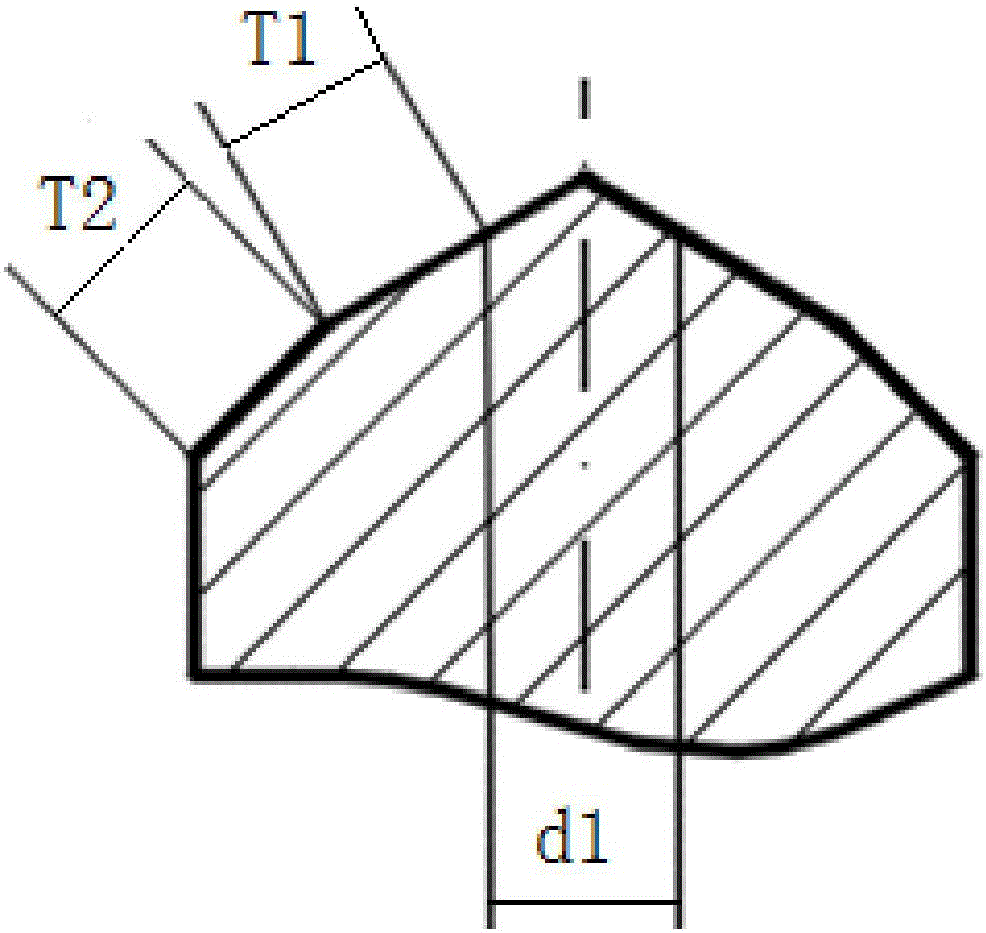

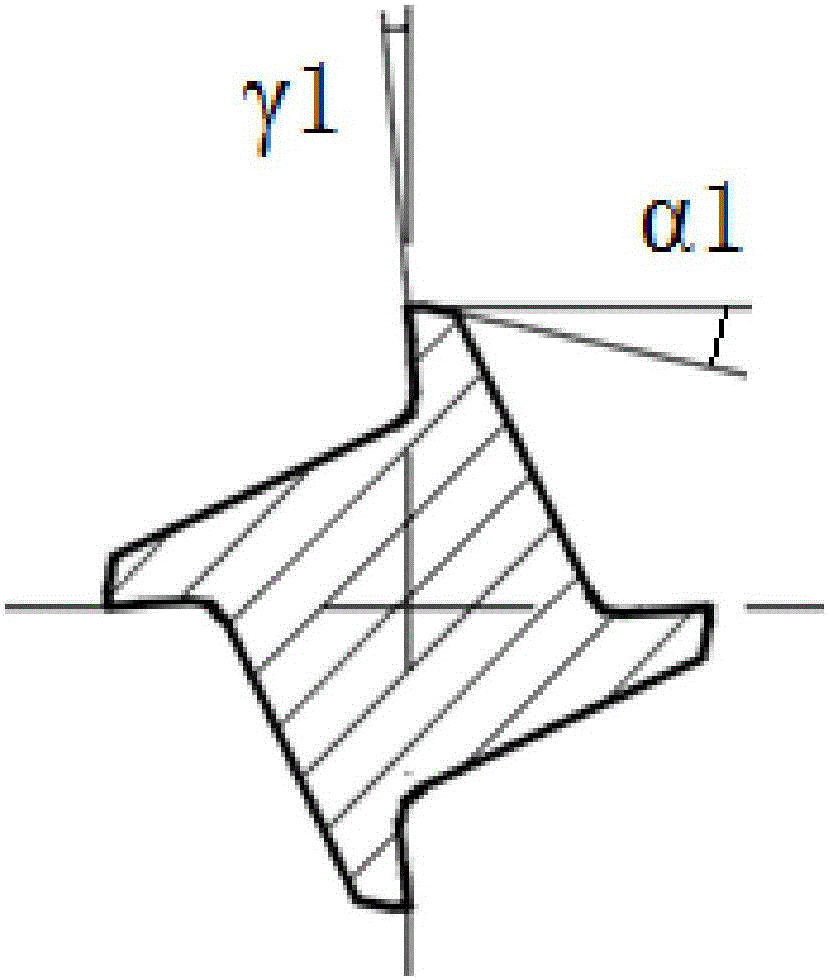

[0025] The drilling part 1 includes a double cone angle drill point and a spiral groove. The diameter of the drilling part 1 is D1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com