Nitrogen-charging fresh-keeping method for edible oil

A fresh-keeping method and edible oil technology, applied in the preservation of edible oil/fat products, edible oil/fat, application, etc., can solve problems such as hidden safety hazards, and achieve the effect of avoiding hidden dangers and preventing oil oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

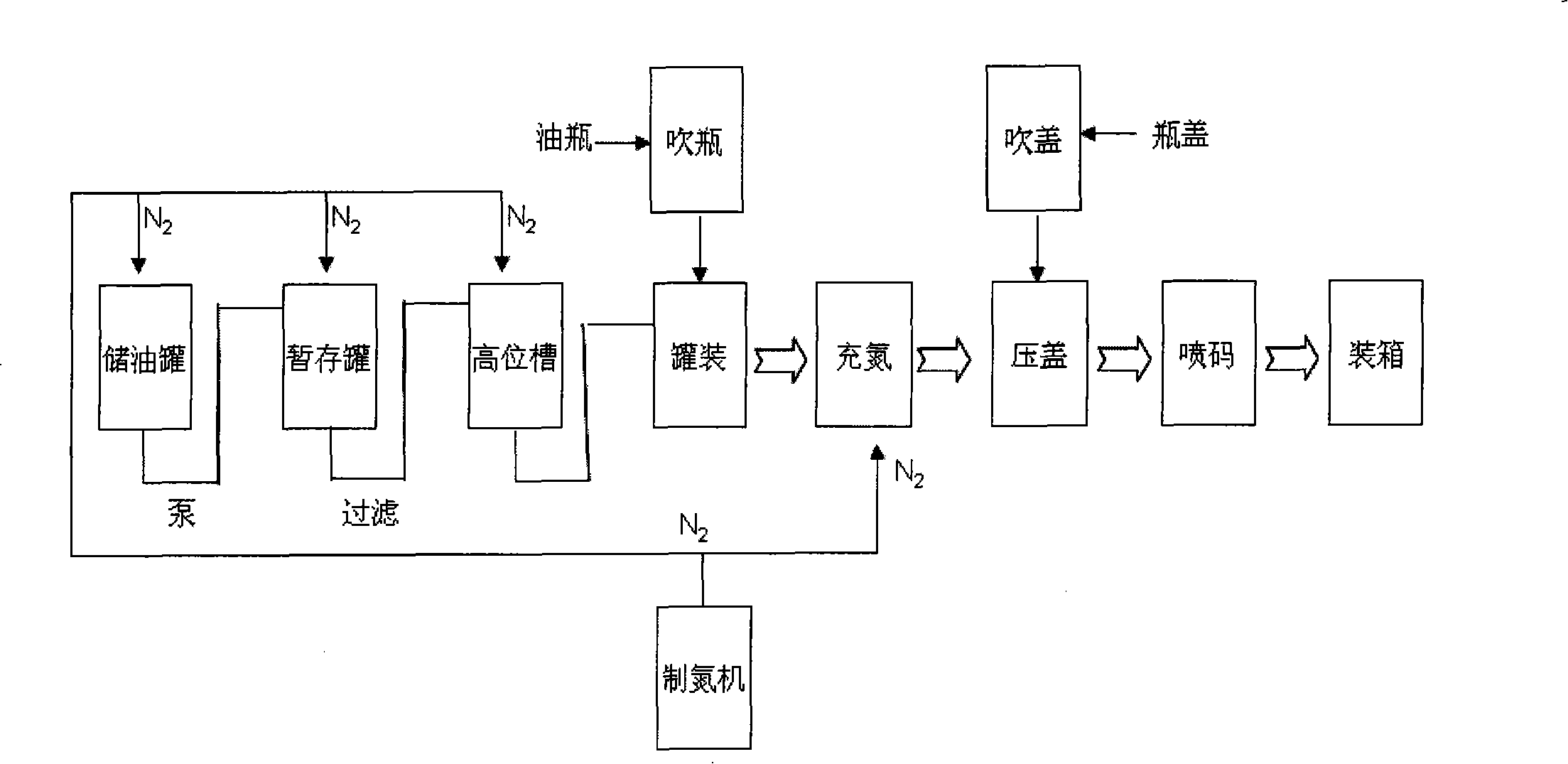

[0016] according to figure 1 As shown, the used oil storage tank and temporary storage tank are 200 tons and 100 tons, respectively, and can withstand positive pressure of 0.1Kg / cm 2 and 0.05Kg / cm 2 , can withstand negative pressure of 0.03Kg / cm 2 and 0.02Kg / cm 2 , the initial relief pressure set by the breathing valve is 0.0014kg / cm 2 , the starting suction pressure is 0.0014kg / cm 2 . The flow rate is 16m 3 / hr. From the self-filling nitrogen oil storage tank, use a pump to pump 50T sunflower seed primary oil into a temporary storage tank filled with nitrogen. After being filtered by a filter with a pore size of 5 μm, it is pumped into a high-level tank filled with nitrogen; the 5L oil bottle enters the canning system after being blown out of impurities, and is quantitatively filled by an automatic canning machine before entering the nitrogen filling system; Taken by machine, nitrogen with a purity of 99.9% is filled into the quantitatively filled oil bottle through t...

Embodiment 2

[0018] according to figure 1 As shown, the used oil storage tank and temporary storage tank are 200 tons and 100 tons, respectively, and can withstand positive pressure of 0.1Kg / cm 2 and 0.05Kg / cm 2 , can withstand negative pressure of 0.03Kg / cm 2 and 0.02Kg / cm 2 , the initial relief pressure set by the breathing valve is 0.0014kg / cm 2 , the starting suction pressure is 0.0014kg / cm 2 . The flow rate is 16m 3 / hr. Pump 50T canola oil from the nitrogen-filled oil storage tank into a temporary storage tank filled with nitrogen. After being filtered by a filter with a pore size of 5 μm, it is pumped into a high-level tank filled with nitrogen; the 2.5L oil bottle enters the canning system after being blown out of impurities, and enters the nitrogen filling system after being quantitatively filled by an automatic canning machine; It is produced by a nitrogen machine, and the nitrogen gas with a purity of 99.9% is filled into the quantitatively filled oil bottle through the ...

Embodiment 3

[0020] according to figure 1 As shown, the used oil storage tank and temporary storage tank are 200 tons and 100 tons, respectively, and can withstand positive pressure of 0.1Kg / cm 2 and 0.05Kg / cm 2 , can withstand negative pressure of 0.03Kg / cm 2 and 0.02Kg / cm 2 , the initial relief pressure set by the breathing valve is 0.0014kg / cm 2 , the starting suction pressure is 0.0014kg / cm 2 . The flow rate is 16m 3 / hr. From the self-filling nitrogen oil storage tank, use a pump to pump 50T sunflower seed primary oil into a temporary storage tank filled with nitrogen. After being filtered by a filter with a pore size of 5 μm, it is pumped into a high-level tank filled with nitrogen; the 1.8L oil bottle enters the canning system after being blown out of impurities, and is quantitatively filled by an automatic canning machine before entering the nitrogen filling system; It is produced by a nitrogen machine, and the nitrogen gas with a purity of 99.9% is filled into the quantita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com