Combustion type gas heat value measuring method and heat value meter thereof

A gas calorific value and gas technology, which is used in measuring devices, fuel oil testing, instruments, etc., can solve the problems of poor measurement accuracy, high price, poor operation stability, etc., and achieves low maintenance workload, high result accuracy, and high sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

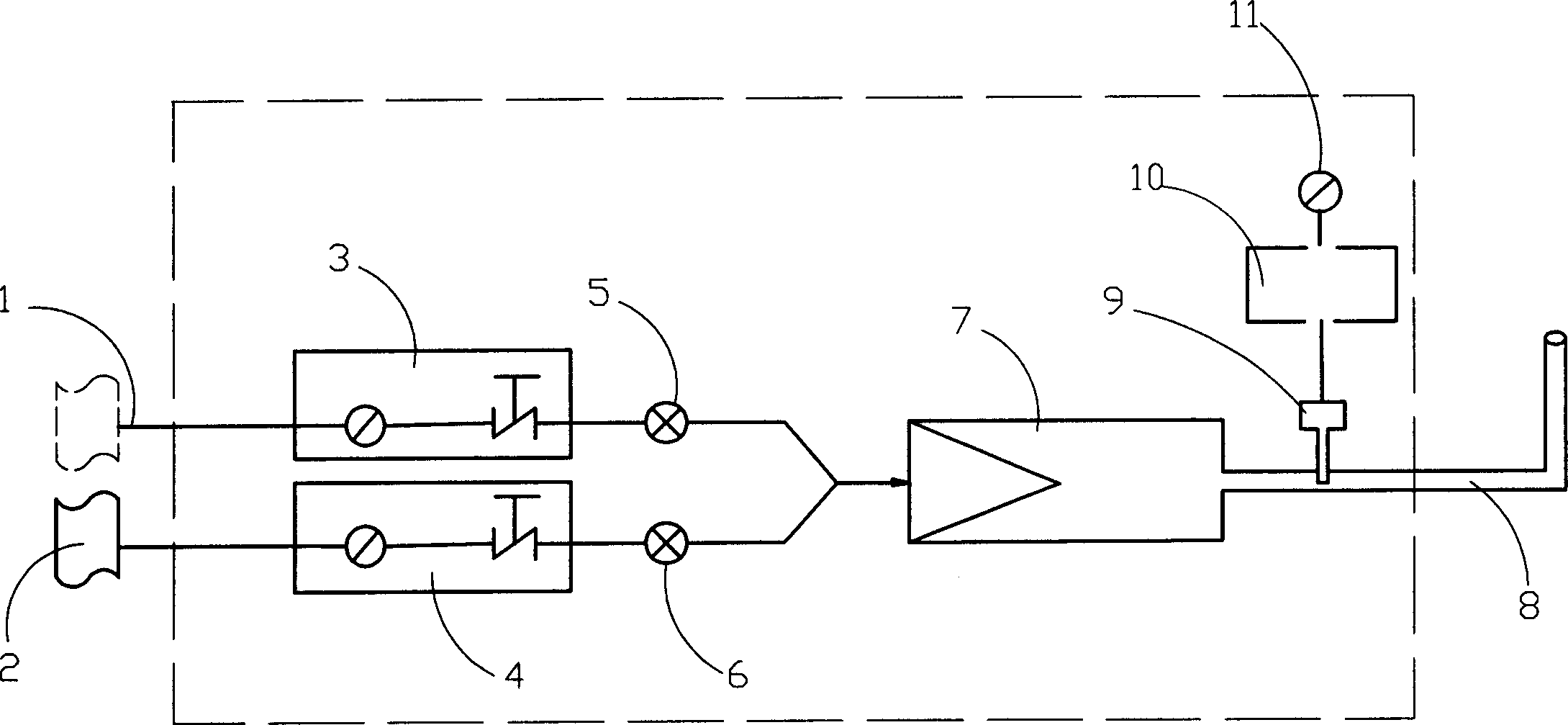

[0014] As shown in the figure, the method for measuring the calorific value of combustion-type gas involved in the present invention uses a gas connection device 1 and a combustion-supporting air delivery device 2 to input a certain amount of gas and a certain amount of combustion-supporting air into the combustion furnace barrel 7 for complete combustion. Flue gas, the calorific value of the gas is calculated by measuring the residual oxygen content in the flue gas produced by complete combustion in the furnace cylinder.

[0015] In the embodiment of the calorific value meter for measuring the calorific value of combustion gas involved in the present invention, it includes a gas connection device 1, a combustion air delivery device 2, a gas treatment device 3, a combustion air treatment device 4, a gas flow detection device 5, a combustion Air flow detection device 6, combustion furnace tube 7 and smoke exhaust device 8, one end of the gas connection device 1 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com