System and method for automatically controlling content of residual oxygen in regenerative heating furnace

An automatic control system and technology of residual oxygen content, applied in combustion methods, control of combustion, lighting and heating equipment, etc., can solve the problems of large lag in temperature control system, large fluctuation of gas calorific value and unsatisfactory actual effect, etc. The effect of reducing pollution, reducing oxidative burning loss and air pollution, and reducing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

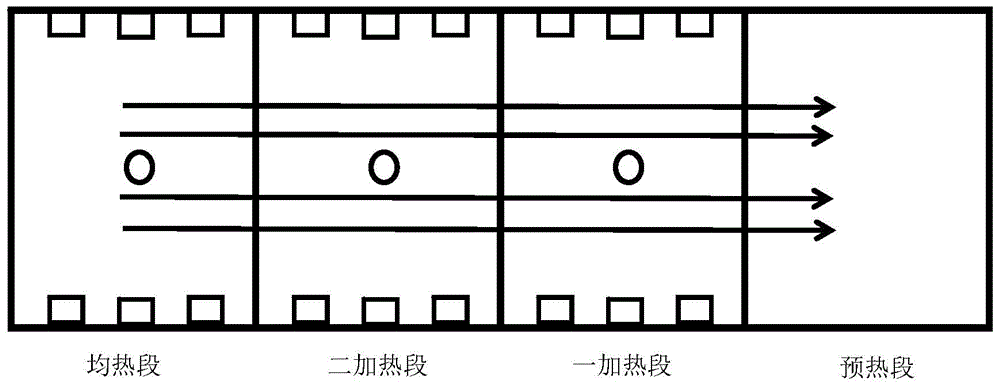

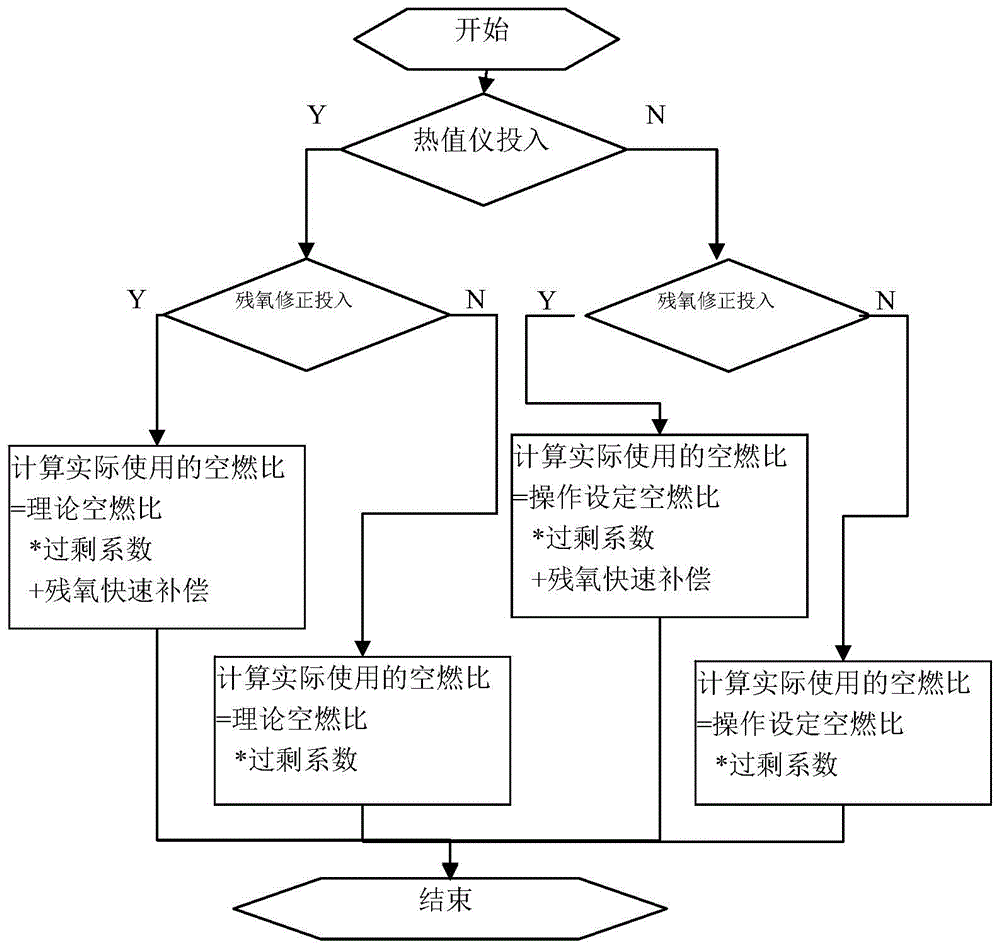

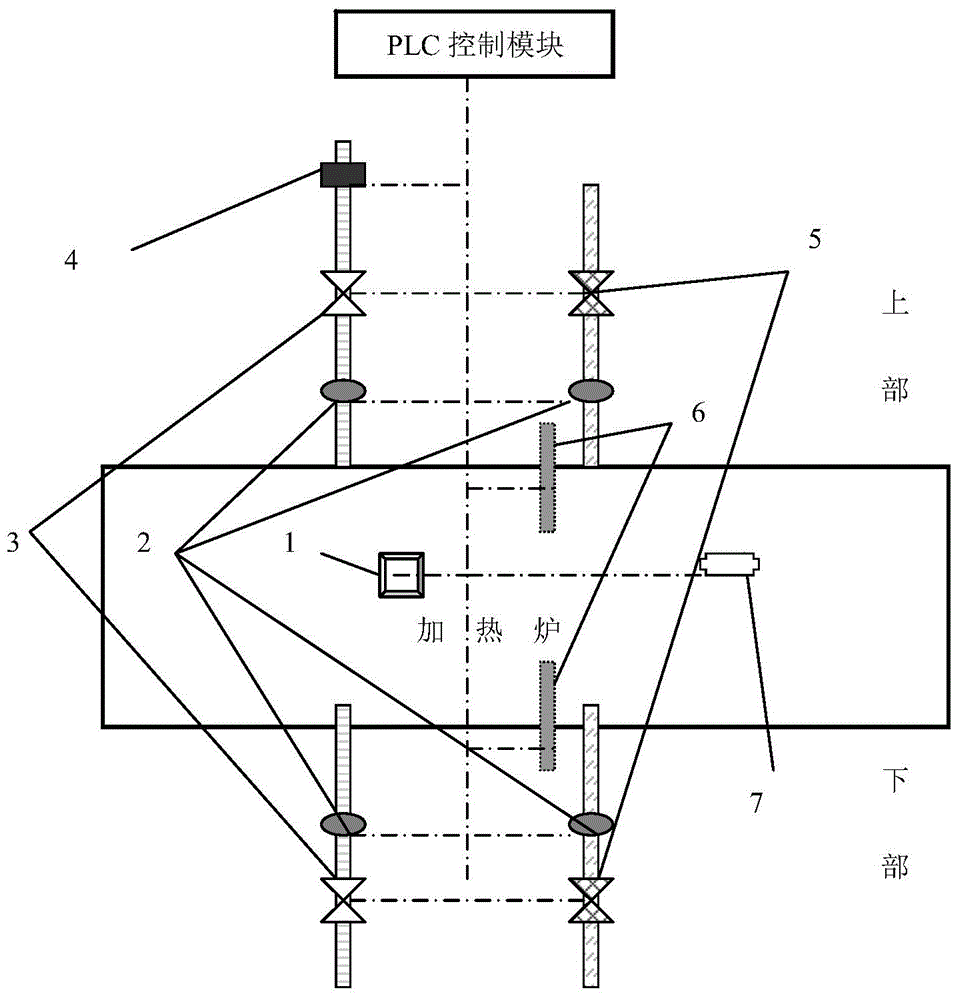

[0026] A set of automatic control method applied to the residual oxygen content in the heating furnace furnace proposed by the present invention adopts the theoretical air-fuel ratio and zirconia analyzer to realize the automatic correction of the actual air-fuel ratio. A specific heating furnace is used as an example below , detailing the process of controlling the residual oxygen content in the furnace. What present embodiment selects for use is the heating furnace of regenerative type, stepping, mixed gas combustion. The heating furnace uses high-temperature and coke mixed gas as fuel, its normal calorific value: 9630kj / m3, and the ratio value of the reference air-fuel ratio is 2.33:1 (air volume: gas volume). The heating furnace is divided into 3 heating sections, and each heating section is divided into upper and lower parts, including the upper part of the first heating part, the lower part of the first heating part, the upper part of the second heating part, the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com