Catalyst with methane catalytic combustion and conversion functions and preparation method thereof

A methane catalytic combustion, dual-function catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of raw gas combustion heat retention and large heat release , environmental dust and other problems, to achieve the effect of reducing equipment size, reducing gas volume, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

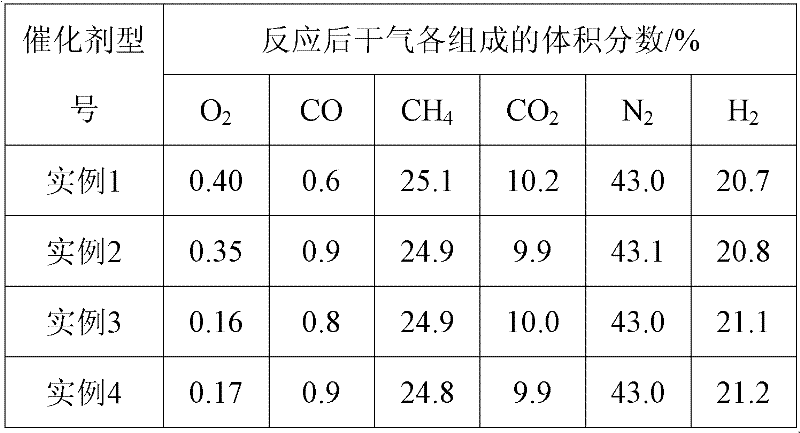

Embodiment 1

[0023] The low-quality coalbed methane catalytic combustion and catalytic conversion dual-function catalyst in this embodiment mainly includes a carrier, active components and additives, in which:

[0024] Take Al 2 o 3 and SiO 2 The mixed material is the raw material, ball milled, shaped and calcined to obtain the integral catalyst carrier, the active components are nickel and manganese (both exist in the catalyst in the form of oxides), and magnesium oxide is used as an auxiliary agent: the mass fraction of the carrier is 94 %, the mass fraction of active components nickel oxide and manganese dioxide is 5%, and the content of magnesium oxide is 1%. In this embodiment, the low-quality coalbed gas catalytic combustion and catalytic conversion dual-function catalyst is prepared by the method of the following main steps:

[0025] (1), high-temperature calcination is obtained carrier: the Al of industrial raw material 2 o 3 and SiO 2 (Al 2 o 3 with SiO 2 The mass ratio i...

Embodiment 2

[0030] The low-quality coalbed methane catalytic combustion and catalytic conversion dual-function catalyst in this embodiment mainly includes a carrier, active components and additives, among which:

[0031] Take Al 2 o 3 The mixture of montmorillonite and montmorillonite is used as the raw material, and the integral catalyst carrier is obtained after molding and calcining. The active components are nickel and cobalt (both exist in the catalyst in the form of oxides), and MgO is used as the auxiliary agent: the mass fraction of the carrier The mass fraction of active components nickel oxide and cobalt oxide is 15%, and the mass fraction of magnesium oxide is 5%.

[0032] In this embodiment, the low-quality coalbed gas catalytic combustion and catalytic conversion dual-function catalyst is prepared by the method of the following main steps:

[0033] (1), high-temperature calcination is obtained carrier: the Al of industrial raw material 2 o 3 and montmorillonite (Al 2 o ...

Embodiment 3

[0040] The low-quality coalbed methane catalytic combustion and catalytic conversion dual-function catalyst in this embodiment mainly includes a carrier, active components and additives, among which:

[0041] Take Al 2 o 3 The mixture of kaolin and kaolin is used as raw material, and the integral catalyst carrier is obtained after molding and calcining. The active components are nickel and cobalt (both exist in the catalyst in the form of oxides), and BaO is used as an auxiliary agent: the carrier content is 70%. The mass fraction of the active components nickel oxide and cobalt oxide is 20%, and the mass fraction of barium oxide is 10%. In this embodiment, the low-quality coalbed gas catalytic combustion and catalytic conversion dual-function catalyst is prepared by the method of the following main steps:

[0042] (1), high-temperature calcination is obtained carrier: the Al of industrial raw material 2 o 3 and kaolin (Al 2 o 3 The mass ratio with kaolin is 1: 1.5) and mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com