Production method for light emitting element

a production method and light-emitting element technology, applied in the direction of polycrystalline material growth, crystal growth process, chemically reactive gas, etc., can solve the problems of increasing production costs, increasing production costs, and consuming a considerable amount of energy, so as to enhance the effect of introducing se or te, improving crystallinity of active layer, and enhancing binding tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

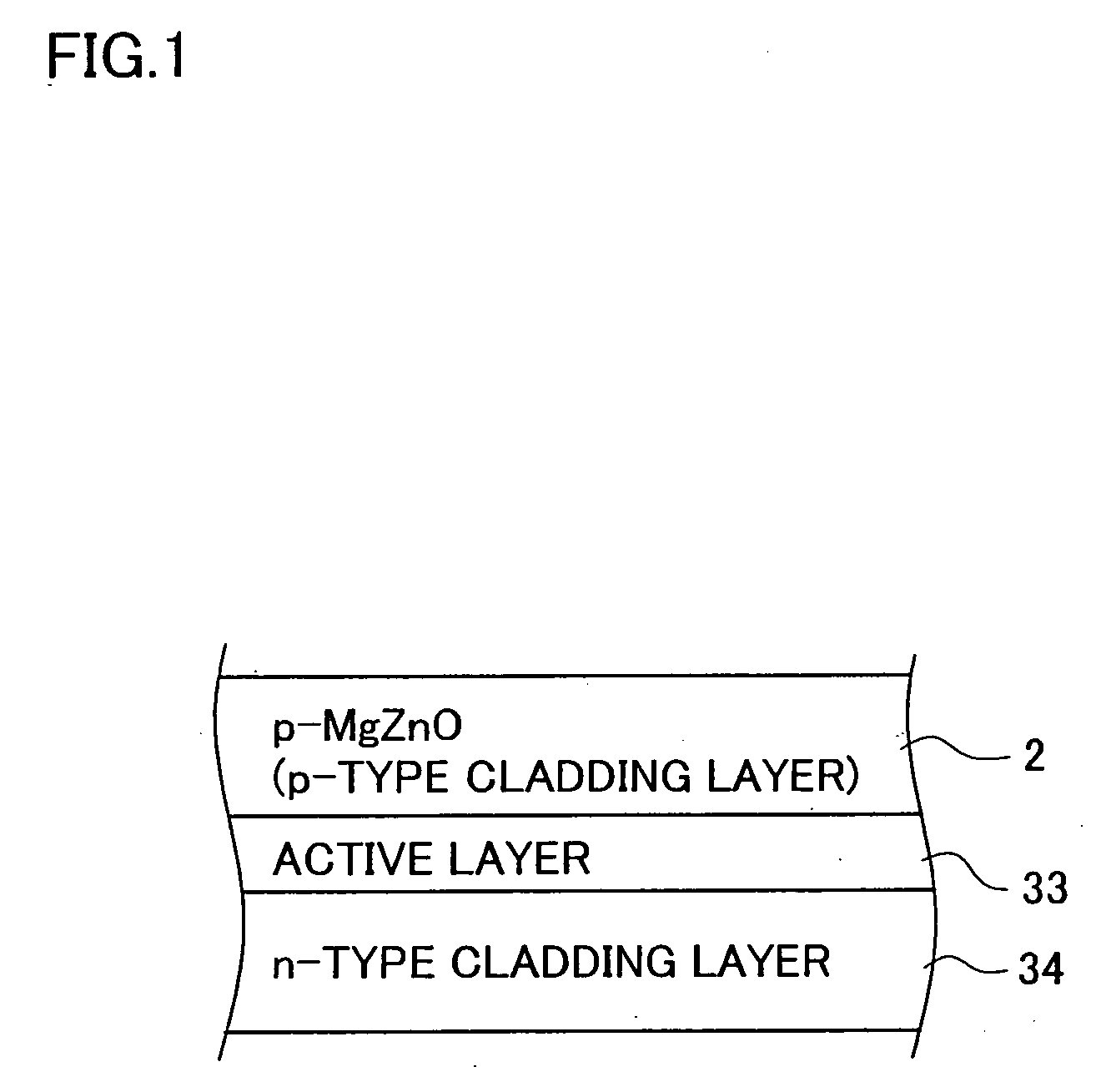

[0107]FIG. 1 is a drawing schematically showing a stacked structure of the essential portion of the light emitting device of the first invention, and the device has a light emitting layer portion in which an n-type cladding layer 34, an active layer 33 and a p-type cladding layer 2 are stacked in this order. The p-type cladding layer 2 is composed as a p-type MgxZn1-xO layer (0≦x≦1: may occasionally be referred to as p-type MgZnO layer 2, hereinafter). In the p-type MgZnO layer 2, a trace amount of either one of, or two or more of N, Ga, Al, In and Li, for example, are contained as a p-type dopant. The p-type carrier-concentration is adjusted within a range from 1×1016sites / cm3 to 8×1018 sites / cm3 as described in the above, and more specifically within a range from 1017 sites / cm3 to 1018 sites / cm3 or around.

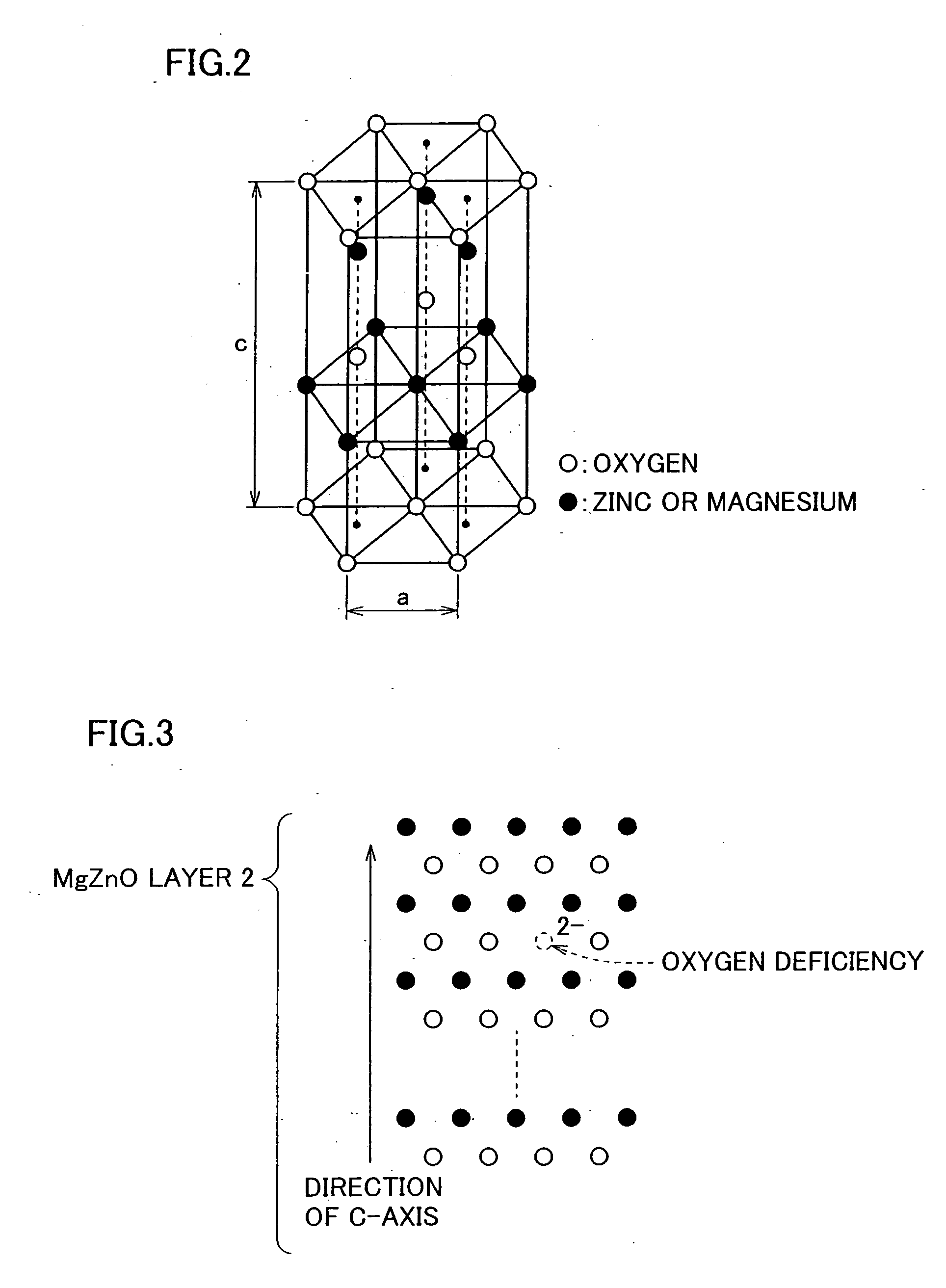

[0108]FIG. 2 is a schematic drawing of a crystal structure of MgZnO, where so-called wurtzite structure is shown. In this structure, oxygen-ion-packed planes and metal-ion (Zn i...

embodiment 2

[0150] The next paragraphs will describe an embodiment of the second invention. Since the essential portion of the light emitting device to which the second invention is applicable is same as described in Embodiment 1, detailed description will be omitted (see FIGS. 1 to 4, and FIGS. 10A and 10B). As shown in (a) of FIG. 6, the GaN buffer layer 11 is epitaxially grown again on the sapphire substrate 10, and further thereon the p-type MgZnO layer 52 (typically of 50 nm thick), the MgZnO active layer 53 (typically of 30 nm thick) and the n-type MgZnO layer 54 (typically of 50 nm thick) are formed in this order (inverted order of the growth also acceptable). The epitaxial growth of the individual layers in this embodiment can be carried out by the MOVPE process similarly to as described in Embodiment 1, where differences reside in the following points. More specifically, in the growth of the MgZnO active layer 53 and p-type MgZnO layer 52 herein, a ultraviolet lamp (e.g., excimer ultra...

embodiment 3

[0158] The next paragraphs will describe an embodiment of the third invention. Although the essential portion of the light emitting device to which the third invention is applicable is almost the same as described in Embodiment 1 (see FIGS. 1 to 5A, and FIGS. 10A and 10B), it is essential in the third invention to form the buffer layer as described below. That is, the buffer layer has the c-axis of the wurtzite crystal structure oriented to the thickness-wise direction, has a single metal atom layer as a metal monoatomic layer formed in contact with the substrate, and has the residual oxygen atom layers and metal atom layers alternatively stacked successive to the metal monoatomic layer. An exemplary fabrication process will be explained below.

[0159] First as shown in FIG. 13, a buffer layer 111 composed of MgZnO is epitaxially grown on the sapphire substrate 10, and further thereon an n-type MgZnO layer 34 (typically of 50 nm thick), an MgZnO active layer 33 (typically of 30 nm th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| band gap energy | aaaaa | aaaaa |

| band gap energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com