Chopstick spray-paint equipment and chopstick spray-paint method

A technology of spraying equipment and chopsticks, which is applied in the direction of spraying device, device for coating liquid on the surface, surface pretreatment, etc. It can solve the problems of low efficiency of painting process, large paint loss, waste of raw materials, etc., and save round-trip transportation and The effect of drying and placing the place, extensive practical significance and market value, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

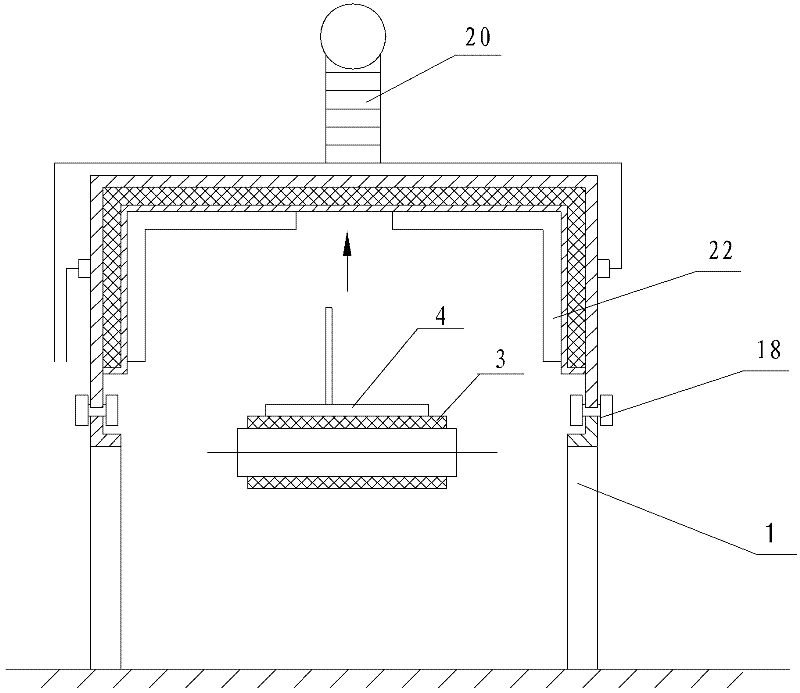

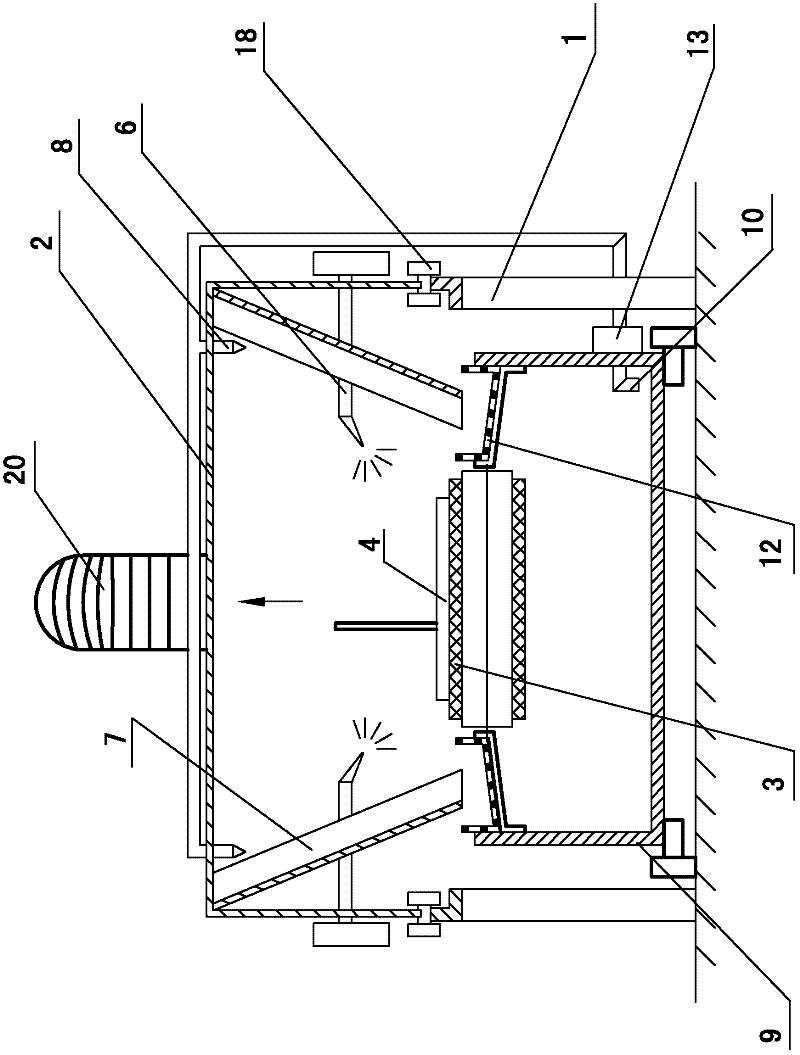

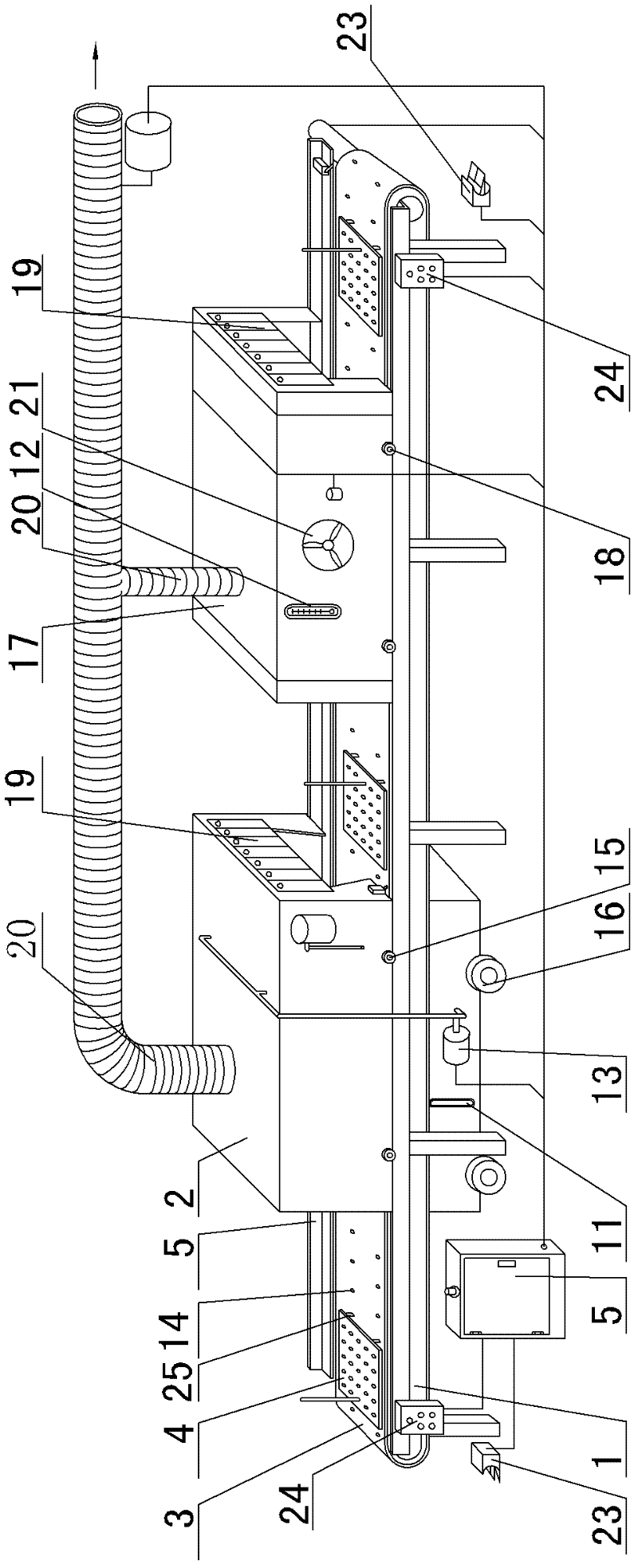

[0032] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0033] Refer to attached figure 1 , shown in accompanying drawing is a kind of chopsticks painting equipment provided by the present invention, described painting equipment comprises frame 1, paint spray box 2, conveyer belt 3, chopstick plate 4; Both sides of described frame are provided with guide rails in parallel, convey The belt 3 is installed on the frame 1, the paint spray box 2 is arranged on the guide rail of the frame 1, the conveyor belt 3 passes through the paint spray box 2, the conveyor belt 3 is provided with a chopstick plate 4, and the chopstick plate 4 is provided with inserts for fixing chopsticks. holes; the painting equipment is also provided with an electric control box 5 for electrical control of the painting equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com