Automatic device for paint spraying of wood door

A technology of automatic device and wooden door, applied in the direction of spraying device, etc., can solve the problems of physical exertion, low painting efficiency, physical health hazards, etc., and achieve the effect of reducing labor intensity, improving painting efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

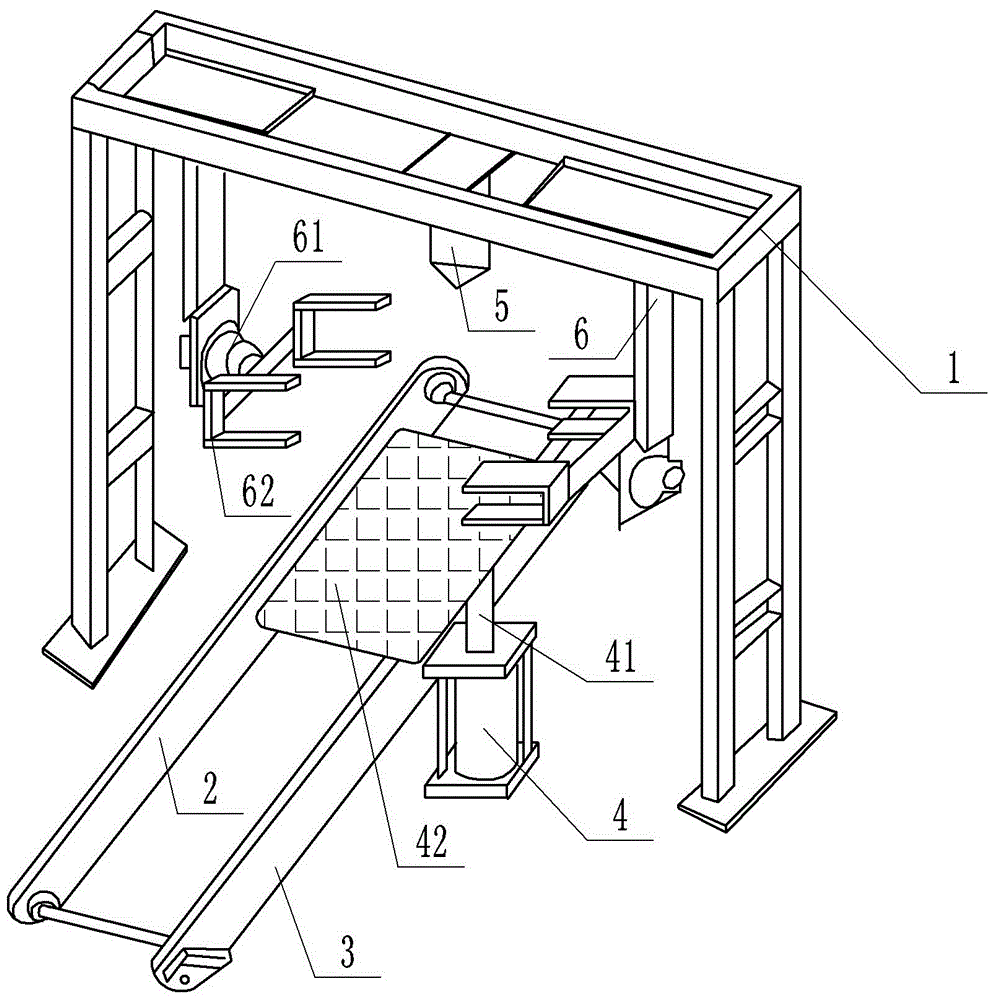

[0013] The reference signs in the accompanying drawings of the description include: bracket 1, left conveyor chain 2, right conveyor chain 3, hydraulic cylinder 4, piston rod 41, lifting table 42, automatic painting device 5, moving rod 6, servo motor 61, gripper 62.

[0014] Such as figure 1 As shown, the present invention includes a support 1, a conveying device, a lifting device, a clamping turning device and an automatic painting device 5, and the support 1 is located on one side of the conveying direction of the conveying device. The conveying device comprises a left conveying chain 2 and a right conveying chain 3, and wooden doors to be painted are placed on the left conveying chain 2 and the right conveying chain 3 and wait to be conveyed. The lifting device is located between the left conveyor chain 2 and the right conveyor chain 3. The lifting device includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com