Steel pipe paint brushing device for buildings

A technology for steel pipe brushing and construction, applied in the direction of spraying devices, etc., can solve the problems of pollution, uneven painting, time-consuming and laborious, and achieve the effect of avoiding environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

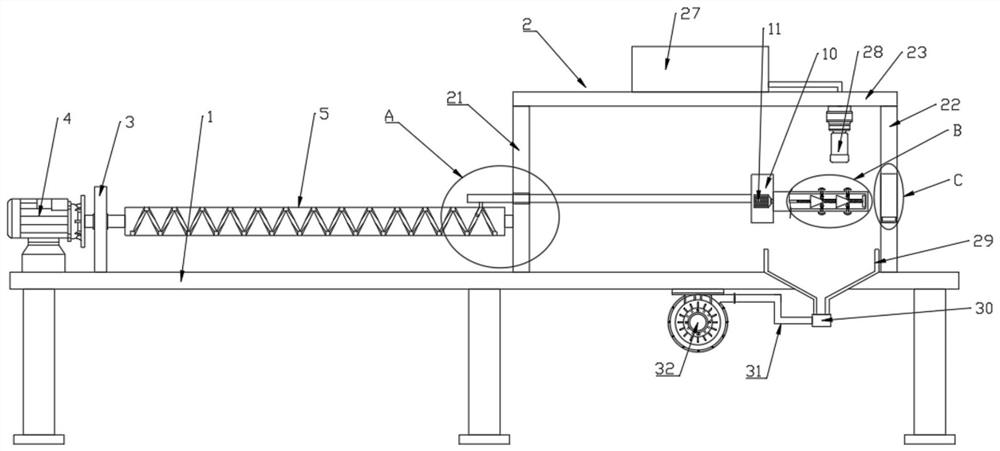

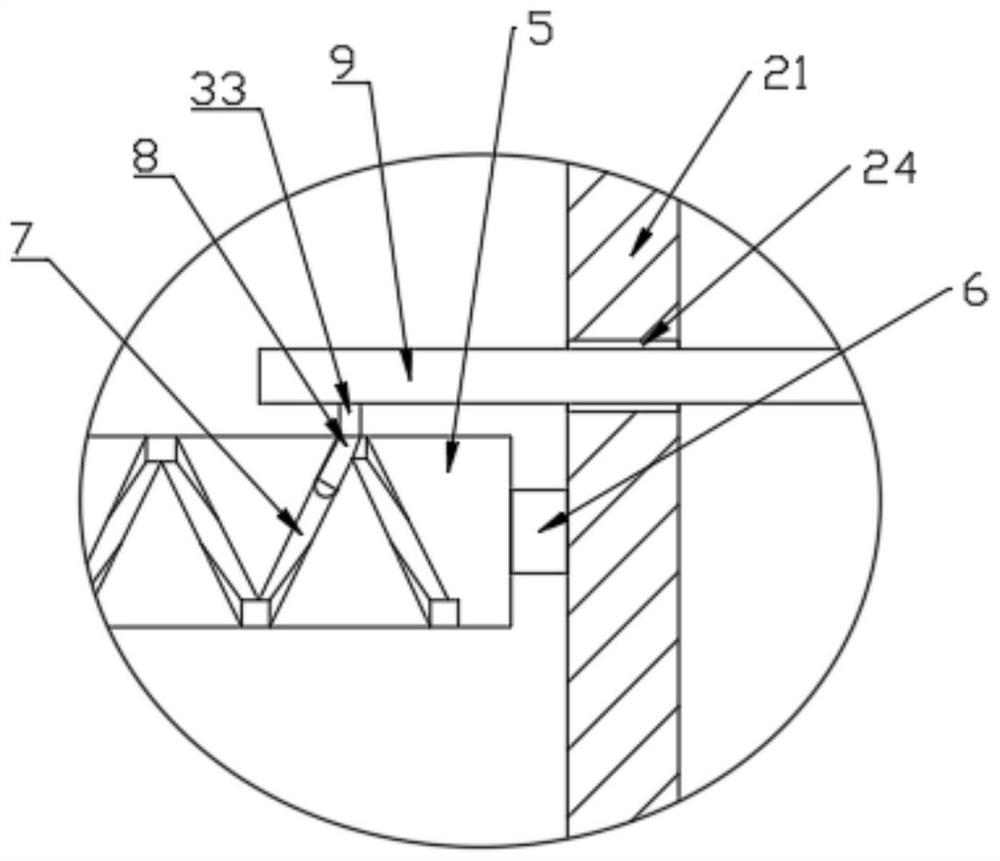

[0024] see Figure 1-5 , a steel pipe painting device for construction, including a workbench 1, a placing frame 2, a painting assembly 27, a clamping mechanism, and a driving mechanism for driving the clamping mechanism to reciprocate and rotate, and the placing frame 2 includes a left support plate 21. The right support plate 22 and the top plate 23 fixed on the top of the left support plate 21 and the right support plate 22, the left support plate 21 is provided with a rotation groove 24, and the right support plate 22 is provided with a placement groove 25. A plurality of rotating wheels 26 are arranged for rotation in the placement groove 25, and the clamping mechanism is located in the placement frame 2, and the driving mechanism includes a support base 3, a servo motor 4 and a transmission screw 5, and the support base 3 is fixedly located on the The top surface of the workbench 1, and the rotating shaft 6 is arranged between the support seat 3 and the placement frame 2...

Embodiment 2

[0027] This embodiment expands the functions on the basis of Embodiment 1, specifically:

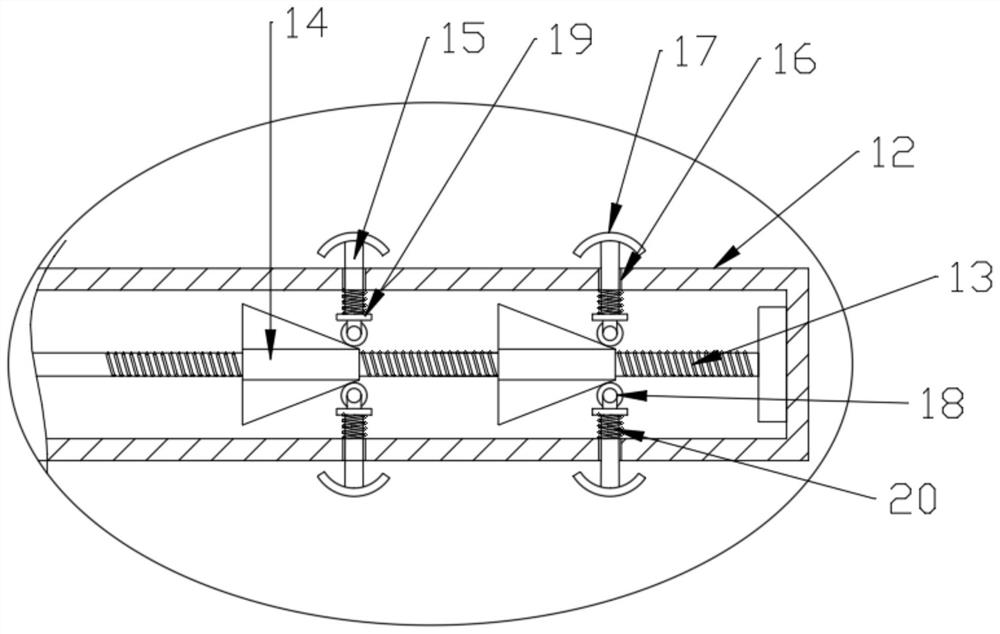

[0028] The clamping mechanism includes a driving motor 11, a supporting horizontal tube 12, a rotating screw 13, a moving block 14 and a push rod 15. The supporting horizontal tube 12 is fixedly connected with the turntable 10, and the axis of the supporting horizontal tube 12 is connected with the transmission The axis centers of the lead screw 5 are parallel, the rotating lead screw 13 is installed in the support horizontal tube 12, and the rotating lead screw 13 is driven by the drive motor 11 provided in the turntable 10, and the rotating lead screw 13 is located in the support horizontal tube The rod body of 12 is provided with a moving block 14 threaded with it, and a plurality of through holes 16 are provided on the support horizontal tube 12, and the push rod 15 is slidably connected with the through holes 16, and the push rod 15 is positioned on the support horizontal tube 12. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com