Intelligent manufacturing and painting device for new energy automobile parts

A new energy vehicle and intelligent manufacturing technology, applied in the field of auto parts processing, can solve the problems of easy shaking or misalignment of the workpiece, large volume, difficult painting operation on the surface of the workpiece, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

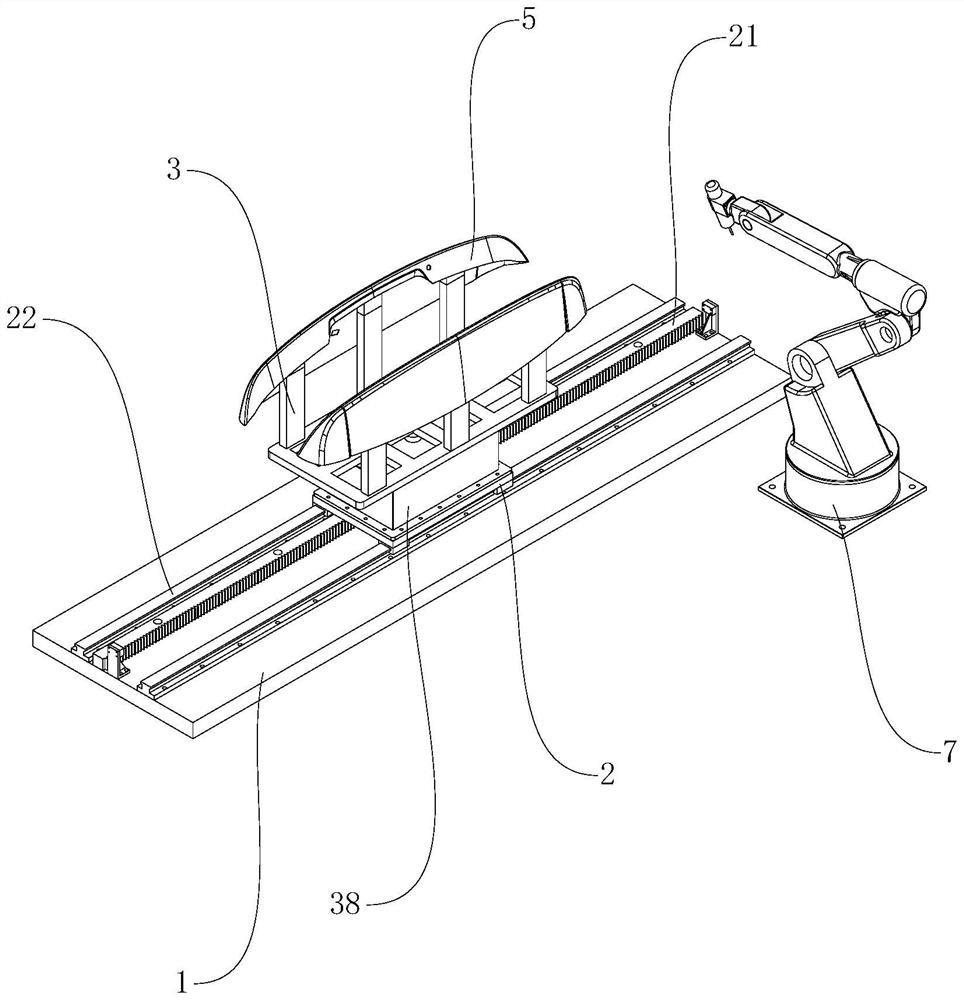

[0046] refer to Figure 1 to Figure 10 A painting device for intelligent manufacturing of new energy automobile parts is shown, including:

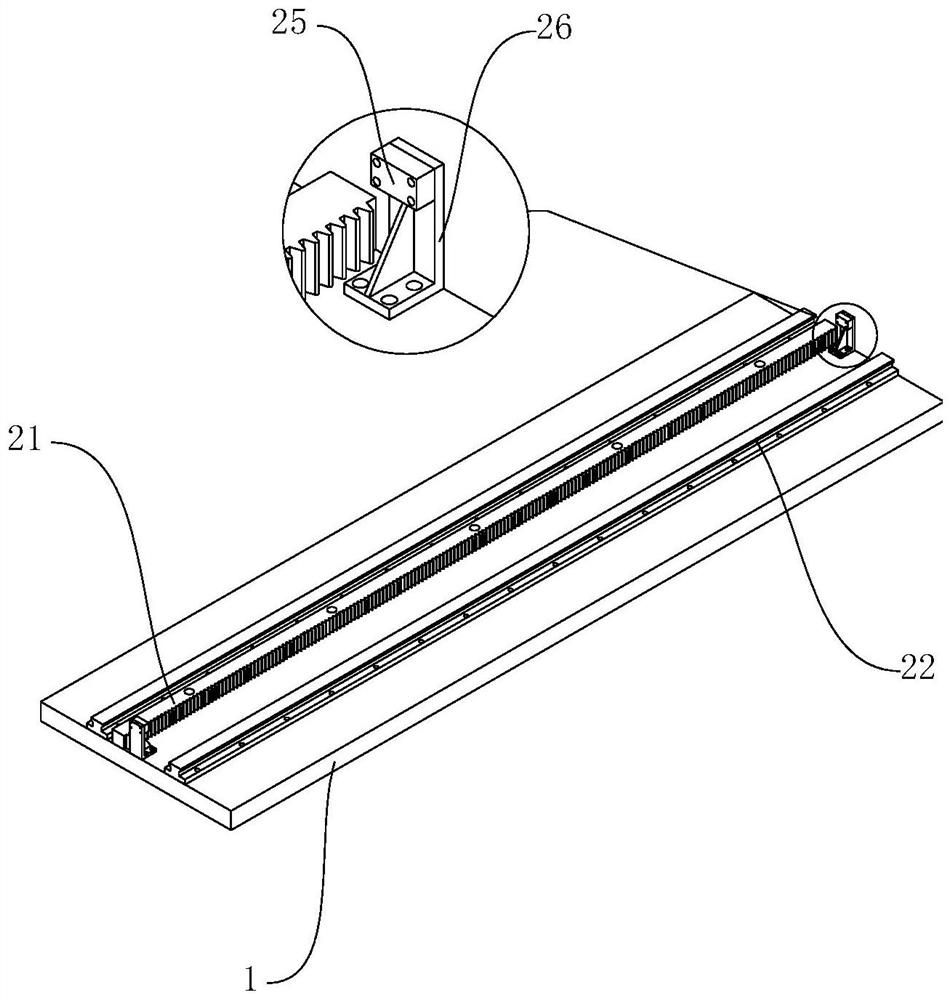

[0047] The strip base 1 is fixedly arranged in a horizontal state;

[0048] The material shifting base 2 is horizontally arranged on the top of the strip base 1 along the length direction of the strip base 1, and the bottom of the shifting base 2 is connected to the strip base 1 through transmission;

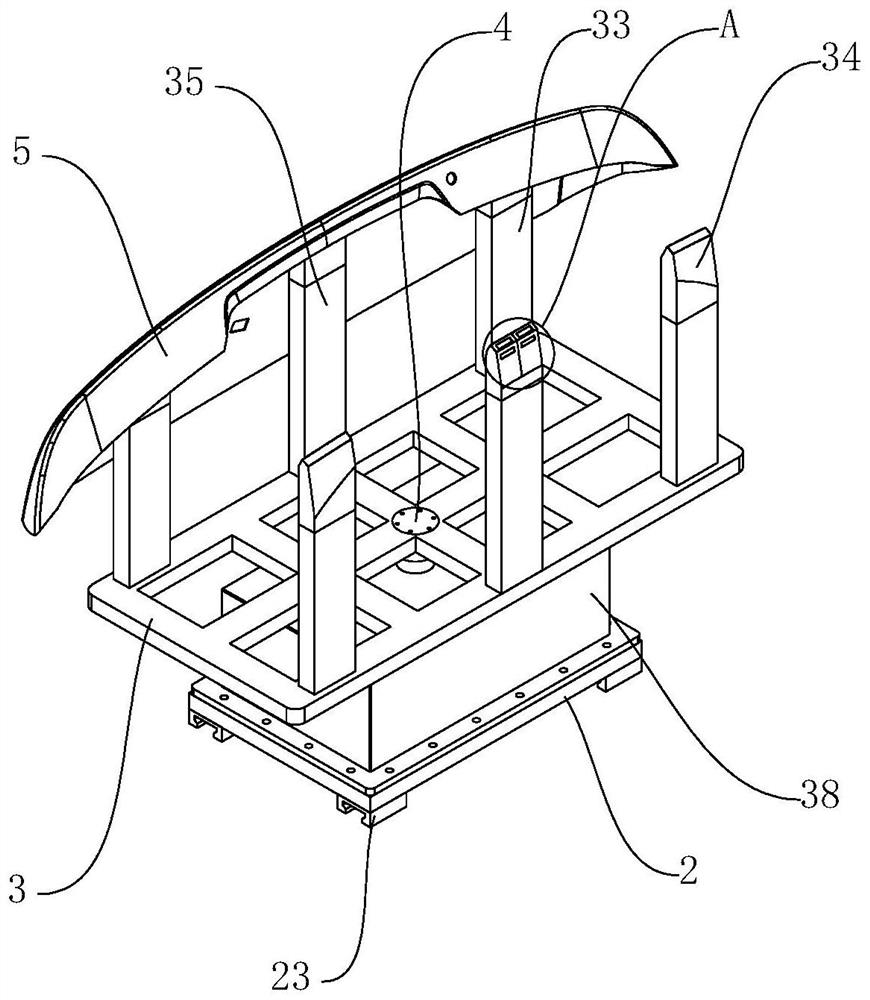

[0049]The fixed platform 3 is arranged directly above the material transfer base 2 through a connecting vertical shaft 4, and the two tail fins 5 to be processed are symmetrically placed on both sides of the top width direction of the fixed platform 3;

[0050] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com