Spraying equipment for LED display screens without board edges

A technology of LED display screen and painting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

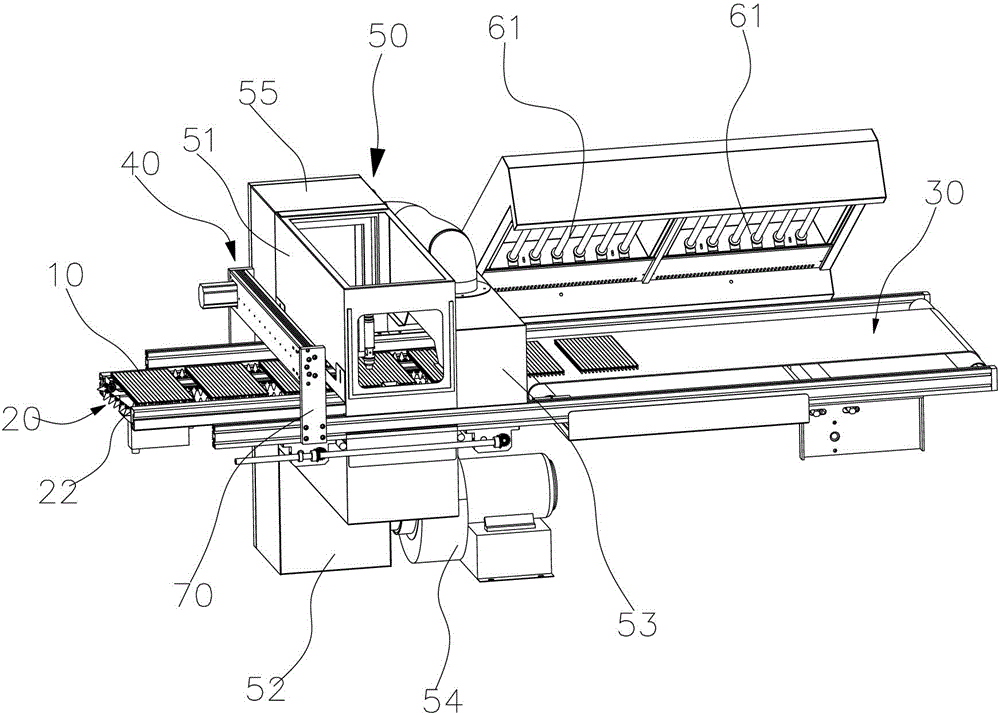

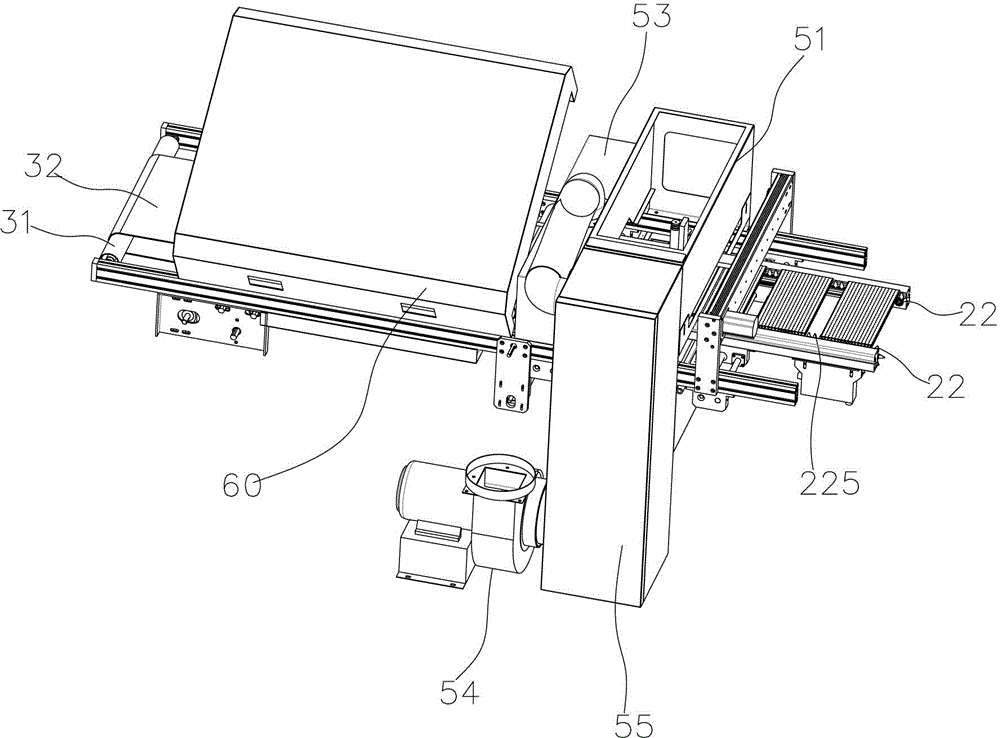

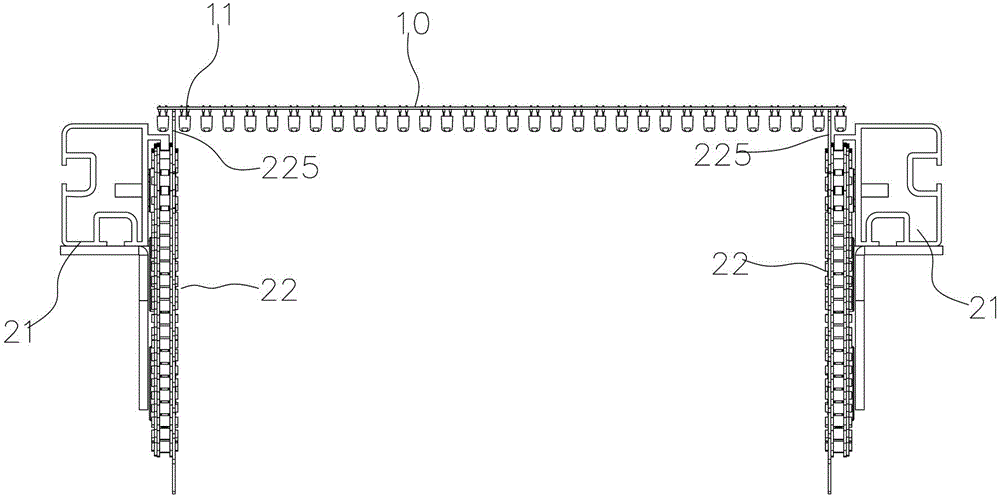

[0030] refer to figure 1 , figure 2 , the edgeless LED display screen painting equipment provided by the present invention is mainly for painting the circuit board 10 of the edgeless LED display screen. A number of neatly arranged LEDs 11 are arranged on the circuit board 10 (hereinafter referred to as the circuit board 10 ) of the edgeless LED display screen. The paint spraying equipment comprises a transmission device 20, a transportation device 30 located in front of the transmission device 20, a spraying device 40 located above the transmission device 20, an exhaust device 50, a drying device 60, and a control system for controlling the coordinated operation of the above devices (Fig. not shown). In this embodiment, the forward direction is the forward direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com