Intelligent door sheet spraying paint spraying production line

A production line and door panel technology, which is applied to the surface coating liquid device, coating, spraying device, etc., can solve the problems that the nozzle cannot reach the lower edge of the peripheral surface, increase the labor intensity of workers, manually turn over the door panel, etc., and achieve lightening Worker labor intensity, compact structure, uniform painting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

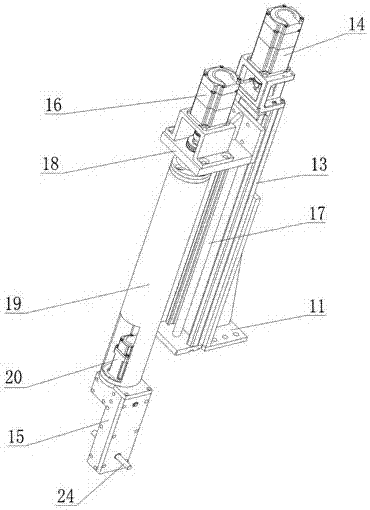

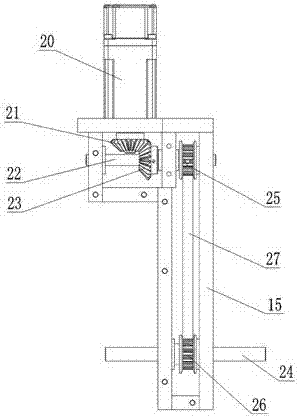

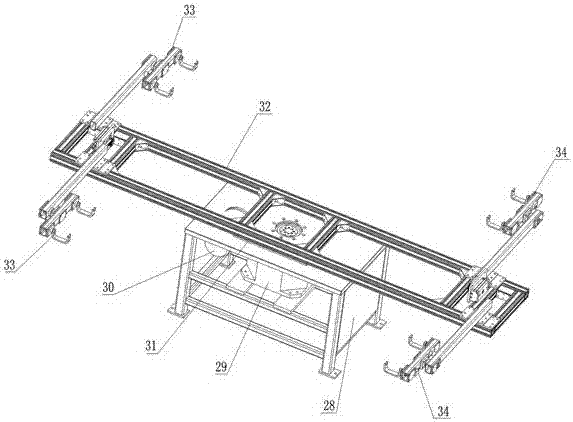

[0030] Such as Figure 1~13 As shown, a painting production line for intelligent spraying door panels, which includes a paint spraying room 101, a rotary table 102, a feeding device 103 and a door panel holding frame 104 arranged in sequence from left to right;

[0031]The spray booth 101 includes a main body 1 of the spray booth. A spray booth is arranged in the main body 1 of the spray booth. The horizontal guide rails 2 are arranged on the front and back sides of the spray booth, and the two horizontal guide rails 2 are equipped with a horizontal slide plate 3 for spraying paint. A rack A4 parallel to the transverse guide rail 2 is provided indoors and on the rear side thereof. A servo motor A5 is fixedly installed on the top of the transverse slide plate 3 on the rear transverse guide rail 2. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com