Pipeline spraying device

A pipe spraying and spray chamber technology, which is applied in the direction of spraying devices, liquid spraying devices, and devices for coating liquid on the surface, etc. It can solve the problems of complex structure of pipeline painting devices, difficulty in spraying paint on pipes, and uneven spraying of paint, etc. problems, to achieve the effect of improving painting efficiency, comprehensive spraying and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

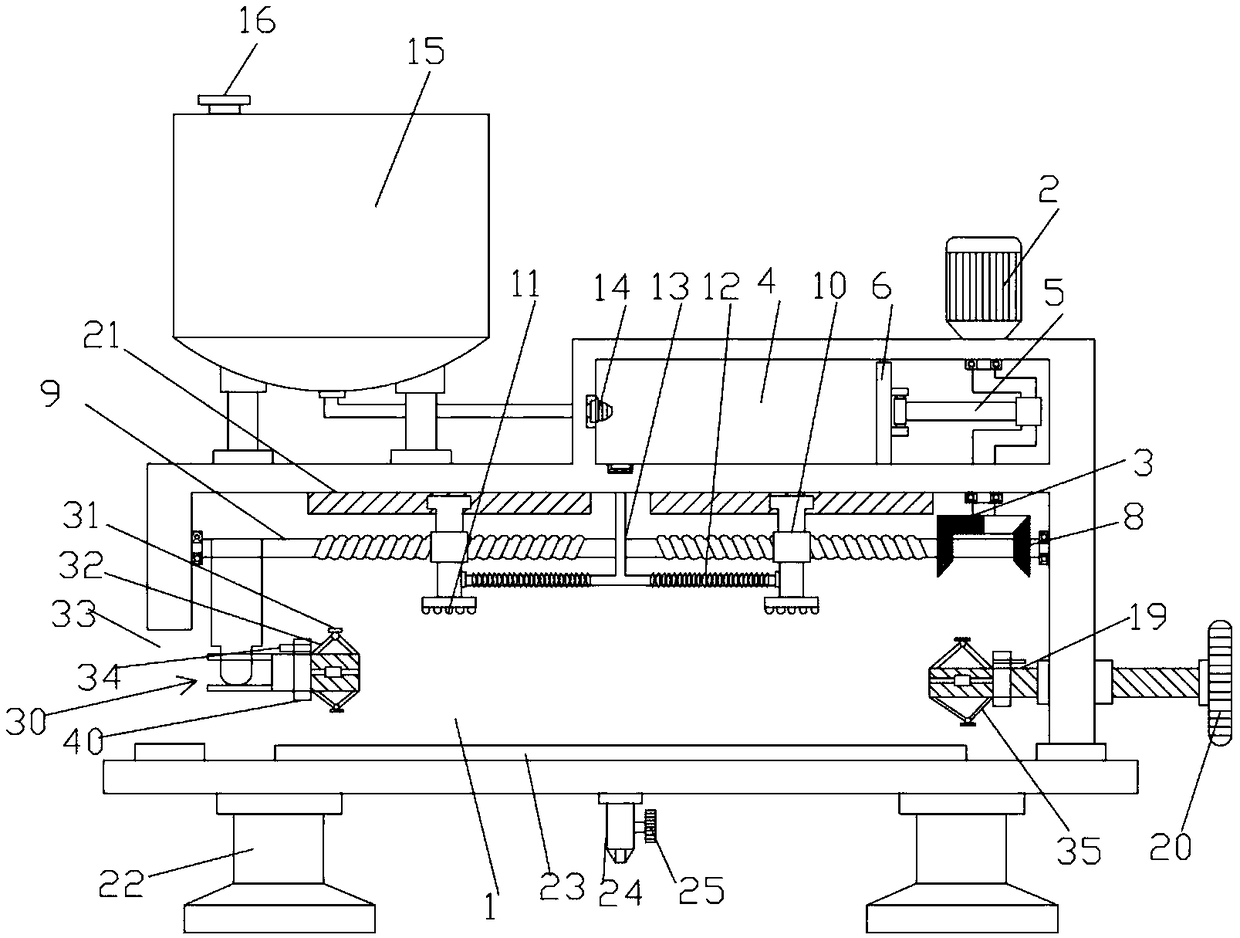

[0047] Such as Figure 1-4 As shown, the pipeline spraying device includes a frame 1, a drive motor 2, a two-way screw mandrel 9, a storage tank 15, an adjustment wheel 20 and a collection tray 23; the upper left side of the frame 1 is fixedly connected to the storage tank 15, The upper end of the material storage tank 15 is provided with a feeding port 16, the upper right side of the frame 1 is provided with a spray chamber 4, and the lower end of the material storage tank 15 is connected to the feeding pipe, and the right end of the feeding pipe is provided with a one-way valve 14, and the one-way valve 14 is connected to the spray chamber 4 The upper part of the spray chamber 4 is fixedly connected to the drive motor 2, the drive motor 2 is electrically connected to the power supply and the switch, the lower end of the drive motor 2 is connected to the upper end of the crankshaft 3 in rotation, the bearing of the crankshaft 3 is connected to the spray chamber 4 in rotation, ...

Embodiment 2

[0051] Such as Figure 5 shown, pipe sprayer, including Rack 1 , a pressurized material storage mechanism located above the frame 1, a feeding mechanism connected to the output end of the storage mechanism, a driving motor 2 located above the feeding mechanism, a transmission mechanism connected to the output end of the driving motor 2, and A paint spraying mechanism connected to the output of the feeding mechanism.

[0052] The above-mentioned feeding mechanism includes a feeding chamber 4 , a feeding piston 6 arranged in the feeding chamber 4 , and an air pressure balance device matched with the feeding piston 6 . A crankshaft 3 is rotatably connected to the downward output end of the above-mentioned drive motor 2, and a connecting rod 5 is rotatably connected between the feed piston 6 and the crankshaft 3. The operation of the drive motor 2 drives the crankshaft 3 to rotate, and the rotation of the crankshaft 3 further drives The connecting rod 5 and the feeding piston 6...

Embodiment 3

[0059] Such as Image 6 with Figure 7 As shown, the pipeline spraying device includes a feeding module, a spraying module and a frame 1 . The upper left side of the above-mentioned frame 1 is fixedly connected to the material storage cylinder 15, the upper end of the material storage cylinder 15 is provided with a feeding port 16 and an air intake hole, the upper right side of the frame 1 is fixedly connected to the air pump 250, and the spray chamber 4 is arranged below the air pump, and the material storage cylinder 15 The lower end communicates with the delivery pipe. The output end of the air pump 250 is connected to the material storage cylinder 15, and the material storage cylinder 15 feeds the spray chamber 4 one-way through the material guide pipe 13 and the one-way valve 14 in sequence. The upper part of the spray chamber 4 is fixedly connected to the driving motor 2, the lower end of the driving motor 2 is connected to the upper end of the bearing 3, and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com