Wooden door processing device with rotational double-side paint spraying function

A processing device and function technology, which is applied in the spraying device, spraying room and other directions, can solve the problems of low efficiency of wooden door spraying, affecting the work efficiency of staff, trouble in fixing and turning the wooden door, etc., to achieve guaranteed effect, high practicability, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

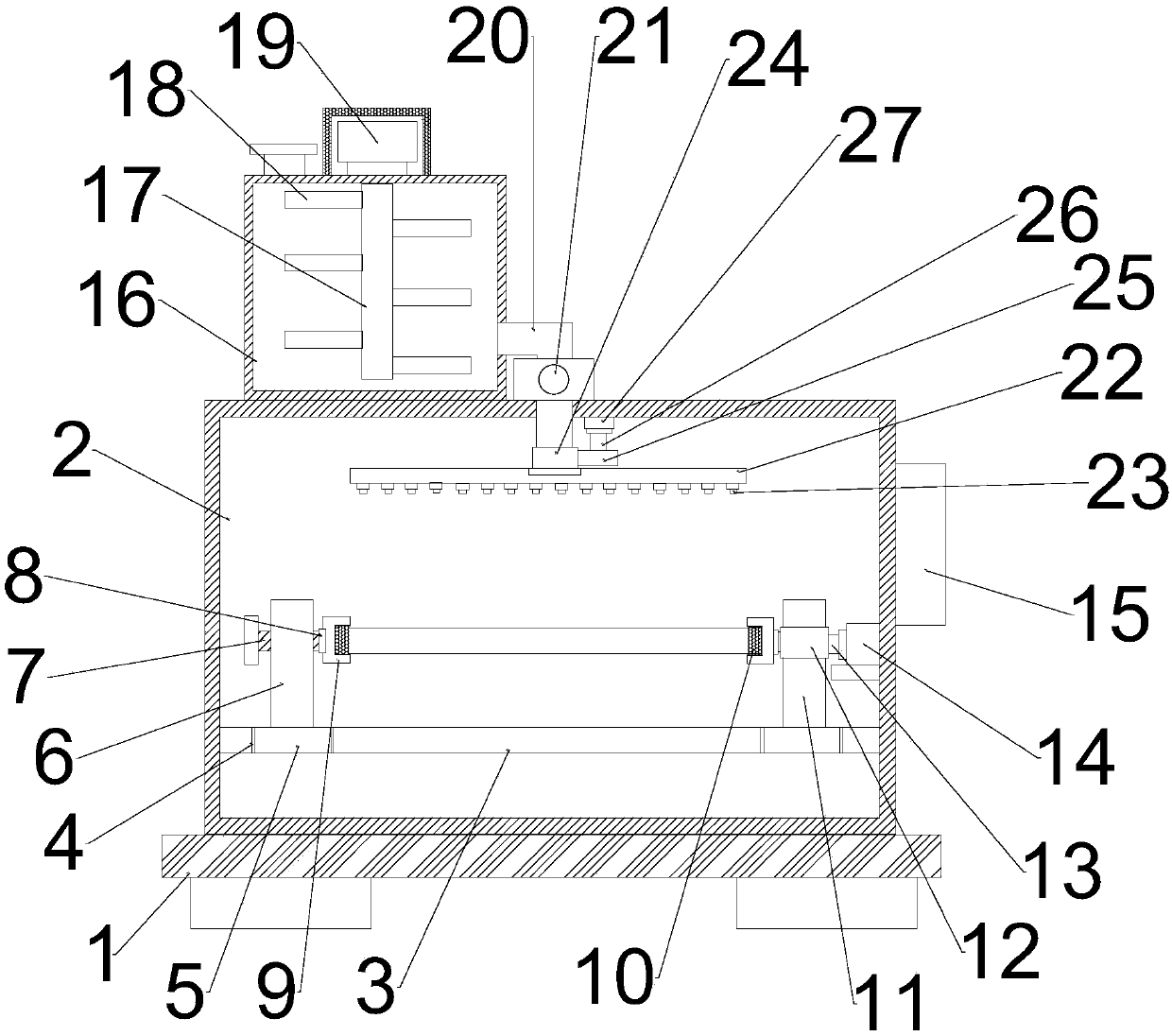

[0011] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a wooden door processing device with the function of rotating double-sided painting proposed by the present invention.

[0012] refer to figure 1 , a wooden door processing device with the function of rotating double-sided painting proposed by the present invention, comprising a fixed base 1, a painting room 2 and a working support plate 3, wherein:

[0013] The fixed base 1 is arranged at the lower end of the spray booth 2, the working support plate 3 is arranged inside the spray booth 2, and the working support plate 3 is provided with two chutes 4, and a slide block 5 is arranged in the chute 4, and the slide on the left side The block 5 is provided with a left fixed plate 6, the slide block 5 on the right side is provided with a right fixed plate 11, the left fixed plate 6 is provided with a limit threaded column 7, and the limit threaded column 7 is provided with a rotary fixture 8, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com