Method for preparing beta titanium alloy strip coil

A beta titanium alloy, coil technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of surface cracks, material plasticity deterioration, etc., achieve effective control of the structure and inhibit the precipitation of harmful phases. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

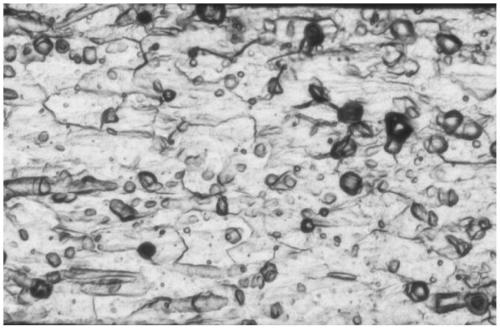

Image

Examples

Embodiment 1

[0029] This example provides a kind of preparation method of β titanium alloy coil, comprises the following steps:

[0030] S1: attaching the pure titanium sheet to the upper and lower surfaces of the β-titanium alloy slab to obtain a β-titanium alloy prefabricated slab;

[0031] S2: performing heating and heat preservation treatment on the β titanium alloy prefabricated slab obtained in step S1;

[0032] S3: rolling the β-titanium alloy prefabricated slab processed in step S2 to the target thickness, opening the laminar flow cooling device at the outlet of the hot rolling end stand, and forcing the finished coil to cool after the strip head bites in, Coiling starts at the coiling temperature until the whole roll is rolled off the line, and the continuous hot rolling includes rough rolling and finish rolling.

[0033] Before step S1, the surface of the β titanium alloy slab is cleaned and polished.

[0034] The pure titanium sheet in step S1 includes TA1 pure titanium sheet ...

Embodiment 2

[0040] In this example, the β-titanium alloy coil A was prepared by the preparation method of Example 1. Concrete steps and process parameters are as follows:

[0041] This example provides a kind of preparation method of β titanium alloy coil, comprises the following steps:

[0042] S1: attaching the pure titanium sheet to the upper and lower surfaces of the β-titanium alloy slab to obtain a β-titanium alloy prefabricated slab;

[0043] S2: performing heating and heat preservation treatment on the β titanium alloy prefabricated slab obtained in step S1;

[0044] S3: rolling the β-titanium alloy prefabricated slab processed in step S2 to the target thickness, opening the laminar flow cooling device at the outlet of the hot rolling end stand, and forcing the finished coil to cool after the strip head bites in, Coiling starts at the coiling temperature until the whole roll is rolled off the line, and the continuous hot rolling includes rough rolling and finish rolling.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com