Boiler waste heat recovery system

A recovery system, boiler waste heat technology, applied in steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problem of high boiler flue gas outlet temperature, achieve high waste heat recovery rate, avoid blockage, and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

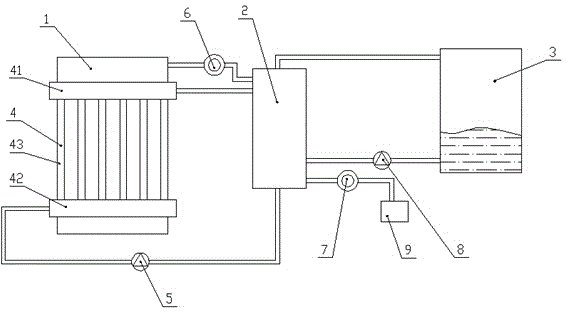

[0024] This embodiment provides a boiler waste heat recovery system, such as figure 1 As shown, the boiler waste heat recovery system includes a boiler 1 , waste heat recovery equipment, a heat exchanger 2 and a steam tank 3 . The waste heat recovery equipment transfers the waste heat of the boiler to the steam tank 3 through the heat exchanger 2, heats the cold water in the steam tank 3 and converts it into steam and stores it in the steam tank 3.

[0025] The waste heat recovery equipment includes a heat exchange tube assembly 4 arranged on the outer periphery of the boiler 1 , and the heat exchange tube assembly 4 , the first circulating pump 5 and the heat exchanger 2 form a refrigerant circulation loop. The heat exchange tube assembly 4 includes a first annular pipe 41 surrounding the upper part of the boiler 1, a second annular pipe 42 surrounding the lower part of the boiler 1, and a plurality of straight pipes 43 connecting the first annular pipe 41 and the second annu...

Embodiment 2

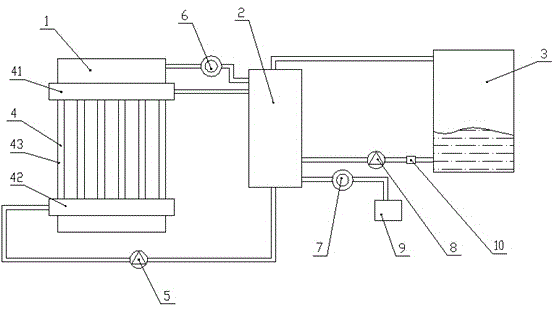

[0035] This embodiment provides a boiler waste heat recovery system, such as figure 2 As shown, the boiler waste heat recovery system includes a boiler 1 , waste heat recovery equipment, a heat exchanger 2 and a steam tank 3 . The waste heat recovery equipment transfers the waste heat of the boiler to the steam tank 3 through the heat exchanger 2, heats the cold water in the steam tank 3 and converts it into steam and stores it in the steam tank 3.

[0036] The difference is that, in this embodiment, a filter device 10 is provided on the outlet pipeline of the cold water outlet of the steam tank 3 . By setting the filter device 10, the water in the pipeline can be filtered to further avoid the blockage of the pipeline and ensure the reliability of use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com