Self-adhering polymer modification bitumen composite anti-root water-proof coiled material and preparing method thereof

A technology for modifying asphalt and waterproofing membranes, which is applied to asphalt layered products, chemical instruments and methods, and roofs using flexible materials, etc. Excellent performance, excellent waterproof, good waterproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

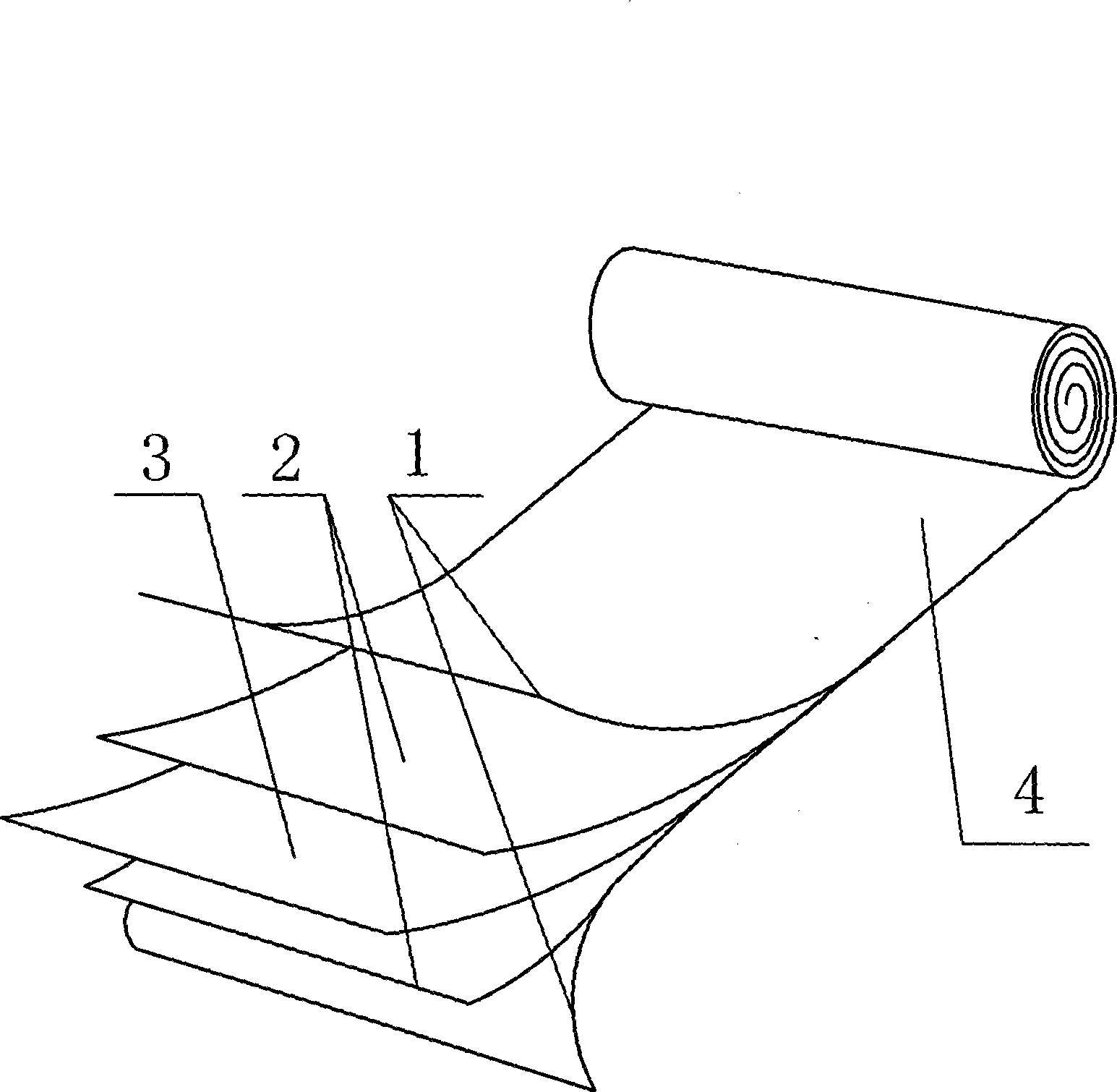

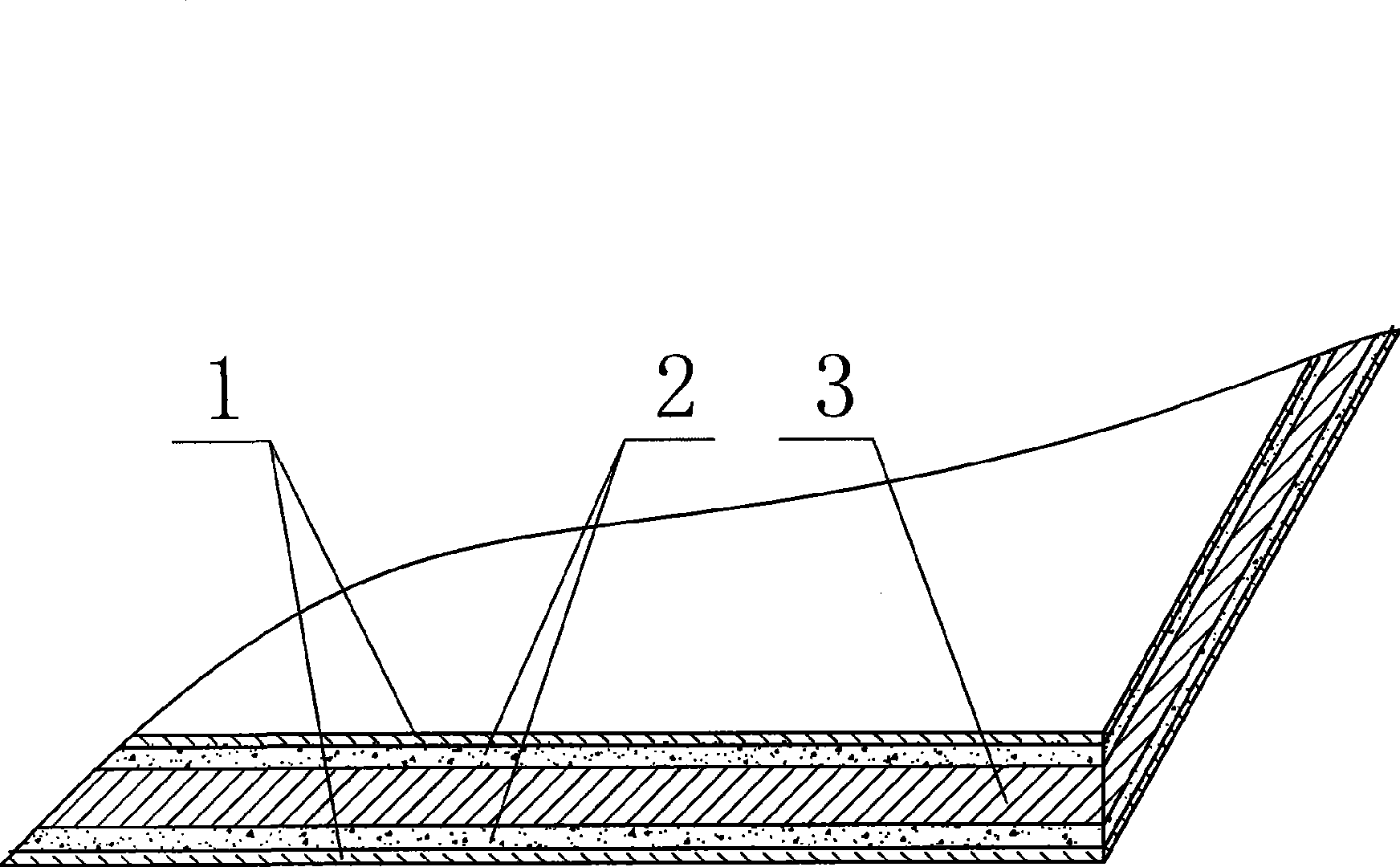

[0015] Preparation process of the present invention

[0016] 1. Preparation of self-adhesive chemical anti-root waterproof layer

[0017] The self-adhesive chemical anti-root waterproof layer is composed of self-adhesive polymer modified asphalt anti-root mixture made of the following raw materials by weight, asphalt 45-55, recycled styrene-butadiene rubber powder 20-30, base oil 5-15, Heavy calcium powder 15-20, chemical root inhibitor 0.8-1.2.

[0018] The asphalt in the self-adhesive polymer modified asphalt anti-root mixture of the present invention is road petroleum asphalt, the chemical anti-root agent adopts phenoxy fatty acid lipid chemical anti-root agent, and the physical anti-root waterproof layer is polyethylene, polyvinyl chloride, A kind of root puncture-resistant waterproof material such as high-density polyethylene geomembrane and polyethylene polypropylene fiber.

[0019] The polymer in the self-adhesive polymer modified asphalt root-resistant mixture of the...

Embodiment 1

[0021] Embodiment 1 (every part by weight is 100 kilograms)

[0022] Add 4,600 kg of No. 90 asphalt into the mixing tank, raise the temperature to 215°C under stirring, add 2,900 kg of regenerated styrene-butadiene rubber powder, and stir for 90 minutes at 215°C. At this time, add 900 kg of base oil, and then add heavy calcium Powder 1600 kg, lower the temperature to 130°C-150°C, finally add 100 kg of chemical root inhibitor, and stir for 30 minutes to obtain the finished self-adhesive polymer modified asphalt root-resistant waterproof mixture for later use.

Embodiment 2

[0024] Add 4,800 kg of No. 100 asphalt into the mixing tank, raise the temperature to 210°C under stirring, add 3,000 kg of recycled SBR powder, stir at 205°C for 90 minutes, add 700 kg of base oil, and add heavy calcium at this time Powder 1700 kg, lower the temperature to 130°C-150°C, finally add 80 kg of chemical anti-root agent, and stir for 30 minutes to obtain the finished self-adhesive polymer modified asphalt anti-root waterproof mixture for future use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com