Organic electroluminescence device and fabricating method thereof

a technology of organic electroluminescence and fabrication method, which is applied in the direction of discharge tube luminescnet screen, sustainable manufacturing/processing, discharge tube manufacturing, etc., can solve the problems of not being good for mass production of oel device, and not good for reducing production cost either, so as to improve light emission effect and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

The First Embodiment

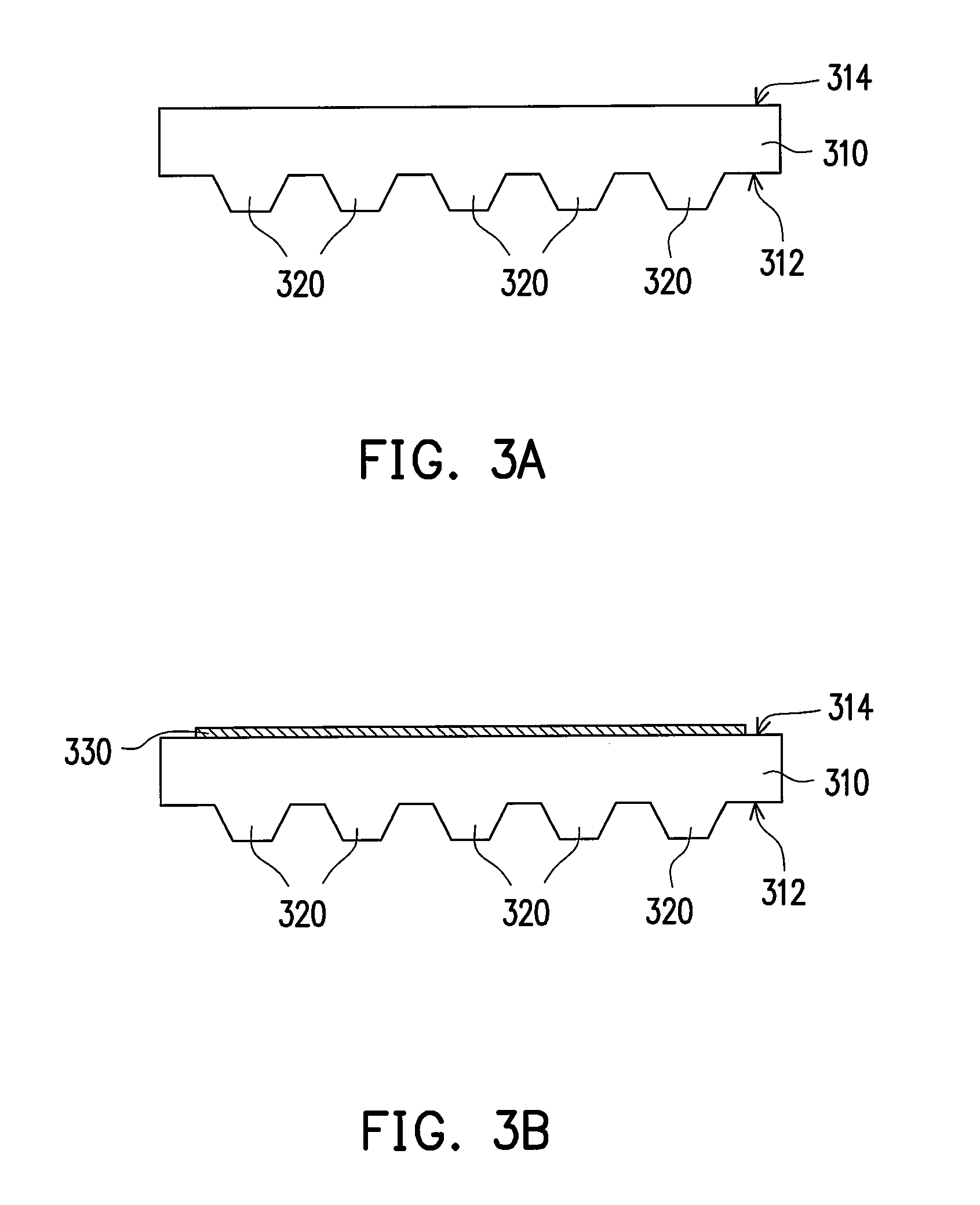

[0053]FIGS. 3A˜3F are schematic sectional views of a flow of fabricating the OEL device of the first embodiment of the present invention. The embodiment is about the fabricating of a bottom emission OEL device.

[0054]Referring to FIG. 3A, firstly a polymeric substrate 310 having a first surface 312 and a second surface 314 is provided, wherein a plurality of light enhanced structures 320 is formed on the first surface 312. In the present embodiment, the method of forming the light enhanced structures 320 on the first surface 312 may be molding method or injection molding method. Particularly, the light enhanced structures 320 and the polymeric substrate 310 may be the construction that is integrated as one piece. As compared with the method of fabricating the microlens array 212 by RIE as shown in FIG. 2 in the conventional art, it is easier to fabricate the polymeric substrate 310 with the light enhances structures 320, so it can be in mass production so as to lo...

second embodiment

The Second Embodiment

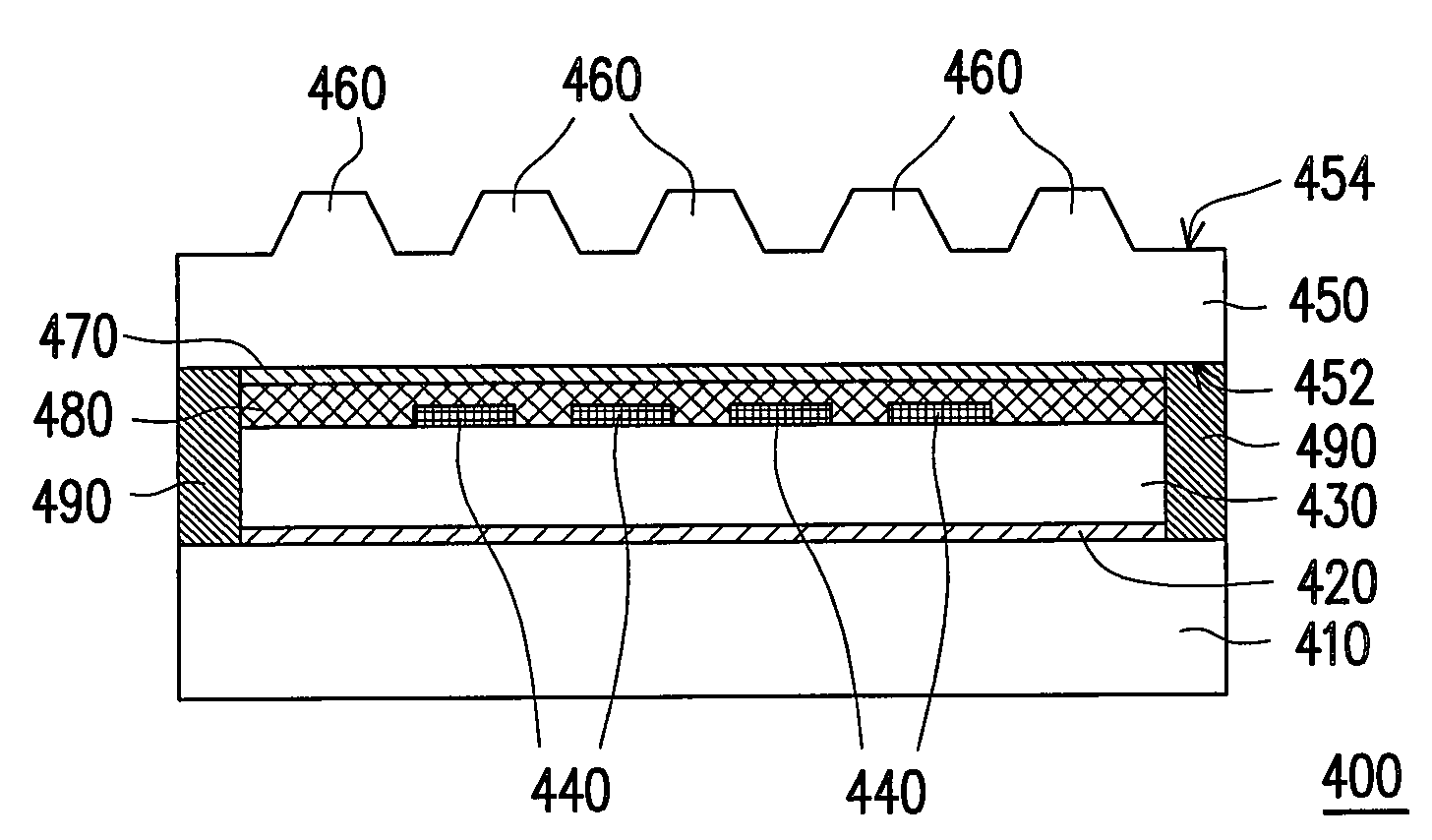

[0066]FIGS. 4A˜4F are schematic sectional views of a flow of fabricating the OEL device of the second embodiment of the present invention. The embodiment is about the fabricating of a top emission OEL device.

[0067]Referring to FIG. 4A, firstly a substrate 410 is provided. The substrate 410 may be a glass substrate, a plastic substrate or another kind of substrate.

[0068]Next, referring to FIG. 4B, a first electrode 420 is formed on the substrate 410. In an embodiment, the method of forming the first electrode 420 may be sputtering, evaporation method or another suitable method. The material of the first electrode 420 is, for example, metal, and the type of the metal is not limited in the present invention.

[0069]Then, referring to FIG. 4C, an organic light emitting layer 430 is formed on the first electrode 420. In an embodiment, the method of forming the organic light emitting layer 430 is, for example, coating method, evaporation method or another suitable metho...

third embodiment

The Third Embodiment

[0077]The third embodiment is similar to the second embodiment. It is also about the fabricating method and the structure of a top mission OEL device. FIG. 5 is a schematic view of the OEL device of the third embodiment of the present invention.

[0078]Referring to FIGS. 4A˜4E and FIG. 5, firstly, in the third embodiment, the steps as shown in FIGS. 4A˜4D are used to fabricate an OEL device having the substrate 410, the first electrode 420, the organic light emitting layer 430 and the second electrode 440. Then, as shown in FIG. 4E, a polymeric substrate 450 is provided.

[0079]It should be noted that the difference between the present embodiment and the second embodiment is that in the third embodiment, the anti-oxidation layer 470 is not formed between the second electrode 440 and the polymeric substrate 450. As shown in FIG. 5, when the anti-oxidation layer 470 is formed on the second surface 454, the polymeric substrate 450 is directly disposed on the second elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com