Anti-knock power battery apparatus

A technology for power battery packs and battery packs, applied in battery pack components, secondary battery manufacturing, circuits, etc., can solve the problems of poor battery pack working stability, unfavorable cell heat dissipation, unreliable battery electrical contact, etc. Anti-vibration performance, extended operating life, the effect of maintaining reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with the best embodiment shown in the accompanying drawings, it will be further described in detail.

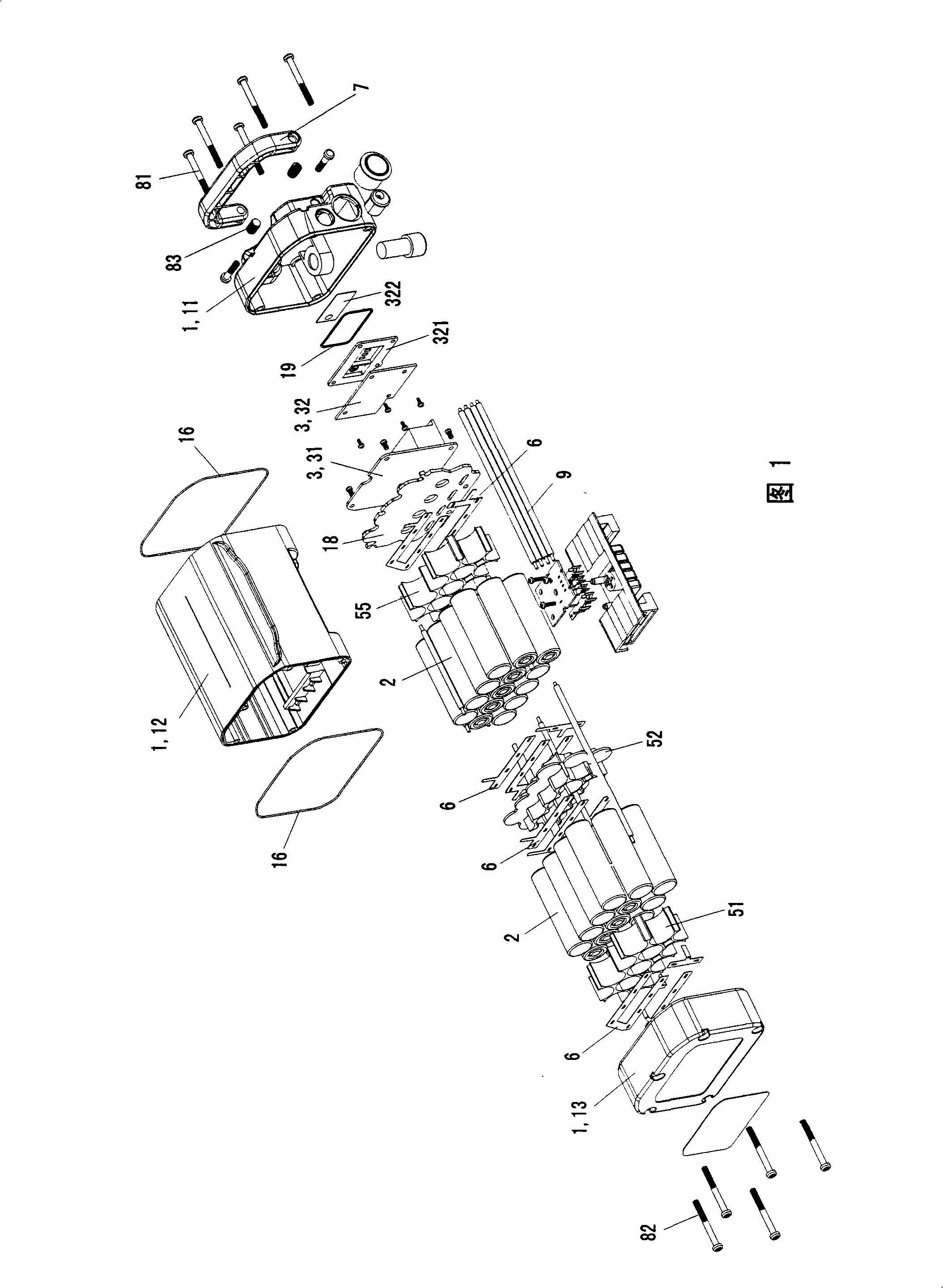

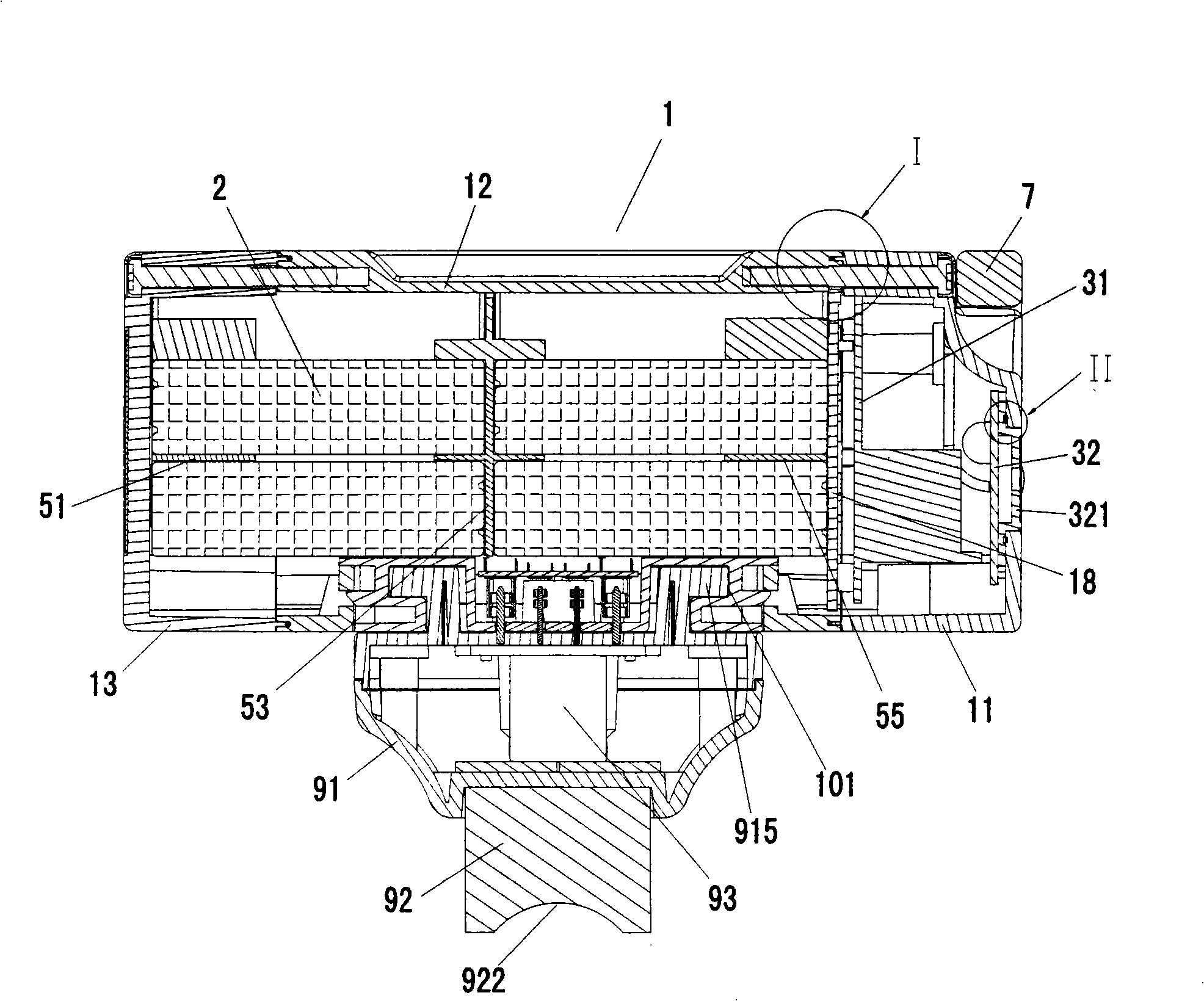

[0024] Figure 1 and image 3 As shown, the anti-vibration battery pack device of the present invention includes a housing 1, a plurality of battery units 2 placed in the housing 1, a charge-discharge and charge-discharge protection circuit board 3 electrically connected to the plurality of battery units 2, As well as a support structure defining the positions of the plurality of battery pack units 2 , the support structure further includes: a lower support 51 , an upper support 55 and at least one middle support 52 between the lower support 51 and the upper support 55 .

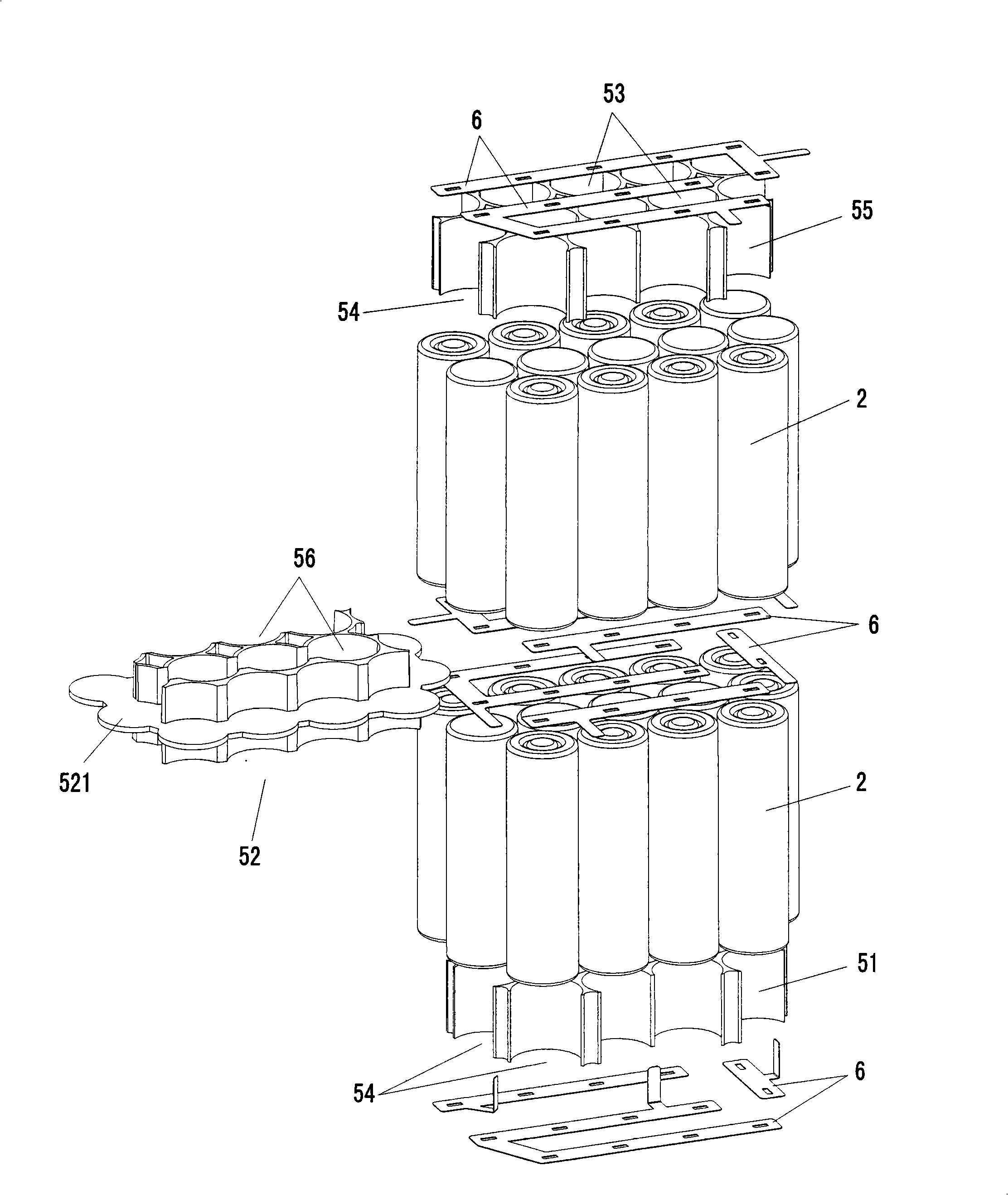

[0025] Such as figure 2 As shown, in this embodiment there are two battery pack units 2 up and down and a middle bracket 52 connecting the two battery pack units 2 . The lower support 51 and the upper support 55 are uniformly arranged with positioning holes 53 having the same nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com