Thermal shock joint experiment device for nanometer thermal insulation material in extreme high-temperature environment

A technology of nano-heat insulation materials and high-temperature environment, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., which can solve the problems of thermal shock joint test of anti-vibration performance of nano-heat-proof materials, and achieve reliability, The effect of ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

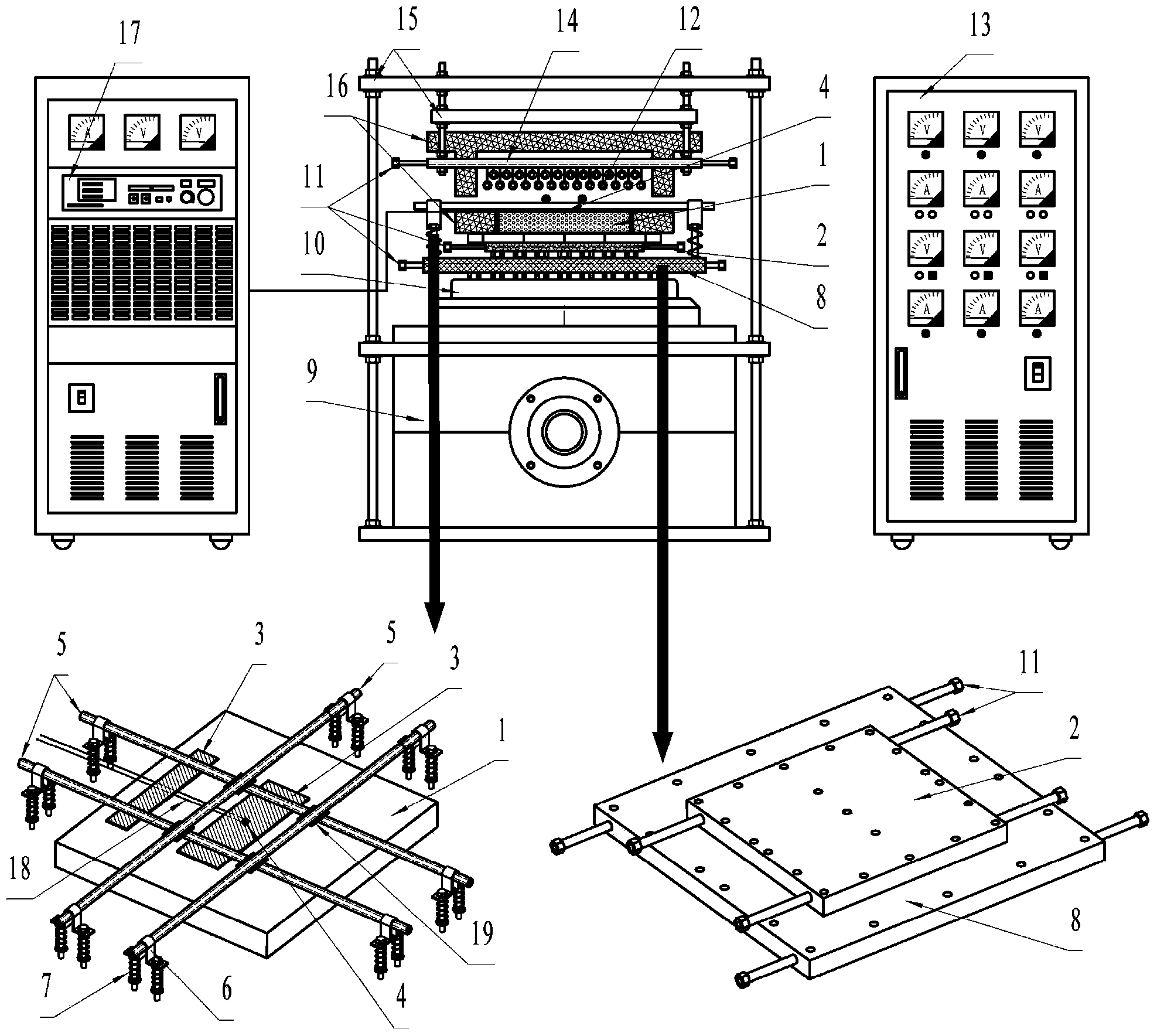

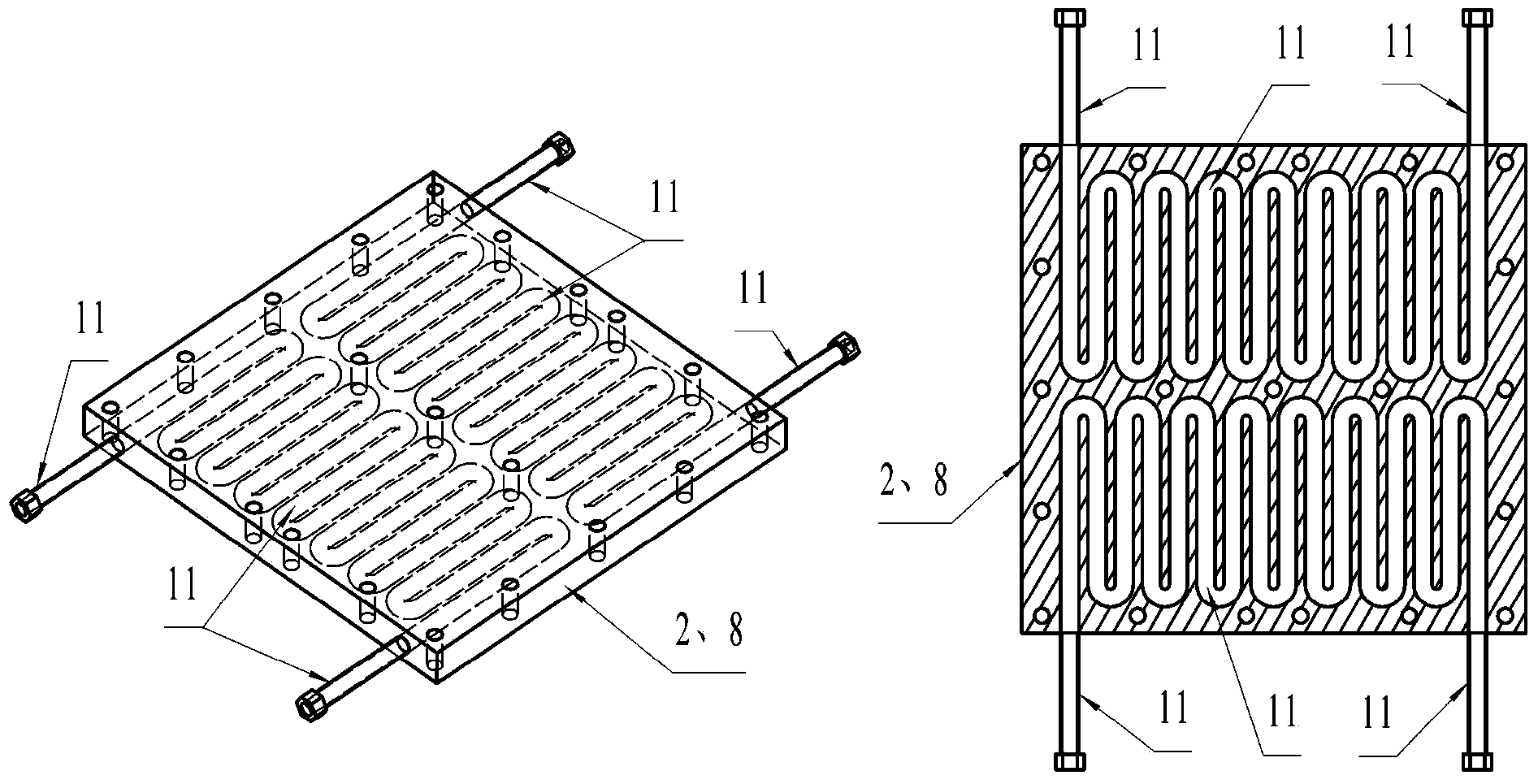

[0034] like figure 2 and image 3 As shown, the present invention consists of a nano-insulation material test piece 1 for a hypersonic aircraft, a first-level thermal insulation platform 2, a precious metal platinum-rhodium tablet 3, a double platinum-rhodium temperature sensor 4, a hollow ceramic rod 5, a semicircular clamp 6, Tension spring 7, secondary heat insulation platform 8, vibration table body 9, excitation platform 10, water cooling channel 11, infrared radiation heat source array 12, high-power regulator 13, fixed electrode 14, coupling bracket 15, lightweight heat insulation The material 16 , the vibration table drive controller 17 , the ceramic tube 18 and the high temperature resistant flexible thin felt 19 are composed. The nano-insulation material test piece 1 of the hypersonic aircraft is fixed on the first-level heat insulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com