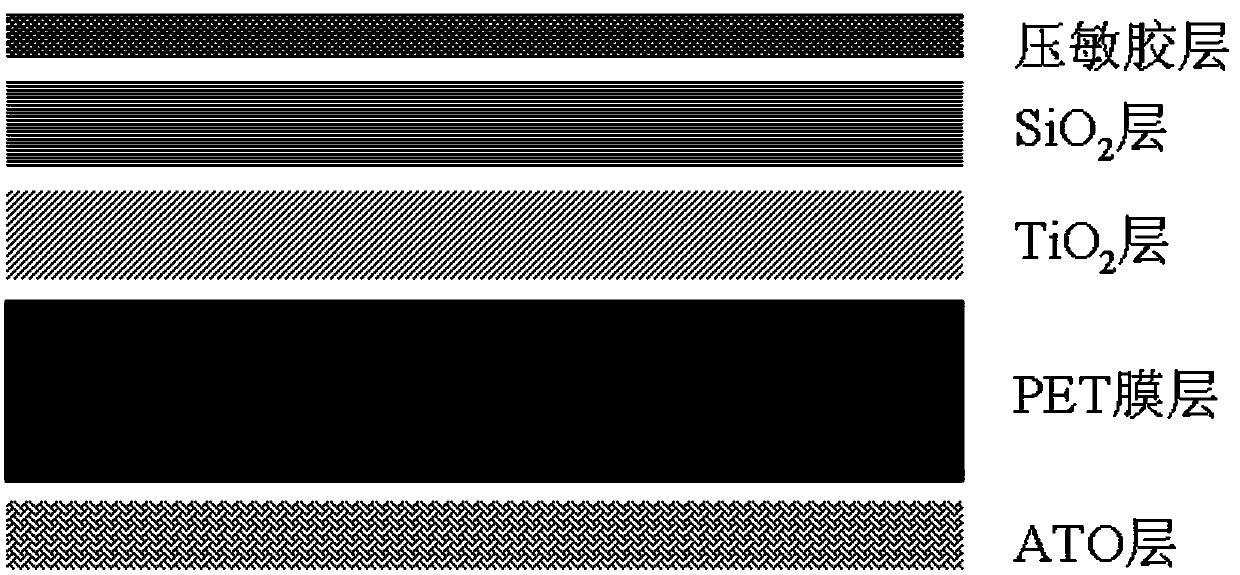

Flexible transparent nano heat-insulation film and preparation method thereof

A nano-insulated and transparent technology, applied in film/flake adhesives, coatings, reflective/signal coatings, etc., can solve the problems of difficult peeling, reduced film insulation performance, easy to absorb dust, etc. Antistatic properties, improve thermal insulation efficiency, and the effect of not easily adsorbing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: A kind of preparation method of flexible transparent nano heat insulation film

[0048] 1) TiO 2 Preparation of coating slurry

[0049] Take 100mL of TiCl with a concentration of 0.2mol / L 4 Aqueous solution, adjust TiCl with a mass concentration of 5% ammonia water 4 The pH of the aqueous solution is 9, and white ortho-titanic acid precipitates are obtained; wash with deionized water until there is no chloride ion in the system; disperse the ortho-titanic acid precipitates in 100 mL of hydrogen peroxide solution with a mass concentration of 30%, and wait until the precipitation is complete After dissolving, heat and reflux for 6 hours to obtain anatase TiO with a particle size of 20-40nm 2 Sol, add film-forming agent fluorocarbon resin to the sol, and evenly disperse to obtain TiO 2 Coating slurry, the mass fraction of fluorocarbon resin in the sol is 0.5%;

[0050] 2)SiO2 2 Preparation of coating slurry

[0051] SiO with a particle size of 40-80nm ...

Embodiment 2

[0061] Repeat Example 1, the difference is only in step 3) in the preparation of ATO slurry, the solid content of ATO nanoparticles is 2.50%, and the solid content of polyurethane film former is 0.50%.

Embodiment 3

[0063] Repeat Example 1, the difference is only in step 3) in the preparation of ATO slurry, the solid content of ATO nanoparticles is 2.73%, and the solid content of polyurethane film former is 0.27%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com