Yarn heater

A heating device and yarn technology, applied in the field of yarn heating devices, can solve the problems of increased power consumption of the heater and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

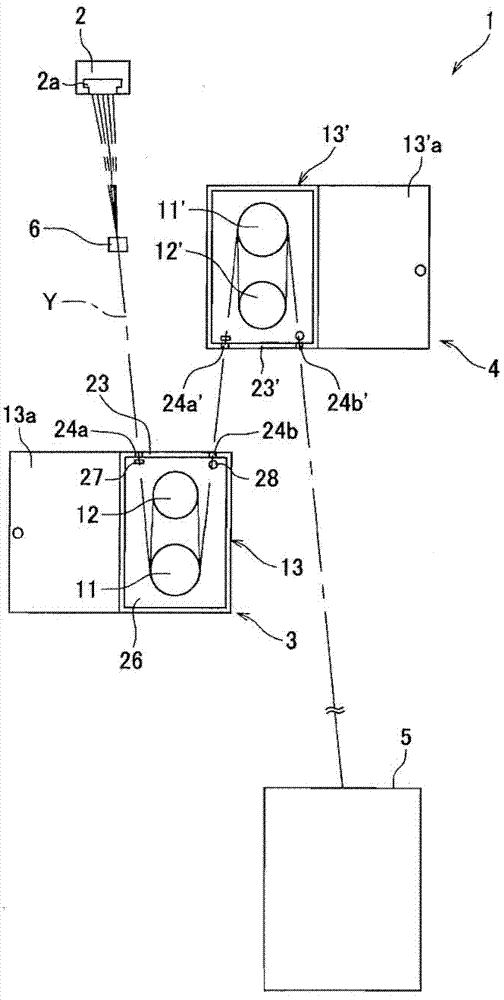

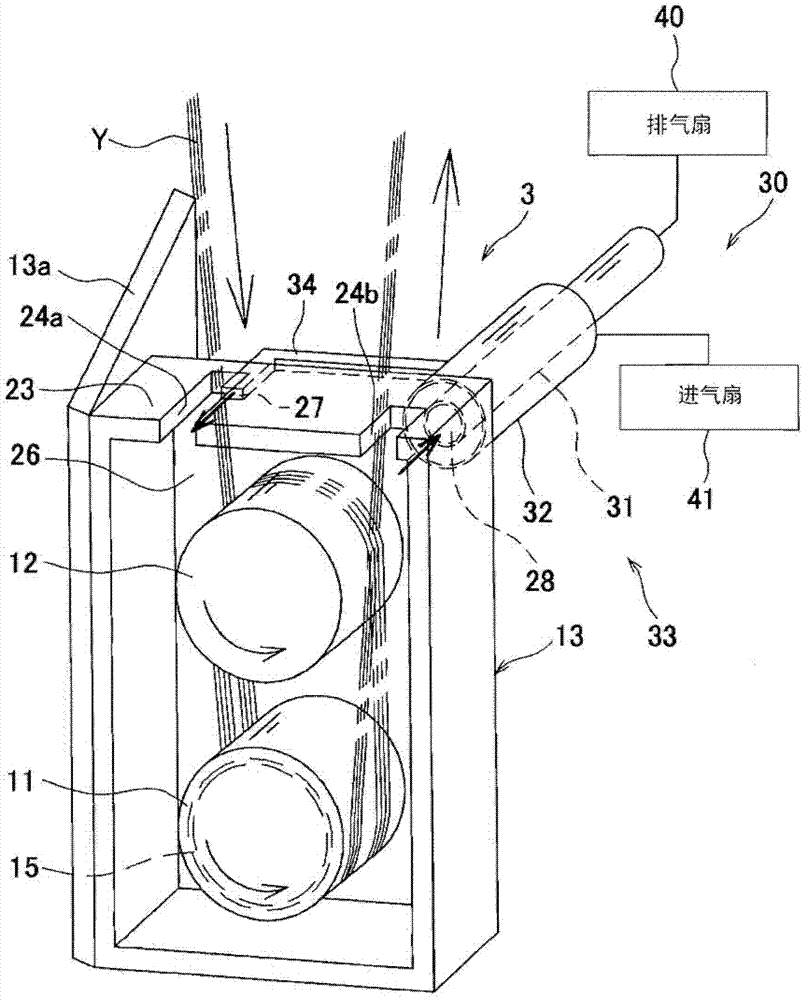

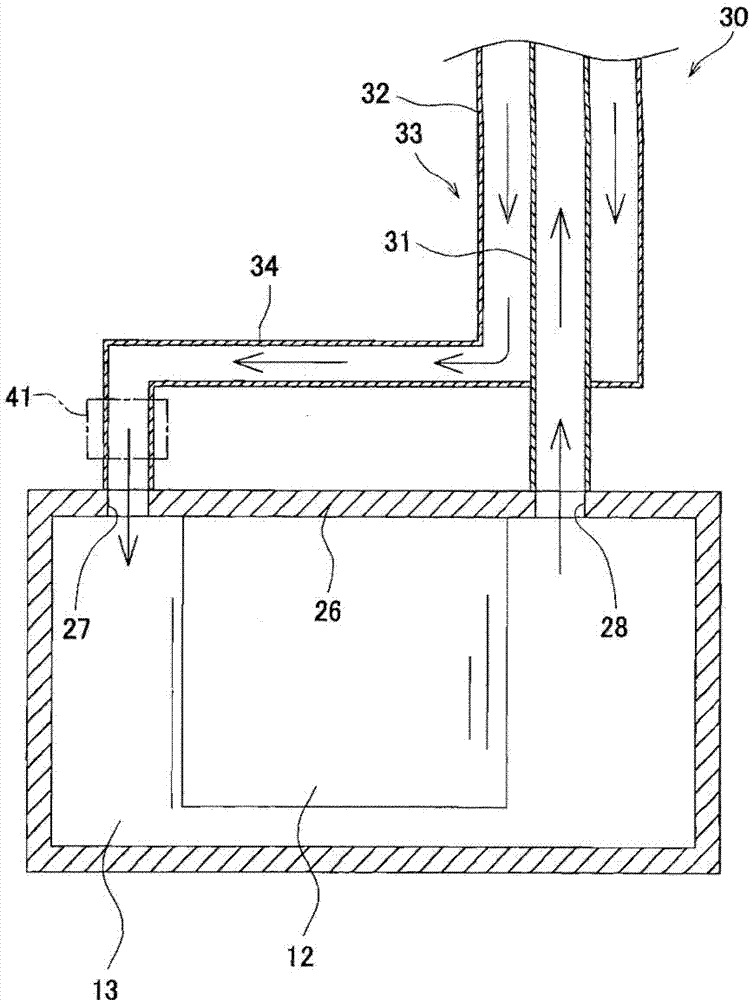

[0032] Preferred embodiments of the present invention will be described below. figure 1 It is a schematic structural diagram of the yarn manufacturing apparatus of this embodiment. Such as figure 1 As shown, the yarn manufacturing device 1 includes a spinning machine 2, an oil supply unit 6, two roller units 3 and 4 (yarn heating device), a winding machine 5, and the like.

[0033] The spinning machine 2 spins the yarn Y (so-called multifilament) composed of a plurality of single fibers discharged from the spinning spinneret 2a downward. The oil supply unit 6 attaches oil to the plurality of yarns Y spun from the spinning machine 2 and run. The roller units 3 and 4 stretch and feed the plurality of yarns Y spun from the spinning machine 2 and to which the oil agent is adhered while being heated. The winder 5 winds the plurality of yarns Y stretched and sent by the roller units 3 and 4 onto a bobbin (not shown).

[0034] In addition, among the configurations of the respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com