Multi-wall interlayer hollow plastic heat preserving and cold insulating pipeline

A hollow tube and plastic technology, which is applied in the direction of thermal insulation protection of pipelines, thermal insulation, pipeline protection, etc., can solve problems such as poor thermal insulation performance, and achieve the effects of short production cycle, simple processing technology and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

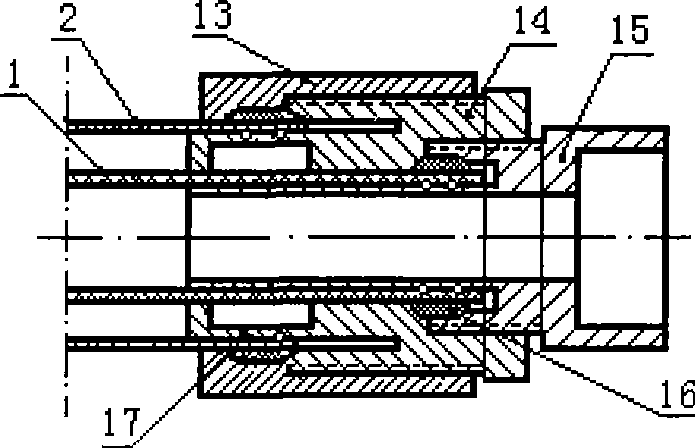

[0042] Embodiment 1: a kind of multi-wall interlayer hollow plastic insulation, cold insulation pipeline, such as Figure 13 , Figure 14 As shown, the pipe has six walls and five hollows, and five layers of reinforcement inside the wall. The raw materials used are two kinds, plastic and compound. Extrusion processing is divided into two schemes, scheme 1, plastic pipe walls (1), (2), (6) planting ribs (4) extruder, functional layer (5) extruder, composite with six walls and five layers of ribs Pipe die extrusion processing. The functional layer extruder extrudes the mixed flow material (45) through the secondary flow divider (55), the plastic pipe wall extruder flow with the compound pipe head, the main flow divider cone (49), and the primary flow divider (53). Material (46) (50) confluence, makes six wall five hollow pipes. Scheme two uses three groups of double-walled single- and double-bar composite pipe heads and six extruders, pipe wall (1) (6) planting bars (4) extru...

Embodiment 2

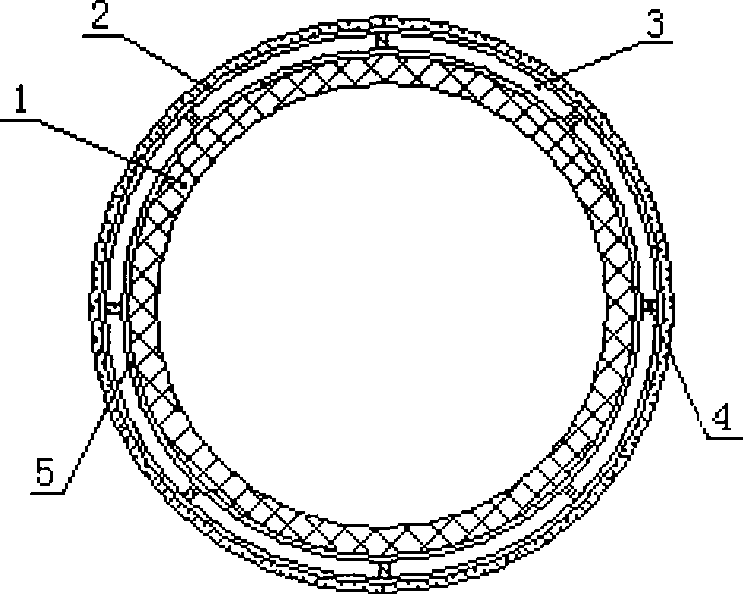

[0044] Embodiment 2: a kind of multi-wall interlayer hollow plastic insulation, cold insulation pipeline, such as image 3 , Figure 4 , as shown in Figure 9, the pipe wall is formed by co-extrusion process of two kinds of plastics. It is made of steel, copper and plastic composite pipe head extruding double-walled hollow plastic embedded metal pipe with high temperature-resistant plastic material, and then embedded in another head and welded with the extruded pipe wall to form it. Multi-wall interlayer hollow plastic-embedded metal insulation pipes with resistance to 360°C of different materials. If the melting temperature of the two plastics differs little, multi-wall steel, copper, and plastic composite pipe heads ( Figure 16 ) Extruded at one time. Plastic embedded metal pipes use seamless pipes, and pipes with large diameters also use straight seam welded pipes to eliminate the expansion and wrapping marks of plastic and metal wires and ensure the covering effect of p...

Embodiment 3

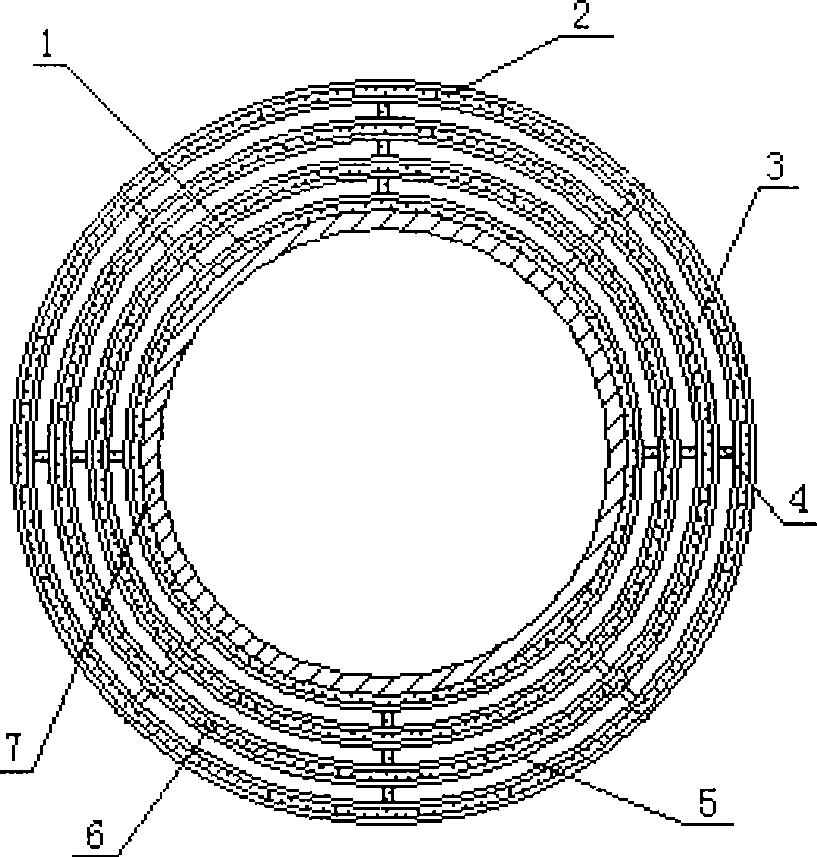

[0046] Embodiment 3: a kind of multi-wall interlayer hollow plastic insulation, cold insulation pipeline, such as Figure 6 , as shown in Figure 10, when extruding the outer pipe wall (2), hollow pipe wall (6) and planting reinforcement (4) with a wall thickness less than 2mm, the pipe wall and planting reinforcement can be made into a mixture of plastics and aluminum powder tendon, wall. It is processed with six-wall five-layer rib composite pipe head and two extruders. The first extrudes the mixed outer pipe wall (10), mixed planted ribs (11), and mixed hollow pipe wall (12), and the second extrudes The inner pipe wall (1) is made of a multi-wall interlayer hollow plastic pipe.

[0047] Thin-walled tube hollow tube wall (6) planting bar (4) dovetail body bar (18) slit (22) is extruded once and made with multi-wall composite tube (16 walls and 17 bars) machine head. The hollow pipe wall (6) utilizes the thickness of the ribs between the rib walls (59) of the sizing sleeve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com