Composite layered structure thermal insulation material high in thermal insulation efficiency

A technology of structural thermal insulation and composite layer, which is applied in thermal insulation, building components, climate change adaptation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

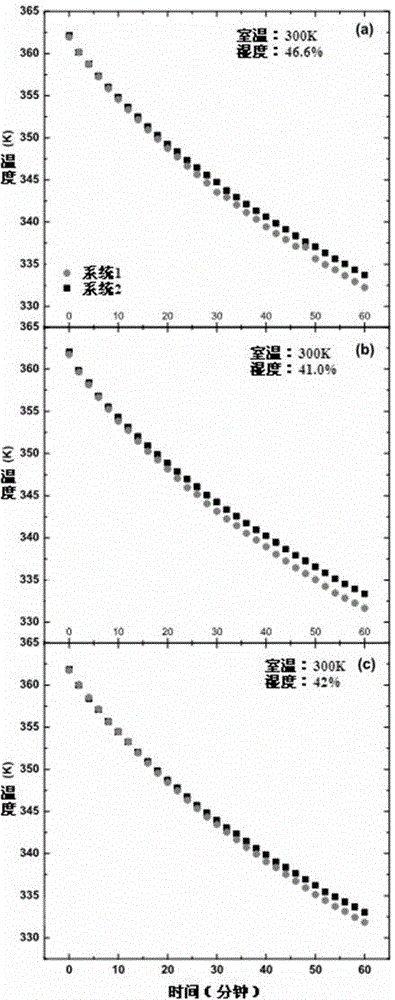

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The basic idea of the present invention is to reduce the radial thermal conductivity or increase the radial thermal conductivity insignificantly, by effectively reducing the heat loss caused by heat radiation and heat convection to achieve the heat preservation effect.

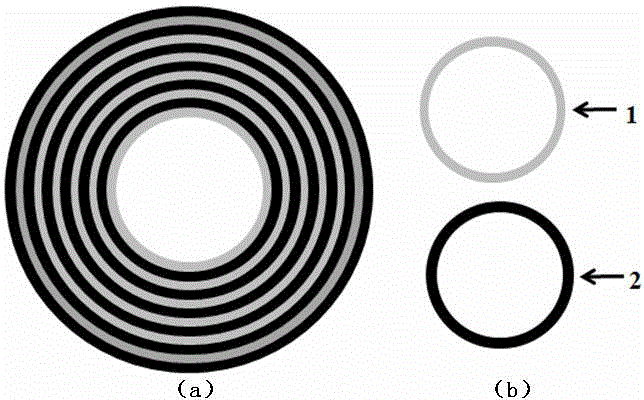

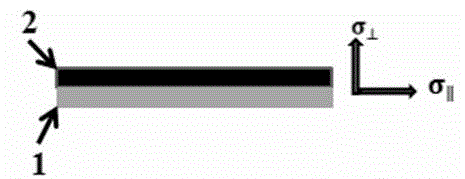

[0023] The present invention designs a composite layered structure to improve thermal insulation efficiency. The structure is composed of thermally high reflectivity materials and low thermal conductivity materials that are compositely arranged into a layered structure or a concentric structure (that is, concentric rings or concentric spirals and other concentric structures) . Taking concentric rings as an example, its structure is as follows figure 1 shown. The structure includes: a high-reflectivity material with a ring-shaped cross section (the test experiment uses aluminum as an e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com