Method and device for producing polyester polyol, polyester polyol and polurethane foam

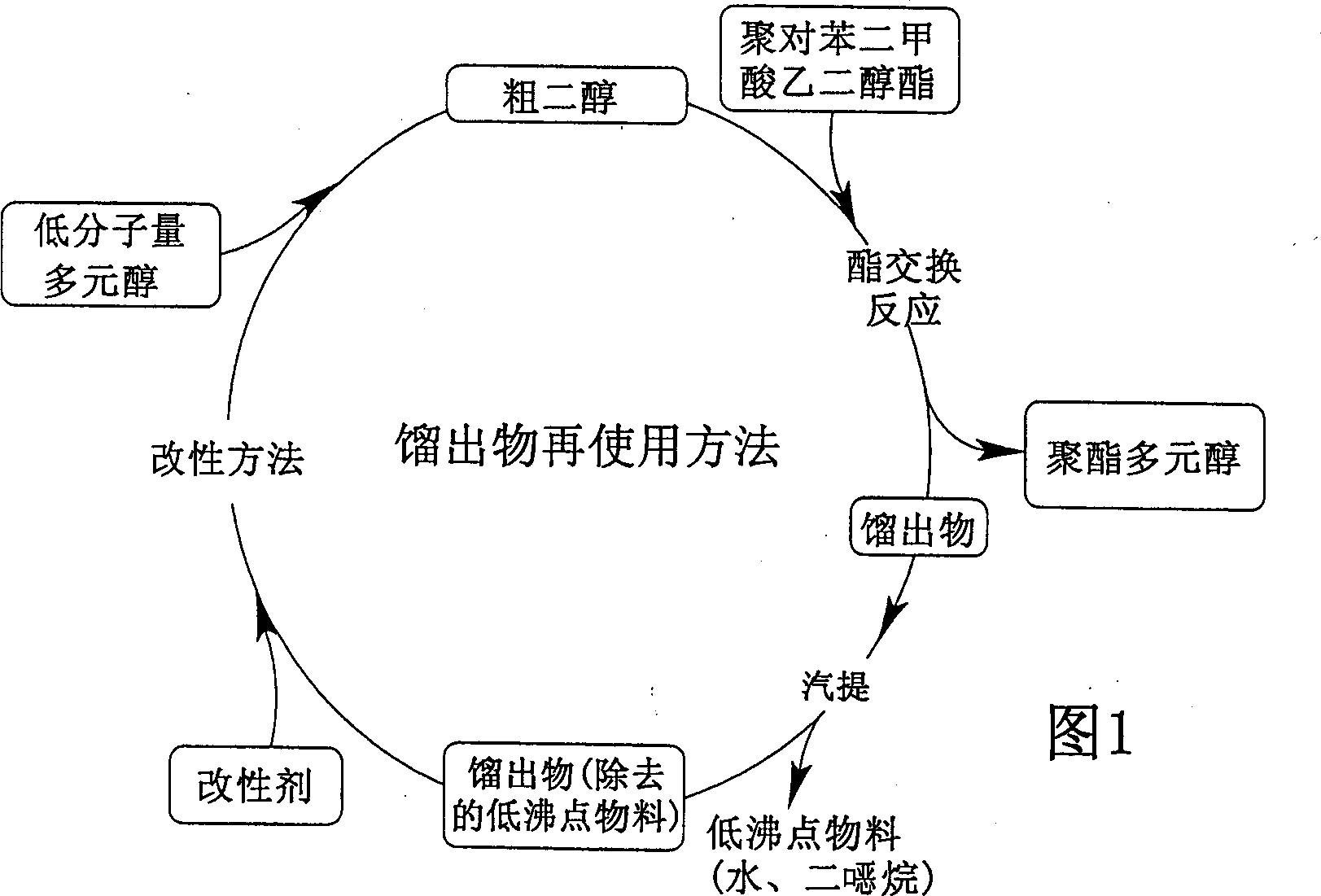

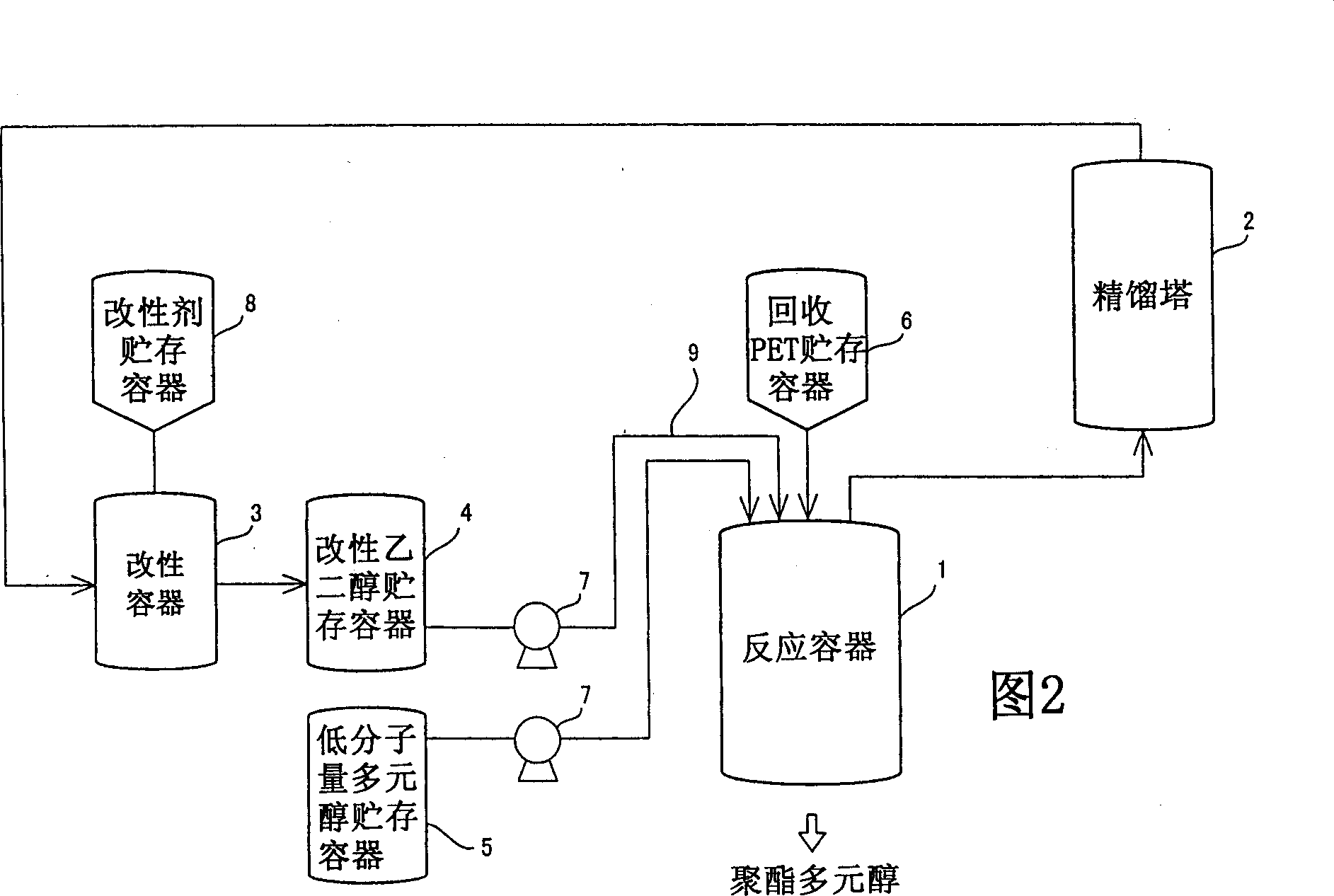

A technology of polyester polyol and polyol, which is applied in the field of polyurethane foam and equipment for producing polyester polyol, can solve problems such as increased viscosity, complicated equipment, and white turbidity of polyester polyol, so as to improve production efficiency and realize Efficient utilization and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The production of embodiment 1 distillate:

[0059] 500 g of PET bottle fragments IFN-10 (available from ARK Co., Ltd.) and 465 g of diethylene glycol were added to a 1,000 ml four-necked flask equipped with a stirrer, a thermometer, a nitrogen inlet tube and a rectification tower, and The reaction was carried out by stirring in the presence of 200 ppm tetrabutoxytitanium at 220-240° C. while injecting nitrogen. The PET bottle fragments started to dissolve at 220°C. The by-product of ethylene glycol was distilled off with nitrogen and after 20 hours the reaction was stopped by cooling. The distillate obtained was 150 g. The composition of the distillate included 6% water, 70% ethylene glycol, 22% diethylene glycol, and 2% dioxane. After forcibly stripping low-boiling content from the distillate at 130° C. with nitrogen over 30 minutes, the distillate became 135 g and had a hydroxyl value of 1,500 mgKOH / g. Modification method:

[0060] 127 g ...

Embodiment 2

[0063] With 200g of PET bottle fragments IFN-10 (available from ARK Co., Ltd.), the modified oxirane solution (hydroxyl value 660mgKOH / g) that 140g obtains in the polyester polyol production method of embodiment, and 140 g of diethylene glycol were added to a 1,000 ml four-necked flask equipped with a stirrer, a thermometer, a nitrogen gas introduction tube, and a rectification tower, and nitrogen was injected at 220-240 ° C in the presence of 200 ppm tetrabutoxytitanium The reaction is carried out by stirring. The PET bottle fragments started to dissolve at 220°C. The by-product of ethylene glycol was distilled off with nitrogen and after 20 hours the reaction was stopped by cooling. The distillate obtained was 70 g. The obtained polyester polyol was a transparent brown liquid having a hydroxyl value of 310 mgKOH / g and a viscosity of 1,800 mPas / 25°C. None of white turbidity, increased viscosity, and crystallization occurred in the polyester polyol after storage at room tem...

Embodiment 3

[0065] After adding 30 g of diethylene glycol to 100 g of the distillate (hydroxyl value 1,500 mgKOH / g) obtained in the distillate production method of Example 1, 1.0 g of potassium hydroxide was chipped at 130° C. Dissolved therein and then continuously added 128 g of propylene oxide to react therewith. After the reaction was finished, 5 g of water and 3.0 g of KYOWAAD 600 (an amphoteric adsorbent available from Kyowa Chemical industry Co., Ltd.) were added in order to remove the added potassium hydroxide. After the dehydration and filtration process was completed, an ethylene glycol mixture with a hydroxyl value of 700 mgKOH / g was obtained.

[0066] Then, 200 g of PET bottle fragments IFN-10 (available from ARK Co., Ltd.) and 260 g of the above-mentioned ethylene glycol mixture were charged into a 1,000 ml four-necked flask equipped with a stirrer, a thermometer, a nitrogen gas introduction tube, and a rectification column. , and the reaction was carried out by stirring whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com