Lithium ion battery for automobile

A lithium-ion battery, automobile technology, applied in the direction of batteries, battery pack components, circuits, etc., can solve the problems of short circuit of positive and negative electrodes, simple structure, inconvenient maintenance and repair, etc., to prevent short circuit of positive and negative electrodes, and to achieve reasonable design , the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0041] Example.

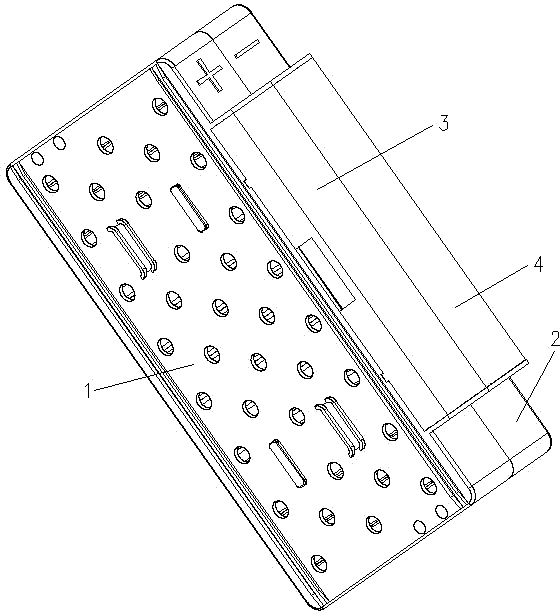

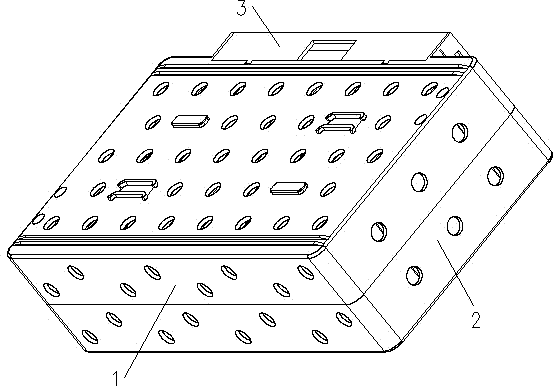

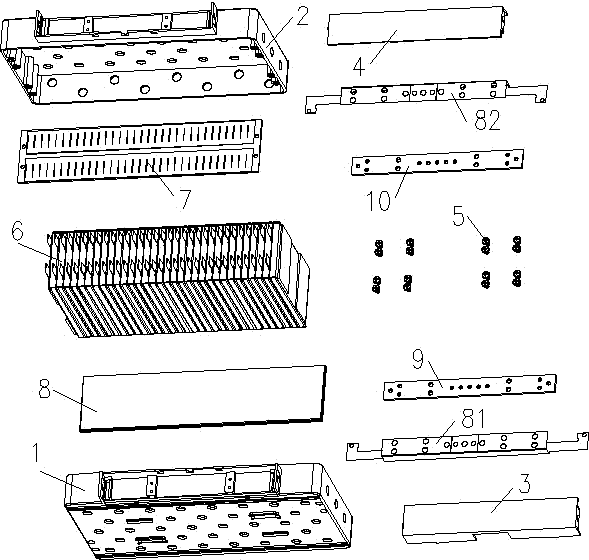

[0042] see Figure 1 to Figure 23 , the lithium-ion battery for automobiles in this embodiment includes a left half case 1, a right half case 2, a left cover 3, a right cover 4, several screws 5, a cell pack 6, an adapter plate 7, silica gel Pad 8, left conductive strip 9, right conductive strip 10, left terminal connecting strip 81 and right terminal connecting strip 82, wherein, left conductive strip 9 and right conductive strip 10 are usually made of copper, that is, usually copper strips, and screw 5 is usually For M4 screws, several holes are provided on the left conductive strip 9 and the right conductive strip 10, the adapter plate 7 is fixed on the battery pack 6, the left half-shell 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com