Prestressed concrete steel bar platform processing equipment

A technology for concrete steel rods and processing equipment, applied in the field of steel rod platforms, which can solve the problems affecting the convenience of prestressed concrete steel rod platforms, intermittent connection of patterns, time-consuming and labor-intensive problems, etc., to increase rolling pressure and buffering, and increase friction , to avoid the effect of stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

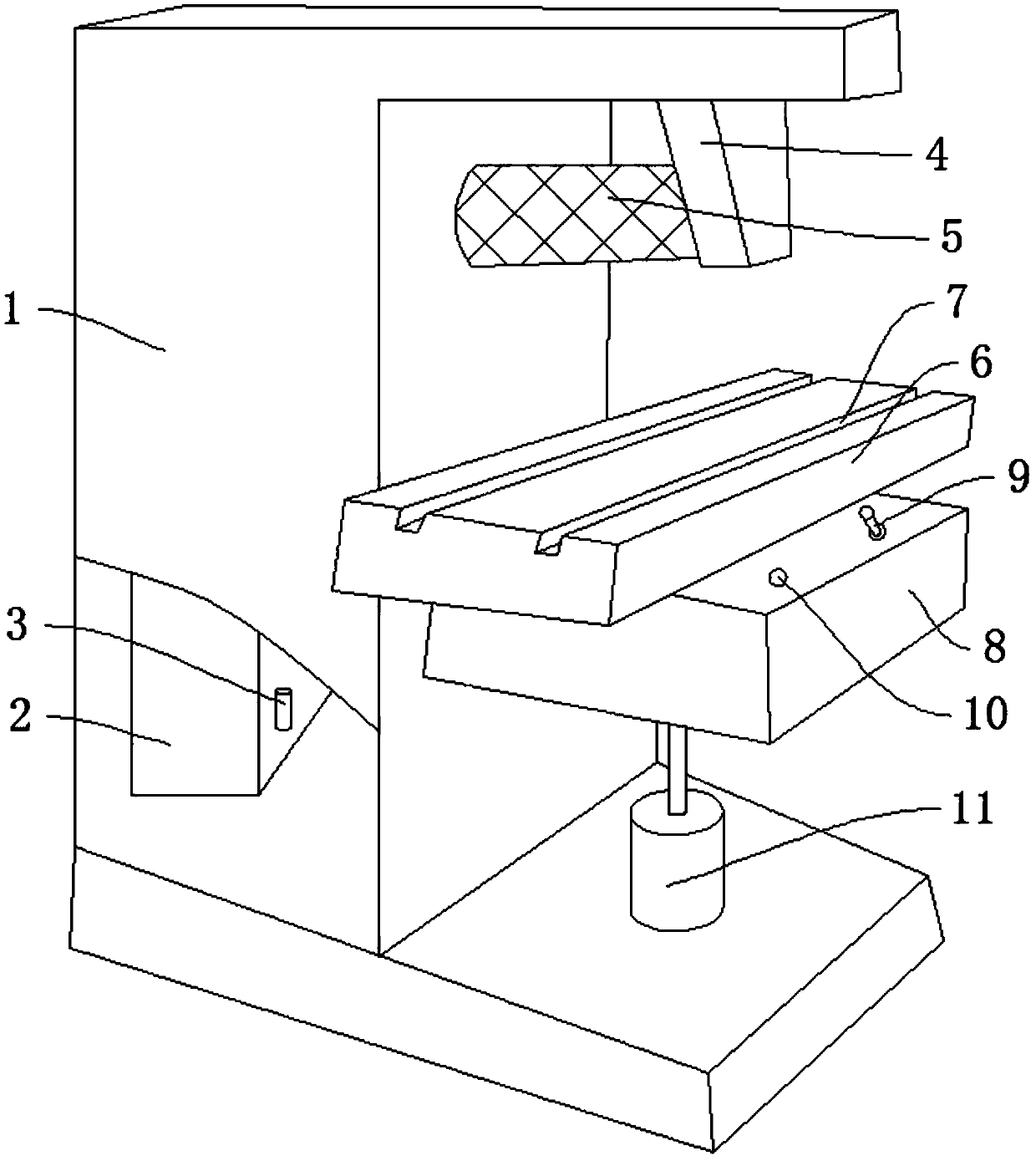

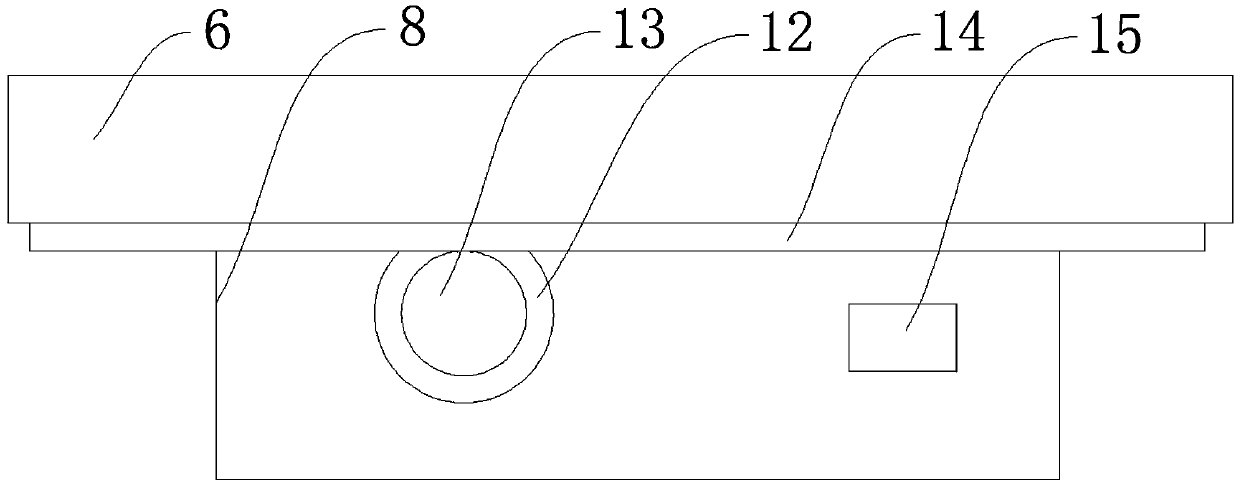

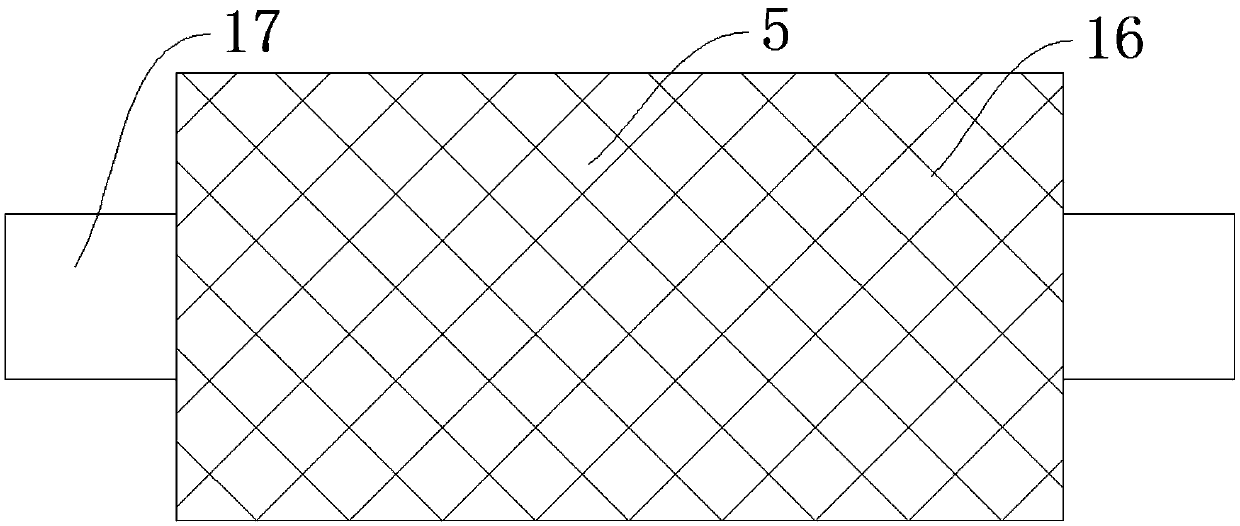

[0034] Such as Figure 1-Figure 4 As shown, a prestressed concrete steel bar platform processing equipment includes a support frame 1, a support box 8, and a support platform 6. The support frame 1 is provided with a hydraulic tank 2 containing hydraulic oil, and one side of the hydraulic tank 2 is provided with hydraulic Pump 3, boost power, support frame 1 is provided with a support base 4 on the top, supporting squeeze roller 5, a squeeze roller 5 is provided on one side of the support base 4, a squeeze steel bar platform, and a rolling pattern is provided on the squeeze roller 5 16. Print the pattern. A support platform 6 is provided under the squeeze roller 5 to support a fixed steel bar platform. A straight rack 14 is provided under the support platform 6 to form meshing transmission with the pinion gear 13, and a support box is provided under the support platform 6. 8. The motor 12 is supported. The motor 12 is provided in the support box 8 to drive the moving power. A p...

Embodiment 2

[0036] The difference between this embodiment and embodiment 1 is:

[0037] Support shafts 17 are provided on both sides of the squeeze roller 5. The support shaft 17 and the squeeze roller 5 are connected by bolts. The support shaft 17 is connected with the support base 4 and the support frame 1 by bearings. The bolt connection is convenient for disassembly and replacement of the support shaft 17. The bearing connection facilitates the flexible rotation of the supporting shaft 17.

[0038] Working principle: Place the steel bar platform on the support platform 6, use a pressure plate and bolts to pass through the dovetail groove 7 to press the steel bar platform on the support platform 6, press the lift key 10, and the hydraulic pump 3 will place the hydraulic box 2 The hydraulic oil is added to the lifting cylinder 11. The lifting cylinder 11 pushes the support platform 6 up to press the steel bar platform under the squeeze roller 5, pushing the feed rod 9, the motor 12 drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com