Method for carrying out cutter back-off compensation on multi-shaft processing path of weak-rigidity cutter

A multi-axis processing and processing path technology, applied in the direction of instruments, computer control, simulators, etc., to achieve the effects of suppressing the size of parts out of tolerance, ensuring one-time molding, and ensuring processing efficiency and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only parts related to the present invention are shown in the drawings but not all content.

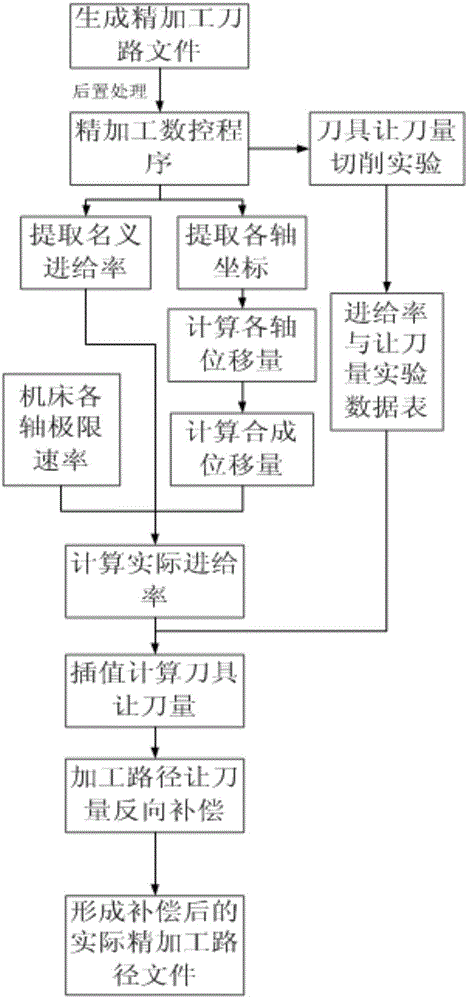

[0031] Please refer to figure 1 as shown, figure 1 It is a flow chart of a method for tool clearance compensation for a multi-axis machining path of a weakly rigid tool provided by an embodiment of the present invention.

[0032] In this embodiment, the method for performing tool yield compensation on the multi-axis machining path of a weakly rigid tool specifically includes the following steps:

[0033] S101. Generate a finishing tool path file according to the geometric shape and process parameters of the part, and perform post-processing to convert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com