Belt disengagement prevention radiator guard board and radiator core

A radiator and anti-dropping technology, which is applied in the direction of heat exchanger shell, heat exchanger fixing, heat exchange equipment, etc. hidden dangers, good promotion and use value, and simple molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

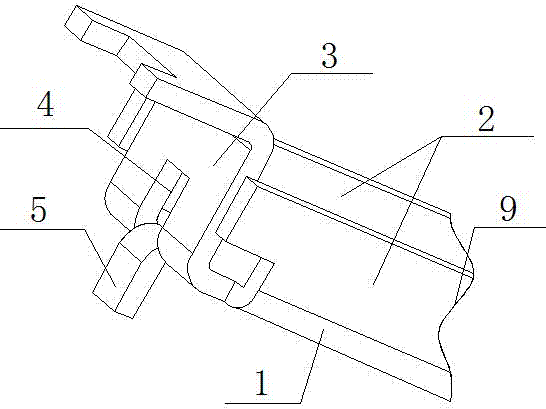

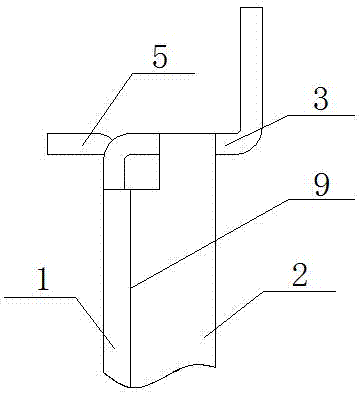

[0023] A radiator guard plate with an anti-off strip of the present invention includes a main body 1, a flange portion 2 and a bending portion 3, the flange portion 2 is arranged on both sides of the main body 1, and the bending portion 3 is arranged on the main body 1; at the center of the junction of the main body 1 and the bending part 3, a through hole 4 is opened, and one end of the through hole 4 is fixed with a claw 5, the top of the claw 5 is a strip-shaped structure, and the tail end It is an arc-shaped plate structure, the bending direction of the claw 5 is opposite to that of the bending part 3, and the top end of the claw 5 and the main body 1 are arranged at 90° to each other, and the claw 5 and the bending part 3 are integrally structured.

Embodiment 2

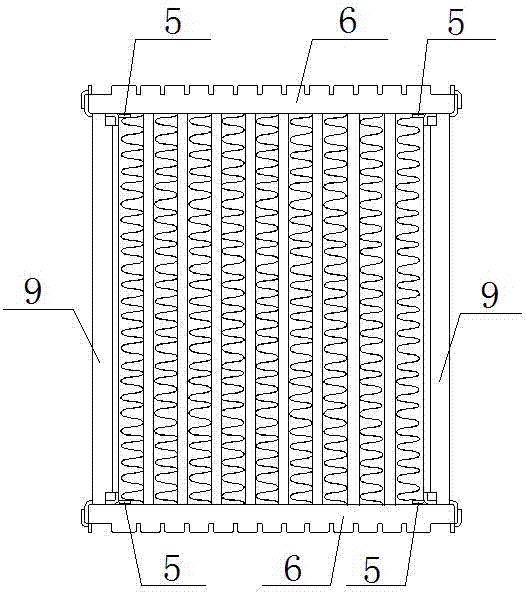

[0025] The radiator core of the present invention comprises two radiator main pieces 6, heat dissipation strips 7 and heat dissipation pipes 8, and the two ends of 10 heat dissipation pipes 8 arranged side by side are respectively connected to the two radiator main pieces 6 arranged in parallel. , the heat dissipation belt 7 is arranged between two adjacent heat dissipation pipes 8; it also includes a radiator guard plate 9, and the radiator guard plate 9 is any one of the radiator guard plates 9 of the anti-off band in embodiment 1, a pair of The radiator guard plate 9 is arranged in parallel between the two radiator main sheets 6 and is respectively located on both sides of the radiator main sheet 6, and is vertically arranged with the radiator main sheet 6; The ends of the two radiator main pieces 6 on the same side are fixedly connected; the claws 5 at both ends of the radiator guard plate 9 are in contact with the heat dissipation belts 7 at both ends of the radiator guard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com