Equipment and method for manufacturing corrugated type glass fiber reinforced plastics integrally-formed cylinder

A technology of integral forming and manufacturing method, which is applied to the manufacturing equipment and manufacturing field of corrugated glass fiber reinforced plastic integral forming cylinder, can solve the problems of inability to carry out large-scale large-scale production, occupational health impact of workers, and inability to guarantee product quality. The area is popularized and used to ensure large-scale mass production and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

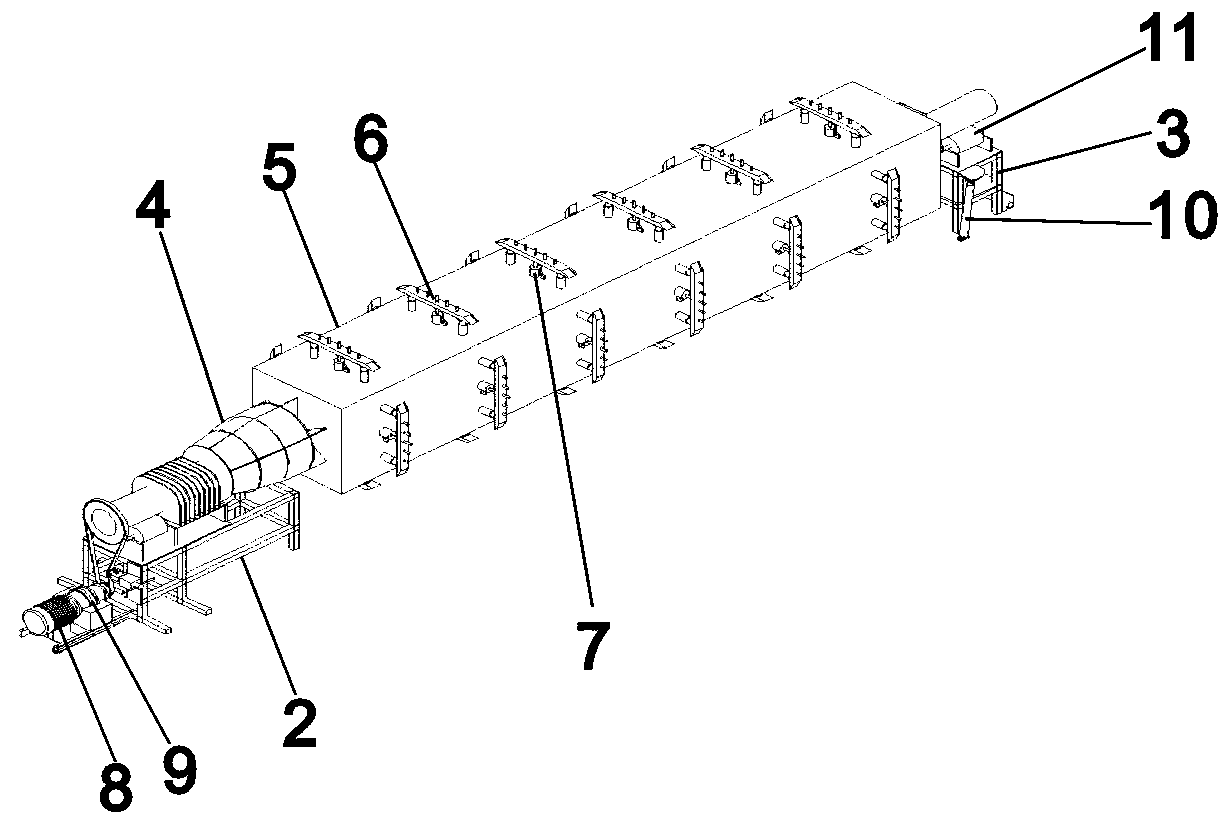

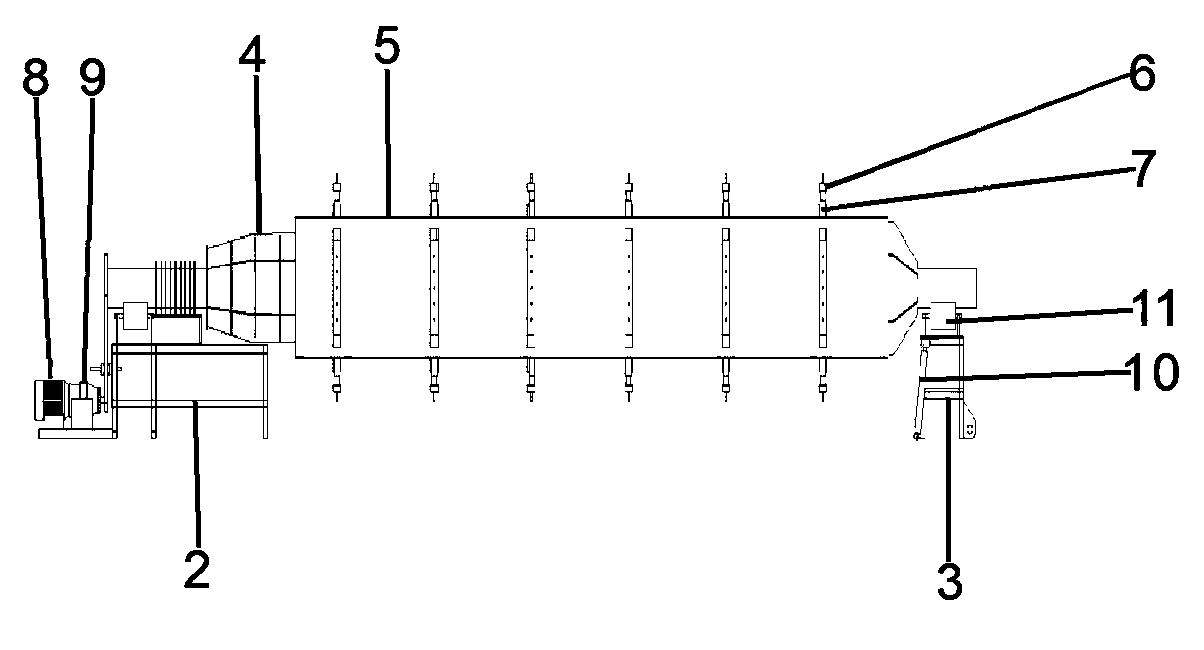

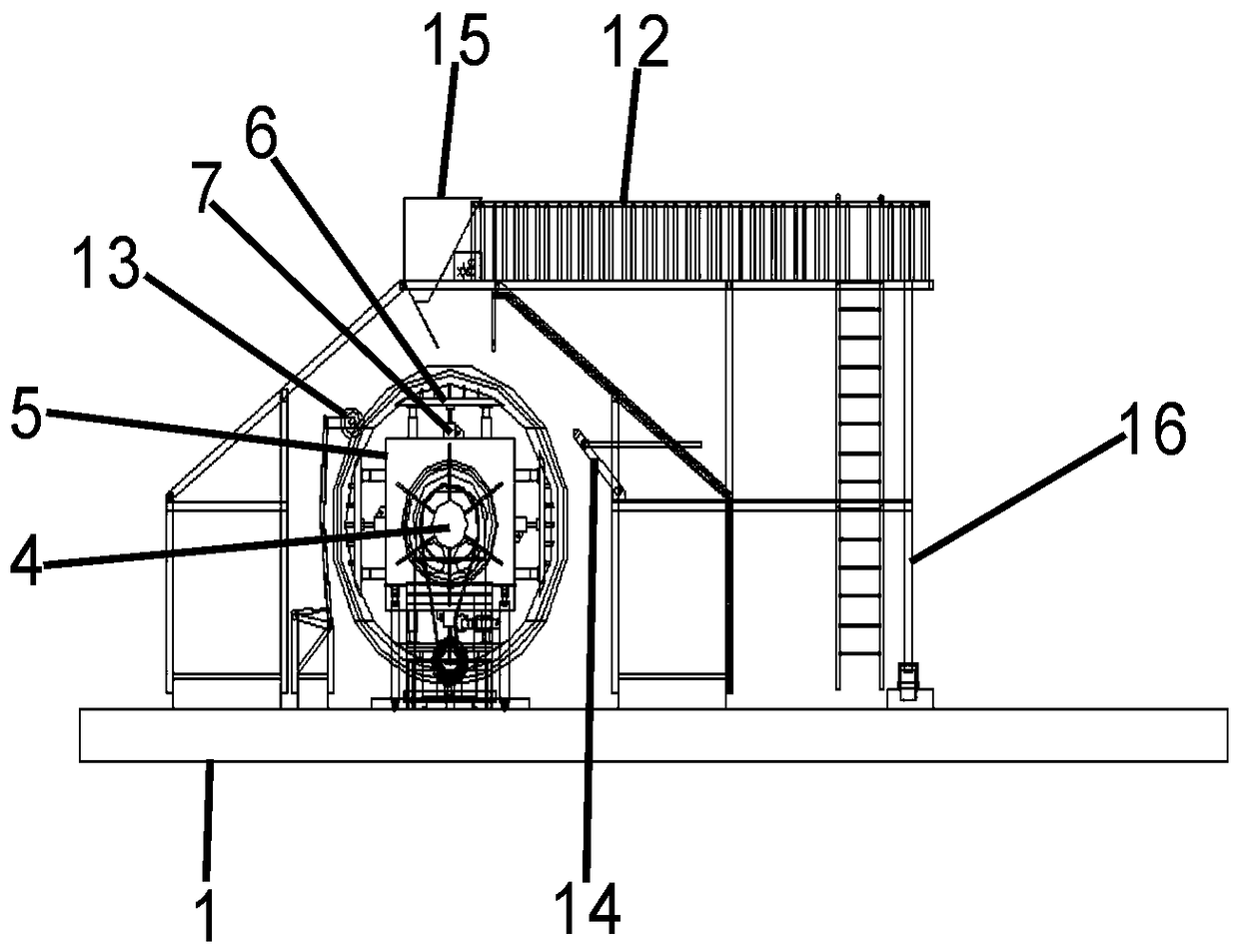

[0018] The following will be combined with figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 To further describe the present invention:

[0019] as attached figure 1 , attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 As shown, a corrugated glass fiber reinforced plastic integral molding cylinder manufacturing equipment and manufacturing method, including a working platform (1), characterized in that: the working platform (1) is provided with a front support seat (2) and a rear support seat (3), the front support seat (2) and the rear support seat (3) are provided with a rotating crossbeam (4), and the formwork (5) is overcoated on the revolving crossbeam (4), and the four sides of the formwork (5) are Each is equipped with a telescopic block (6), and the telescopic block (6) is connected with the formwork (5) through a hydraulic telescopic guide mechanism (7), and a drive mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com