Explosive column for smooth blasting excavation of foundation surface and excavation technology

A technology for building a foundation surface and explosives, applied in blasting and other directions, can solve the problems of limited blasting shock wave buffering effect, large amount of manual prying, low construction efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

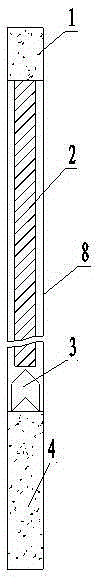

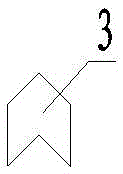

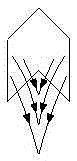

[0030] like figure 1 , 2 As shown, a kind of explosive column used for blasting and excavation of foundation surface, which comprises rows of vertical blastholes 8 that are located in the center of the rock mass, a buffer layer 4, a rigid cushion layer 3, a buffer layer 4 at the bottom of the blasthole holes, Explosive 2, blocking section 1, buffer layer 4, rigid cushion 3, explosive 2, blocking section 1 are stacked in order from bottom to top. The buffer layer 4 is a cylinder, the diameter of which is smaller than the diameter of the blasting hole by 0.5-1 cm, so that it can be put into the blasting hole smoothly, and the height of the buffer layer 4 is 10-40 cm. The thickness of the buffer layer laid in each blast hole is the same, and the buffer layer is made of foamed concrete.

[0031] The upper and lower surfaces of the rigid cushion la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com