Preparation mould and method of ceramic-based corrugated wing air inlet leading-edge panel

A technology of an air inlet and a leading edge plate, which is applied to the preparation mold and field of a leading edge plate of an air inlet of a ceramic-based corrugated airfoil, can solve the problem of small space utilization, poor heat insulation effect of a solid plate, and increased front air intake. Edge quality and other issues to achieve the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

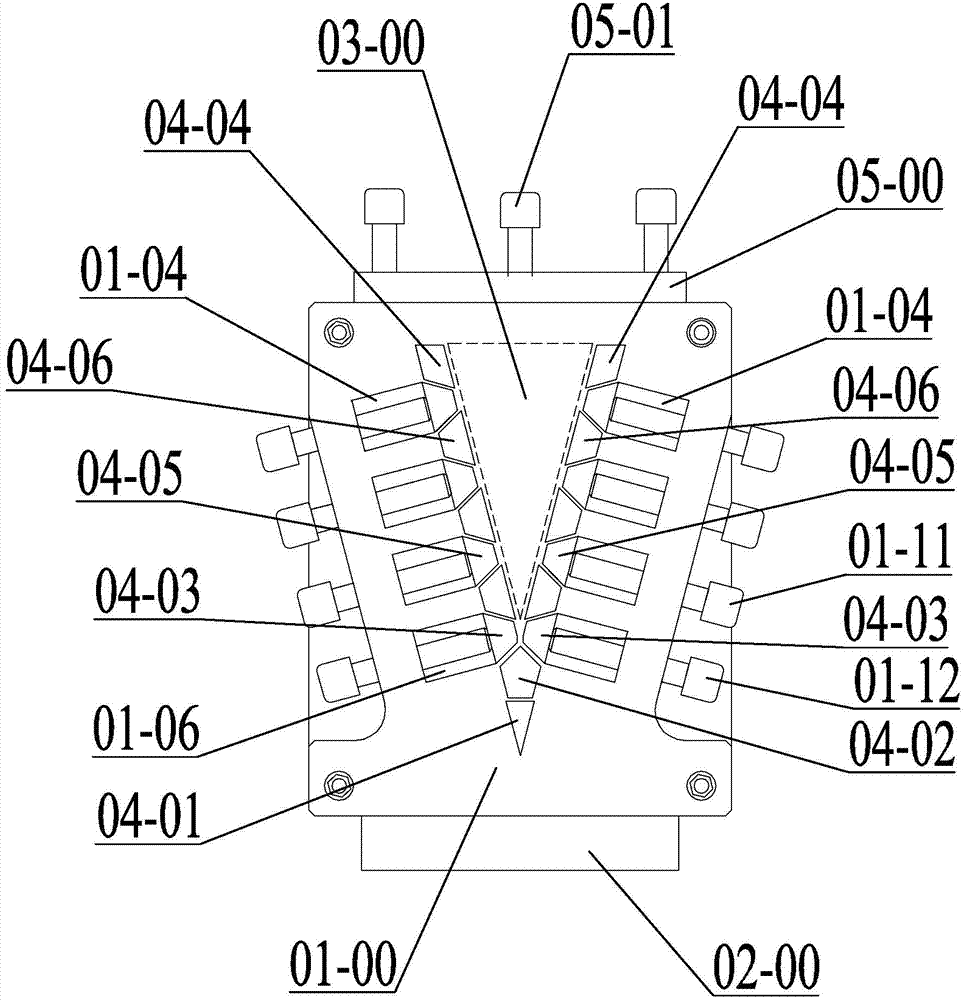

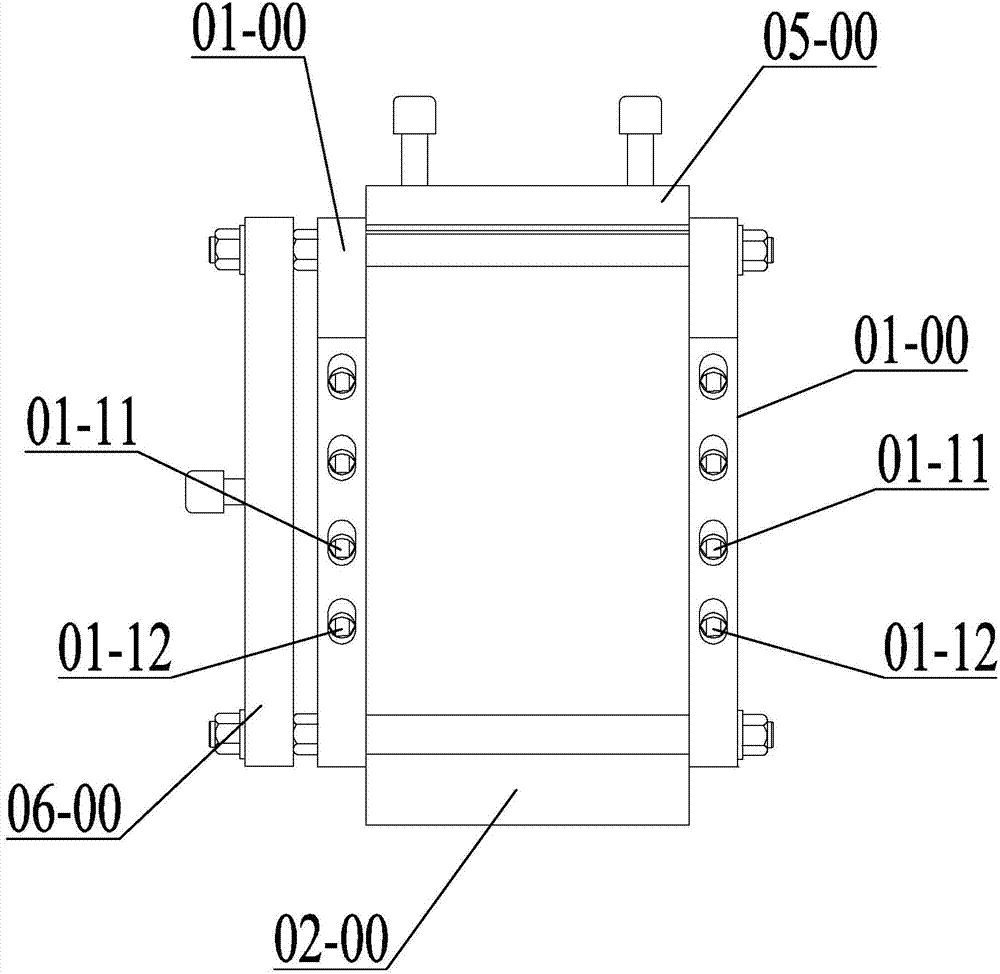

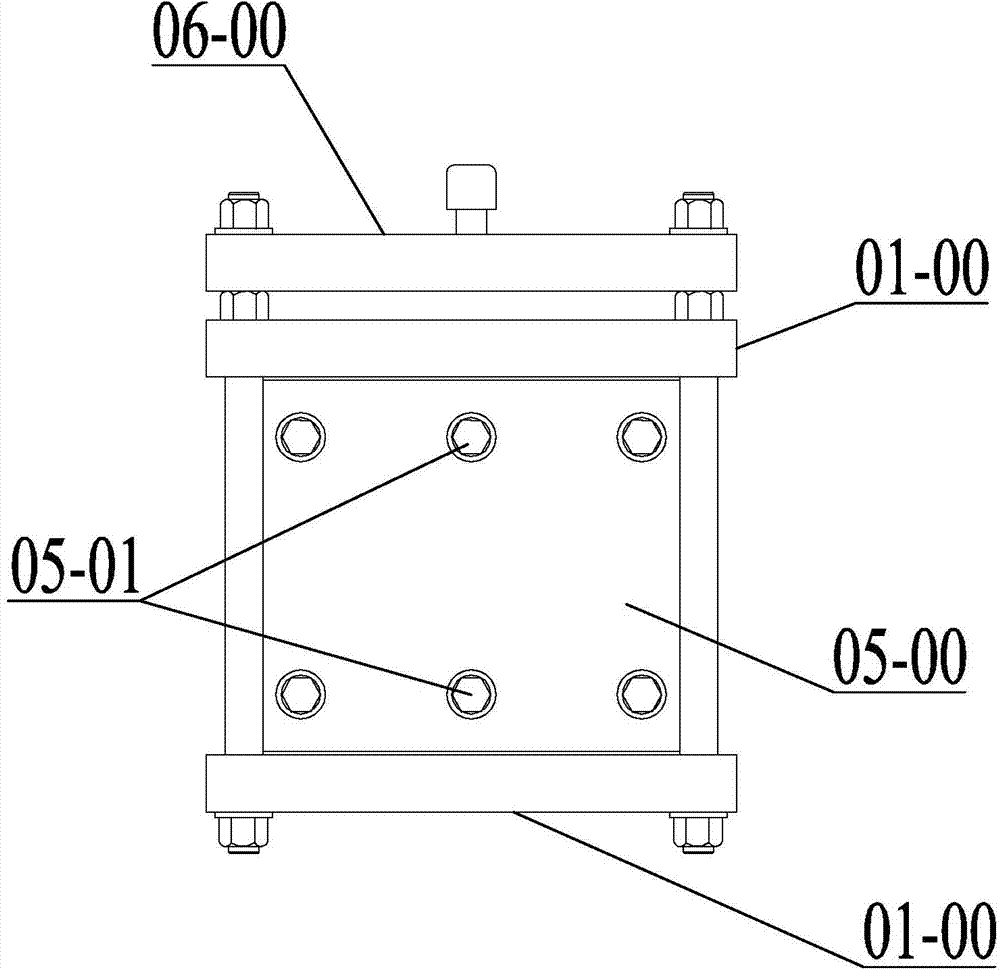

[0031] Specific implementation mode one: combine Figure 1 to Figure 15 Explain that the mold in this embodiment includes a concave block 02-00, a convex block 03-00, a convex block pressing plate 05-00, a triangular long block 04-01, a pentagonal long block 04-02, and two main bodies Plate 01-00, two trapezoidal strips with missing corners 04-03, two end trapezoidal strips 04-04 and two trapezoidal strip groups,

[0032] The top surface of the concave block 02-00 is provided with a triangular through groove 02-01 along the horizontal direction, and the shape of the convex block 03-00 is consistent with the shape of the triangular through groove 02-01 and placed in the triangular through groove 02-01.

[0033] The two main boards 01-00 are arranged vertically opposite to each other at both ends of the triangular through slot 02-01, and the two main boards 01-00 are detachably fixed by several threaded connectors.

[0034] The triangular strip 04-01 and the pentagon strip 04-02 ...

specific Embodiment approach 2

[0051] Specific implementation mode two: combination Figure 1 to Figure 15 Note that the mold in this embodiment also includes dismantling the strip plate 06-00. It is detachably connected to the main body plate 01-00 through threaded connectors, and the surface of the strip plate 06-00 is provided with several fourth threaded through holes 06-01, and several fourth threaded through holes 06 The arrangement of -01 is the same as that of the triangular through-hole 01-01, pentagonal through-hole 01-02, two trapezoidal through-holes with missing corners 01-07, and two trapezoidal through-holes at the end 01-01- 08. The arrangement of the first trapezoidal through holes 01-03 and the second trapezoidal through holes 01-05 is consistent, and each fourth bolt is screwed into a fourth threaded through hole 06-01.

[0052] All the strips can be removed smoothly and the disassembly speed of the strips can be improved by using the dismantling strip plate 06-00. During the use of the ...

specific Embodiment approach 3

[0054] Specific implementation mode three: combination Figure 1 to Figure 15 Note that the moving trapezoidal strips 04-05, the missing corner trapezoidal strips 04-03 and the fixed trapezoidal strips 04-06 in this embodiment are all isosceles trapezoidal strips with the same shape, and the isosceles trapezoidal length The included angle between the waist plane of the bar and the lower bottom plane is 10 degrees to 75 degrees, and the waist plane of any adjacent moving trapezoidal long bar 04-05 and the fixed trapezoidal long bar 04-06 are set relatively parallel, and the trapezoid with missing corners The waist planes of the elongated blocks 04-03 and the adjacent fixed trapezoidal elongated blocks 04-06 on the same side are relatively parallel to each other.

[0055] The undisclosed technical features in this embodiment are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com