Wet type isostatic cool pressing die

A technology of cold isostatic pressing and moulds, which is applied in the direction of moulds, manufacturing tools, ceramic molding machines, etc., which can solve problems such as uneven pressure, long production process, and increased production costs, so as to improve production efficiency and reduce processing allowance , the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments are provided below and the present invention is further described in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

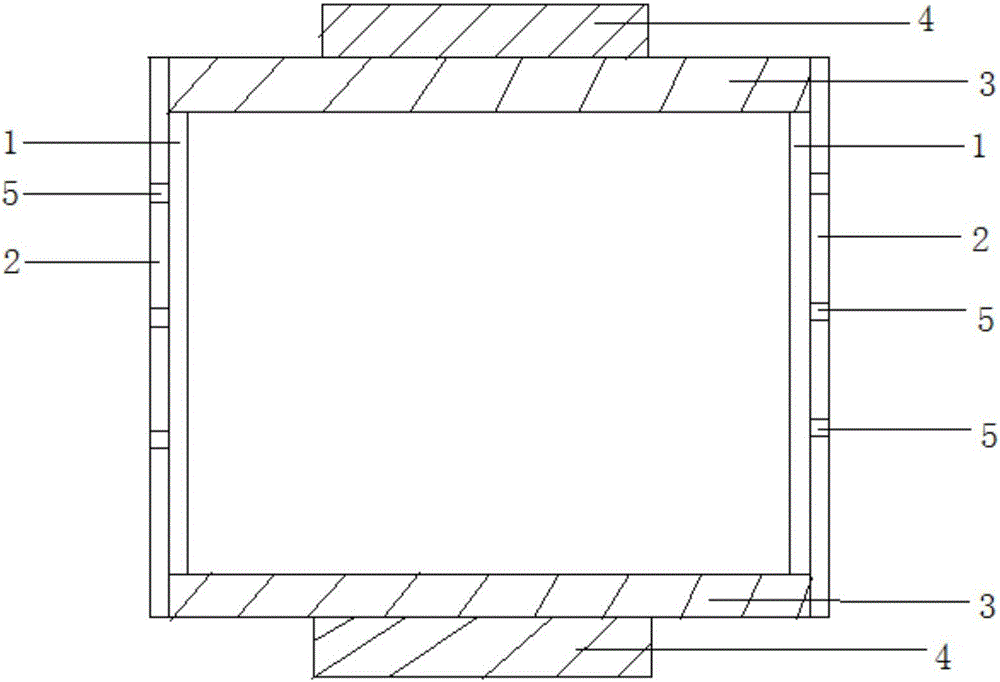

[0022] like figure 1 As shown, the wet cold isostatic pressing mold of the present invention is a composite mold made of various materials, including a mold body and a mold cover plate 3, wherein the mold body is composed of a soft inner sleeve 1 and a control mold 2 , a number of diversion holes 5 are distributed on the control-type master mold 2 .

[0023] The soft inner sleeve 1 is made of high-toughness, high-pressure-resistant organic material, has a certain thickness, and is mainly used to control the flow of powder. Specifically, the soft inner sleeve 1 can be made of rubber or its derivative products with a thickness of 0.1-5.0mm and a pressure resistance of 220Mpa≥P≥60Mpa, such as fluororubber, silicone rubber or epichlorohydrin rubber. The soft inner slee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com