Method for repairing metal surface micro-cracks based on laser micro-fusion

A metal surface, micro-crack technology, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problems affecting the effect of crack repair, physical property mismatch, etc., to achieve high production efficiency, saving resources and costs, no Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

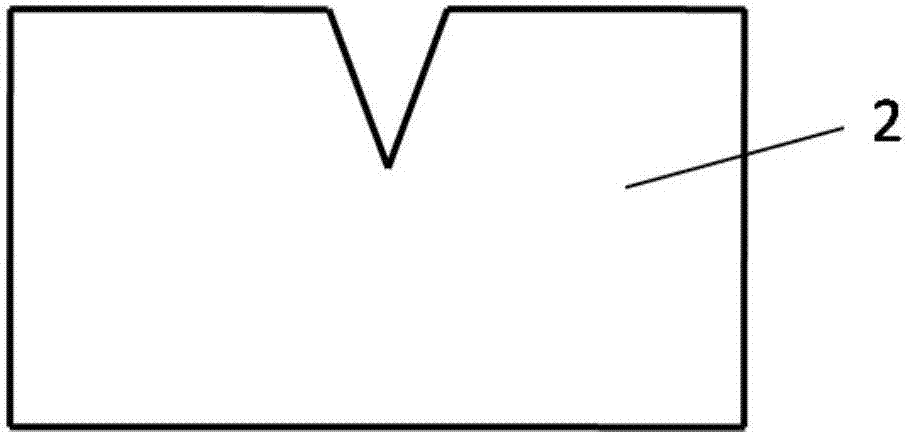

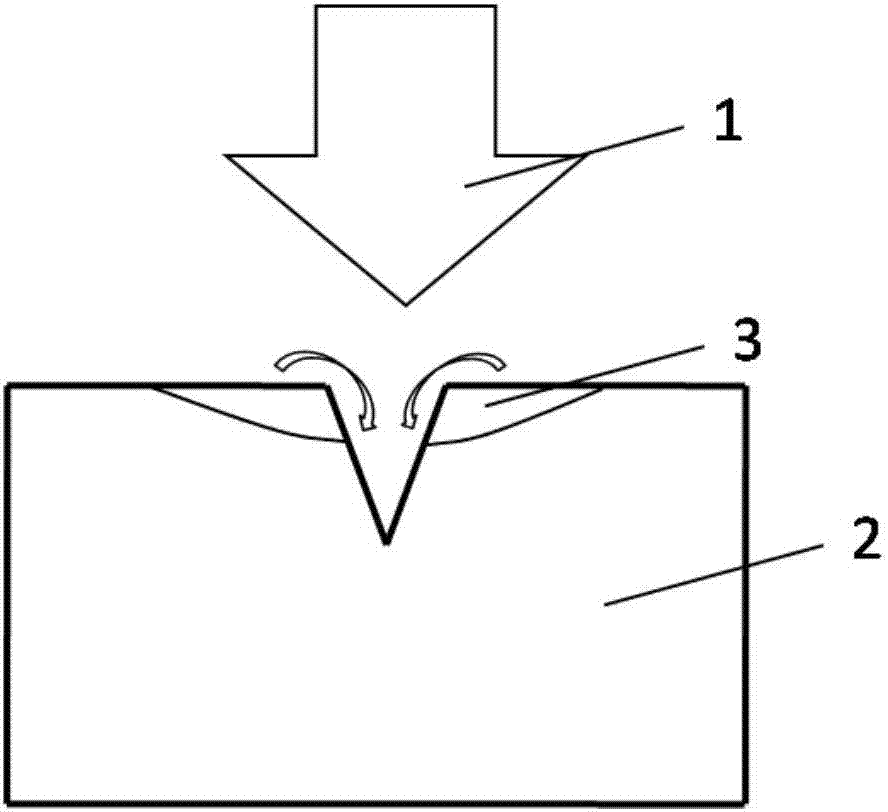

[0022] A method for bridging microcracks on the metal surface by laser micro-melting according to the present invention is: use a long pulse laser beam or a continuous laser beam with a pulse width greater than 100 microseconds to scan the microcrack area on the surface of the metal workpiece, and the size of the microcracks is between At the nanometer or micrometer level, the thermal effect of the laser is used to slightly melt the microcrack area on the surface of the metal workpiece to form a metal liquid. The metal liquid flows, flows into the microcrack area and then solidifies, thereby achieving the effect of bridging the cracks on the metal surface. The average power density of the laser beam should be in the range of 1*10^5W / cm^2 to 10*10^5W / cm^2 to ensure that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com